Ridge-culture minimum-tillage combined operation machine for fertilizing, sowing and corn stalk field-returning

A combined operation machine and corn stalk technology, applied in the field of agricultural machinery, can solve the problems of poor soil fertility, easy occurrence of diseases and insect pests, and difficult to rot of straw, so as to achieve good seedbed conditions, good soil fertility effect, and short maturity time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

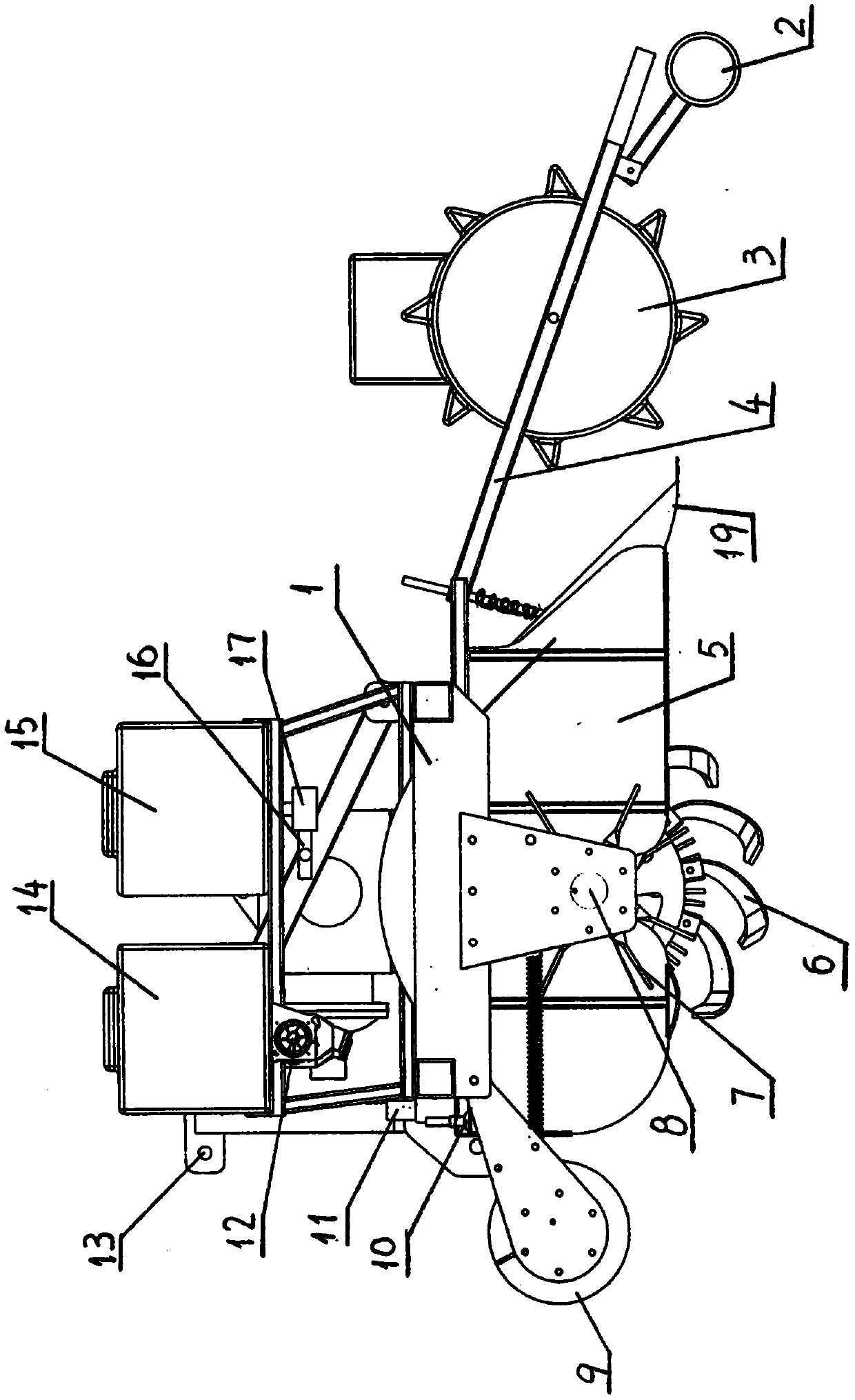

