Rolling bearing, and main shaft support device for wind power generation

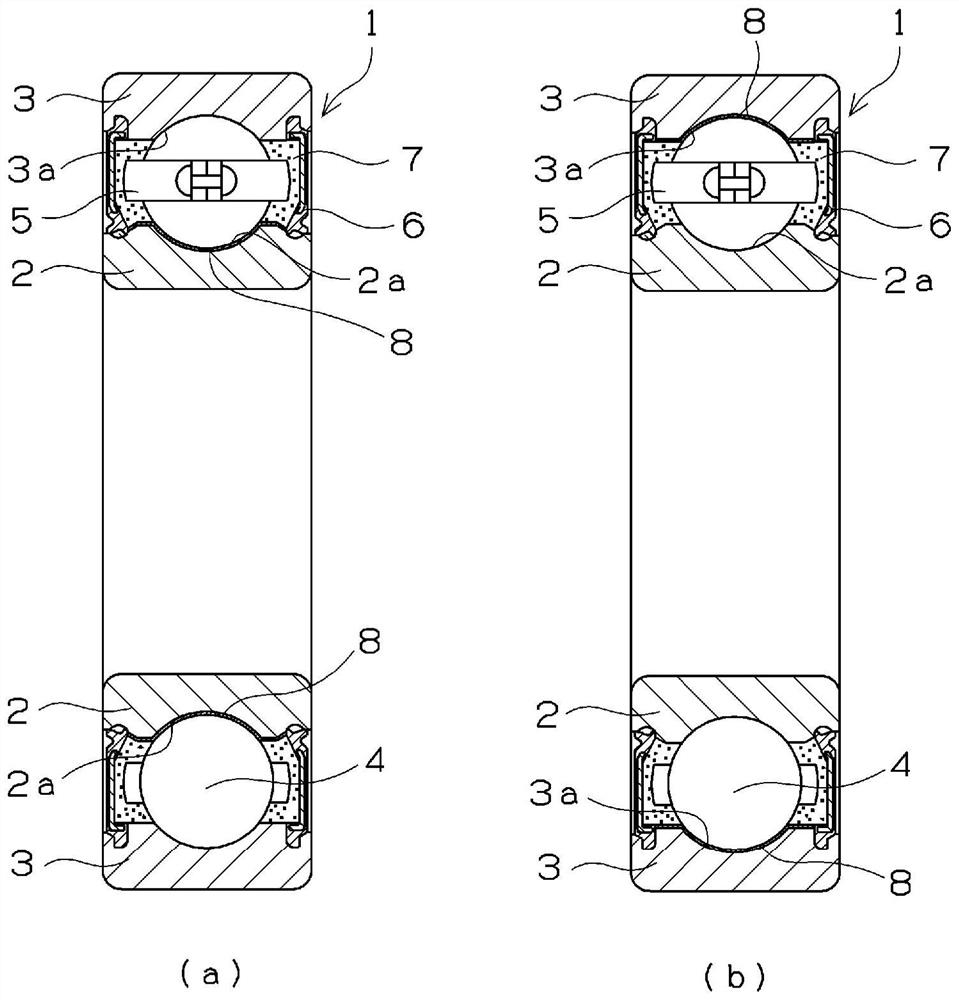

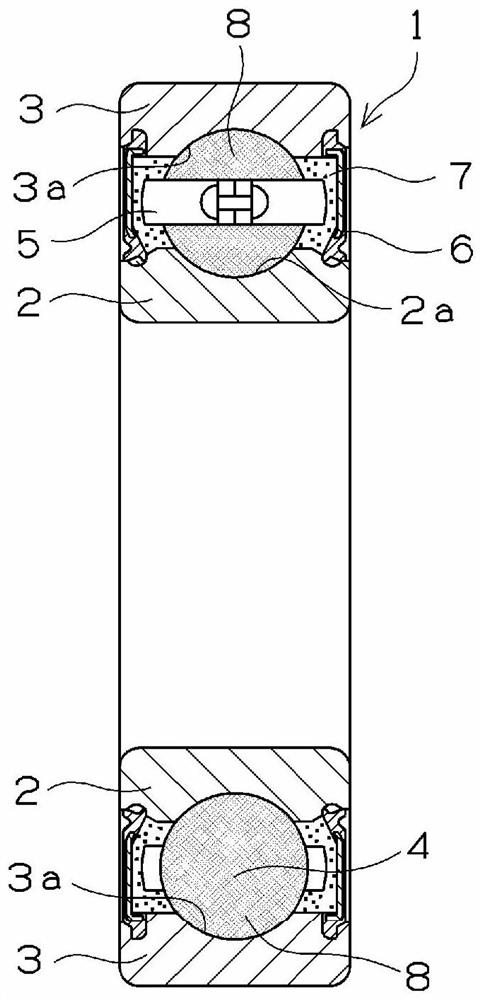

A technology for rolling bearings and rolling elements, which is applied in the field of rolling bearings, and can solve the problems of weak base material adhesion, small deformation ability, and damage to raceway surfaces, and achieve excellent peeling resistance, stress concentration reduction, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7、 comparative example 1~3

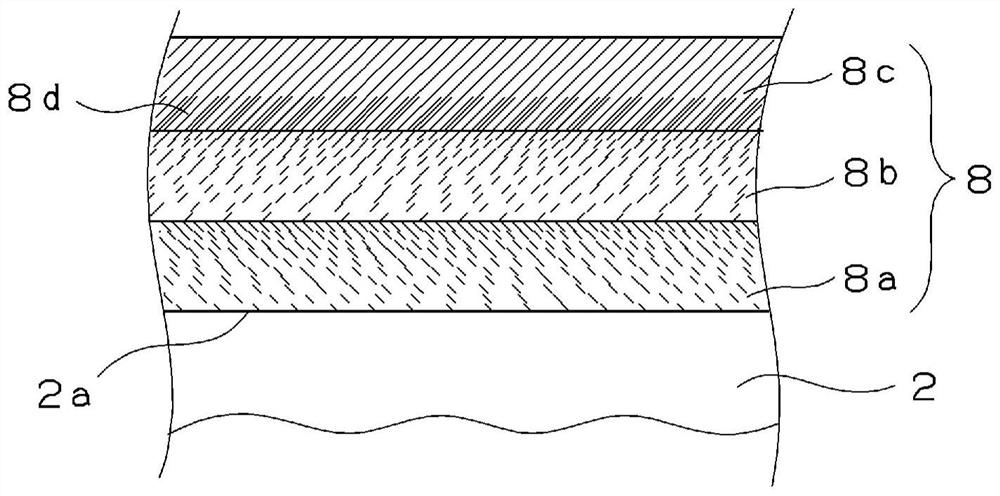

[0086] The substrates shown in Table 1 were ultrasonically cleaned with acetone and then dried. After drying, the substrate was installed in a UBMS device, and the base layer and the mixed layer were formed under the above-mentioned formation conditions. A DLC film was formed as a surface layer thereon to obtain a test piece having a hard film. The conditions for forming the surface layer are as follows: the degree of vacuum in the film-forming chamber in the above-mentioned device is 0.8 Pa, the bias voltage relative to the substrate is 50 V, and the ratio of the amount of methane gas introduced into the above-mentioned device to the Ar gas 100 (parts by volume) of the introduction amount is 1 (parts by volume). The results are also listed in Table 1. The film thicknesses in the table are the total film thicknesses of the three layers (base layer, mixed layer, and surface layer).

[0087]

[0088] For the obtained test pieces, use Figure 10 The 2-cylinder testing machi...

Embodiment 6

[0102] In Example 6, Ra and RΔq were at the same level as in Example 3, but the opponent aggressiveness was different. This is considered to be caused by the fact that Rsk becomes a positive value and the upward protrusion increases. In addition, from the results of Example 5, it is considered that it is not that the smaller the Rsk, the greater the wear of the opponent components, but that the value of Rsk not greater than 0 is important for the suppression of the opponent's aggressiveness.

[0103] Based on the above, in the present invention, in order to alleviate the stress concentration of the protrusion when the hard film is in contact with the counterpart, and to suppress the wear of the counterpart, the arithmetic mean roughness Ra and the root mean square slope RΔq of the roughness curve are used to The state of the substrate surface is defined.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| root mean square slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com