Friction material

A technology of friction materials and particles, which is applied to friction linings, mechanical equipment, and other chemical processes, can solve problems such as easy generation of abnormal noise, achieve suppression of aggressiveness, reduce creep abnormal noise, and ensure anti-braking attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

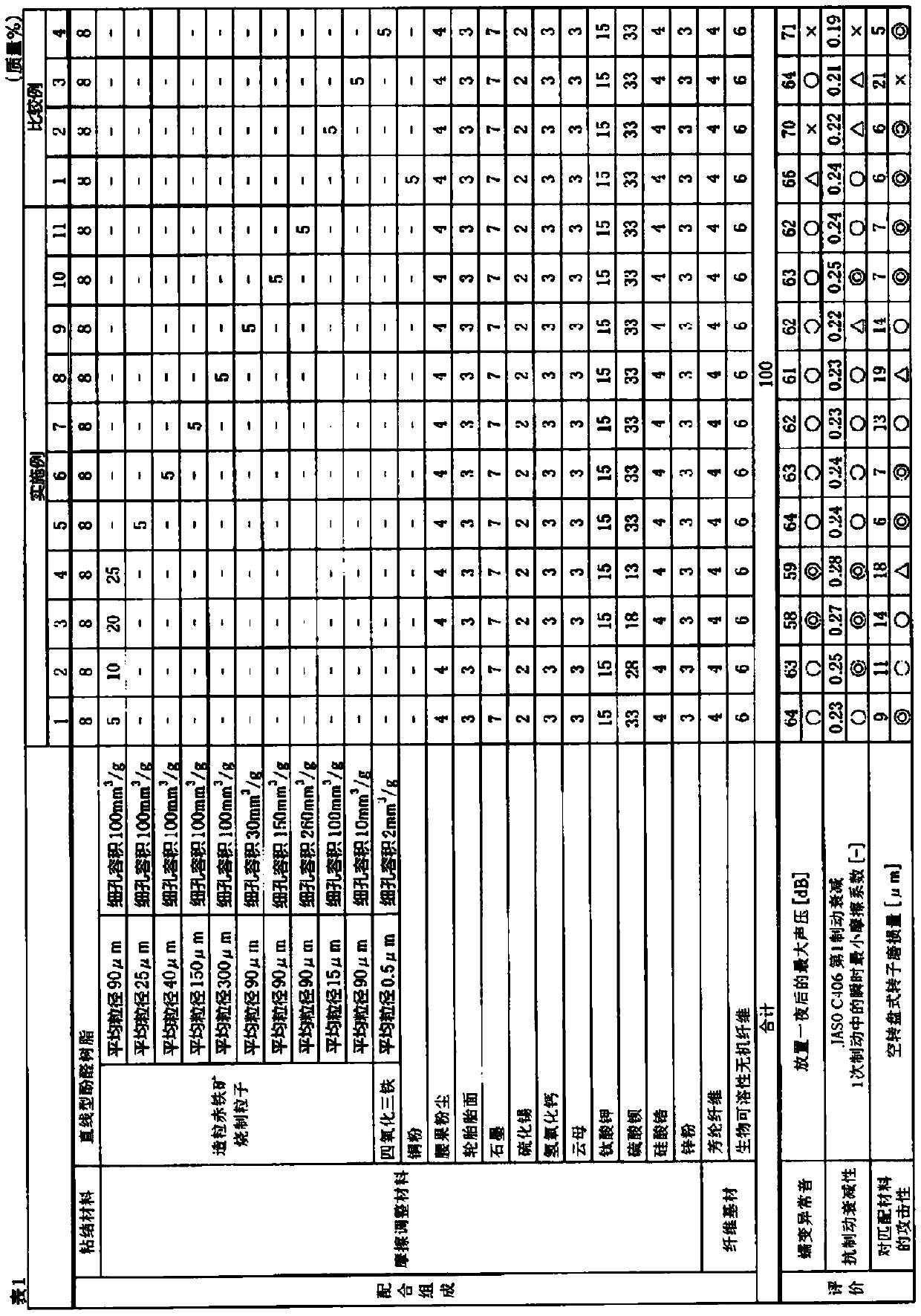

[0082] (Examples 1-11, Comparative Examples 1-4)

[0083]

[0084] The raw materials of the friction material compounding composition shown in Table 1 were mixed for 4 minutes with a mixer, the mixture was put into a mold, and pressurized at a pressure of 20 MPa for 10 seconds to produce a preform.

[0085] The obtained preform was put into a thermoforming mold, the metal plates coated with the adhesive in advance were stacked, and heat compression molding was performed at a pressure of 40 MPa and a molding temperature of 150° C. for 5 minutes to produce a heat compression molded body.

[0086] The obtained heat-compression molded body was heat-treated at 230° C. for 3 hours, polished, and painted to produce the friction materials of Examples 1-11 and Comparative Examples 1-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com