Special skin-like dust-proof powdery coating for radiator, and preparation method and application thereof

A powder coating and skin-feeling technology, applied in powder coatings, anti-fouling/underwater coatings, conductive coatings, etc., can solve problems such as patent publications that have not yet been found, achieve strong practical value, prevent dust adsorption, and eliminate static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

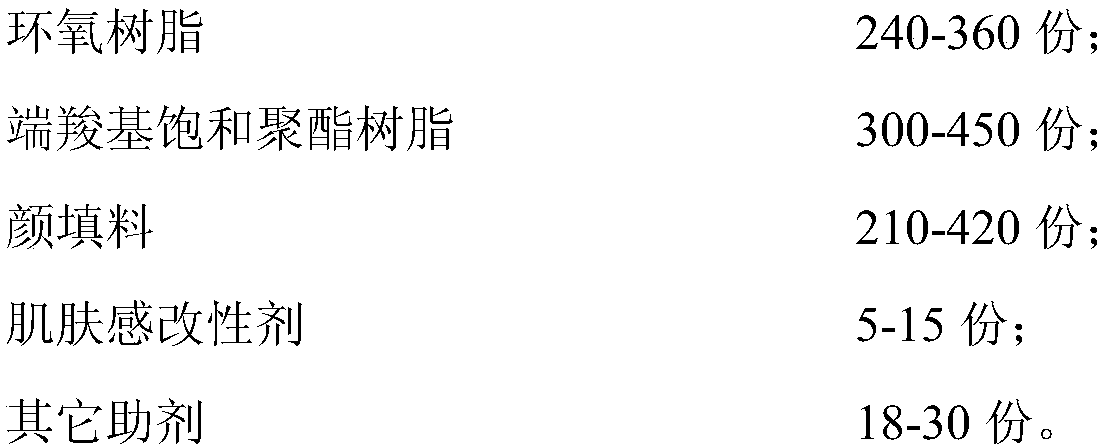

[0026] A special skin-feeling dust-proof powder coating for radiators, its raw material components and parts by weight are as follows:

[0027]

[0028]

[0029] Described epoxy resin is glycidyl ether epoxy resin, epoxy equivalent 730-850g / eq;

[0030] The acid value of the carboxyl-terminated saturated polyester resin is 50-56 mgKOH / g;

[0031] The pigments and fillers are composed of ultrafine barium sulfate, ultrafine rutile titanium dioxide and inorganic pigments;

[0032] The skin sensitivity modifier is a modified organosilicon polymer;

[0033] The other additives are a mixture of leveling agent, anti-jamming agent and degassing agent.

[0034] The preparation method of the special skin feeling dust-proof powder coating for radiator as above, the steps are as follows:

[0035] 1) Add fillers and skin feel modifiers to the high-speed mixer in parts by weight, disperse at high speed (400-1000r / min) for 30-60 minutes, and disperse the skin feel modifiers into the...

Embodiment 2

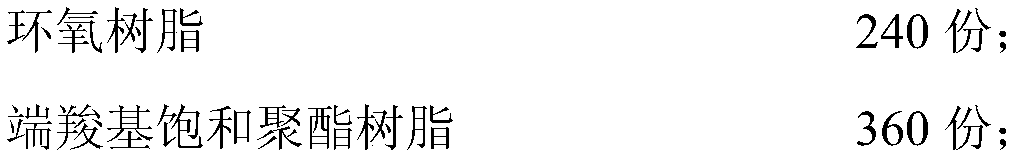

[0038] A special skin-feeling dust-proof powder coating for radiators, its raw material components and parts by weight are as follows:

[0039]

[0040] Preferably, the epoxy resin is a glycidyl ether epoxy resin with an epoxy equivalent of 730-850 g / eq.

[0041] Preferably, the acid value of the carboxyl-terminated saturated polyester resin is 50-56 mgKOH / g.

[0042] Preferably, the pigments and fillers are composed of ultrafine barium sulfate, ultrafine rutile titanium dioxide and inorganic pigments.

[0043] Preferably, the skin feeling modifier is a modified organosilicon polymer.

[0044] Preferably, the coating film formed by applying the skin-feeling dust-proof powder coating to the radiator feels as smooth and delicate as skin, and can eliminate static electricity so as to prevent dust from being adsorbed.

[0045] Preferably, the other additives are a mixture of leveling agent, anti-interference agent and degassing agent.

[0046] The preparation method of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com