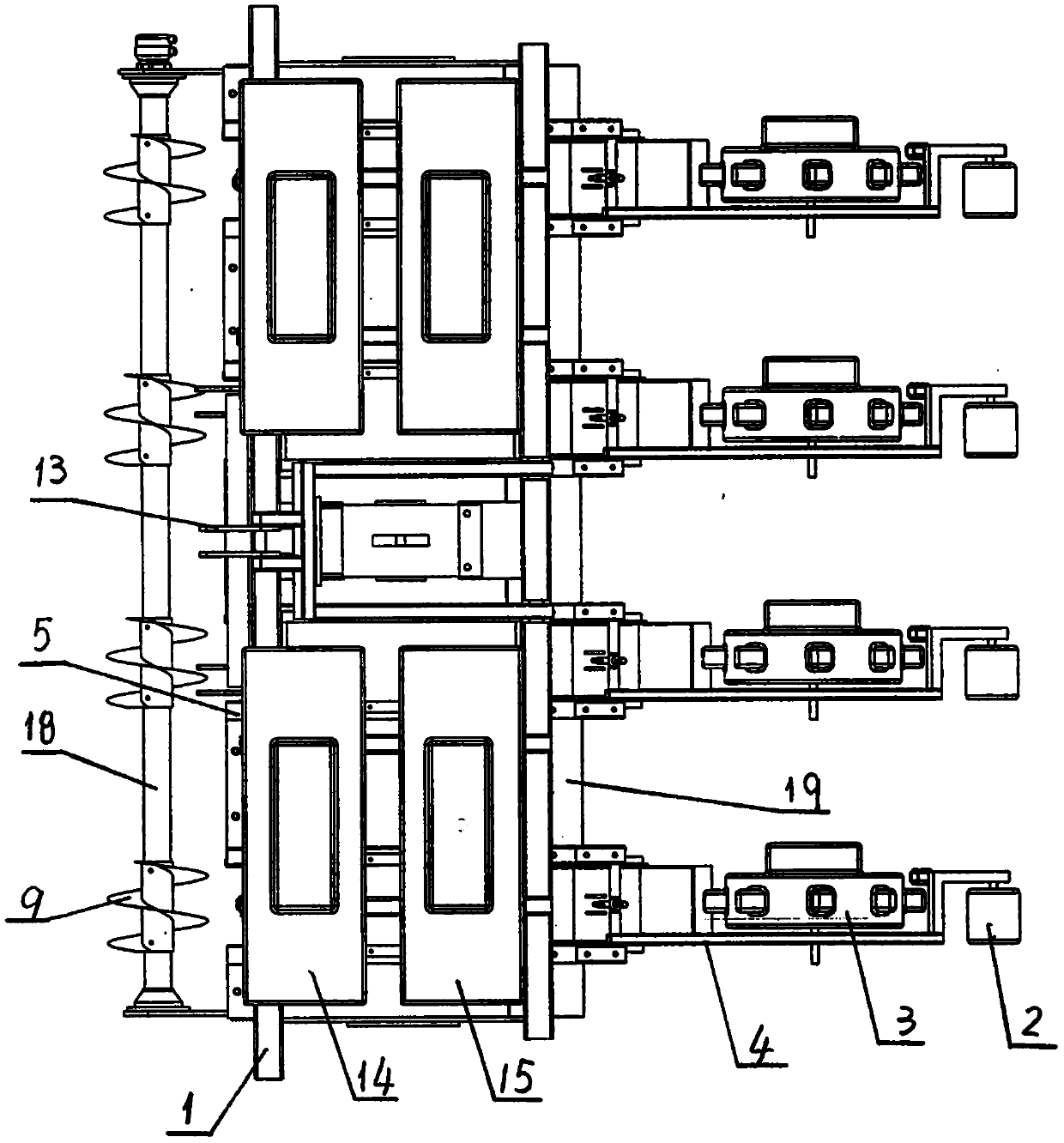

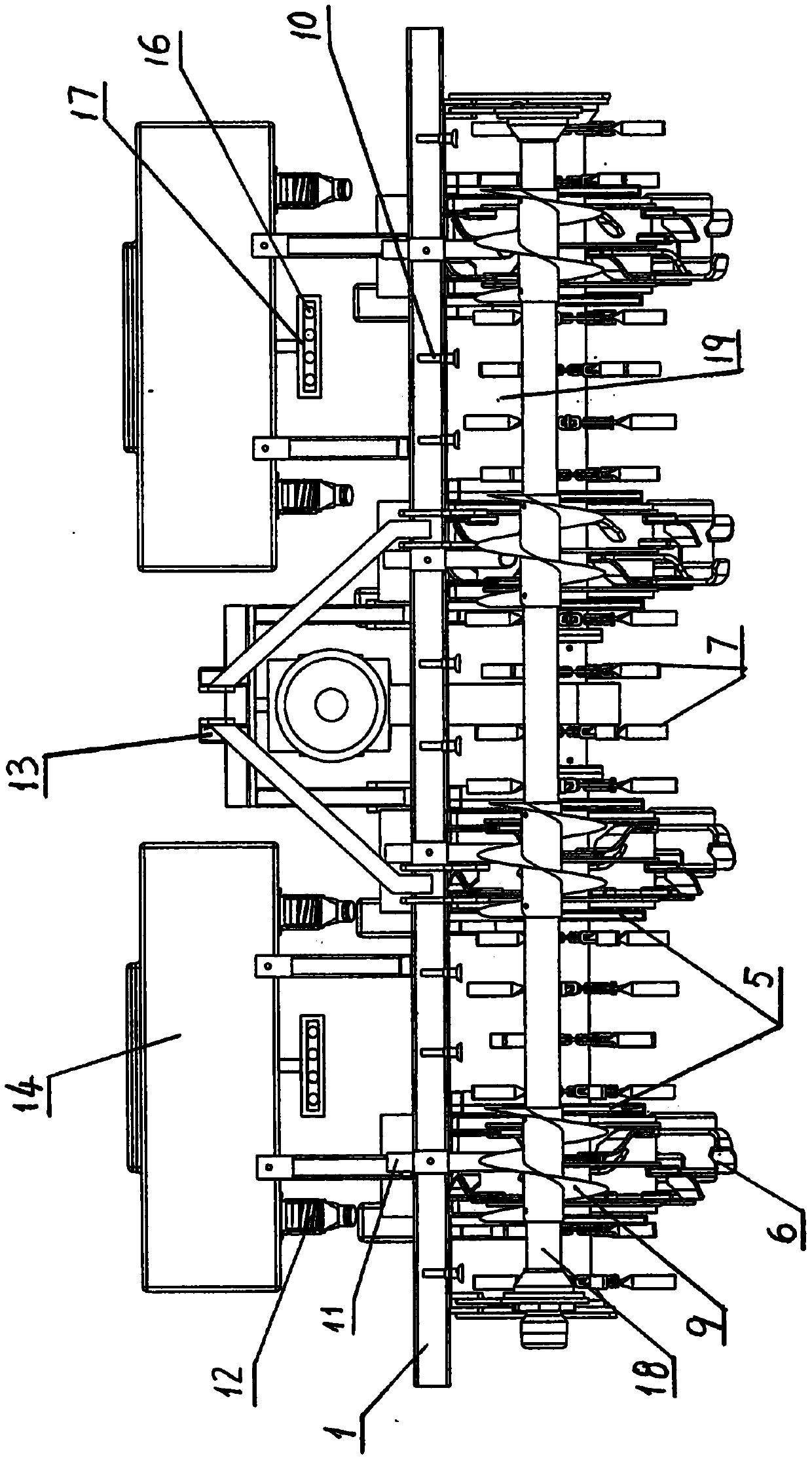

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A combined operation machine for ridge farming, less tillage, fertilization, sowing, corn stalks and returning to the field includes a frame assembly 1 and a three-point suspension assembly 13 mounted on the front part of the frame assembly 1, and on the upper part of the frame assembly 1 The fertilizer box 14 with the fertilizer discharger 12 and the liquid decomposing agent box 15 with the liquid pump 17 are fixed respectively; on the lower part of the frame assembly 1, parallel and rotatable ones are installed sequentially to move the straw The drive shaft 18 and the combined rotary tillage and mixing roller shaft 8; the helical blade 9 is fixed on the said stalk traversing drive shaft 18, which is located above the position of the ridge, and the rotary tillage and mixing combined roller shaft 8 The fixed rotary tiller group 6 and the mixing rod group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com