Preparation method of organic fertilizer

An organic fertilizer and organic waste technology, applied in the field of fertilizers, can solve the problems of large nitrogen volatilization loss and increased fermentation cost, and achieve the effects of reducing nitrogen volatilization, strong fertilizer retention, and rapid temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

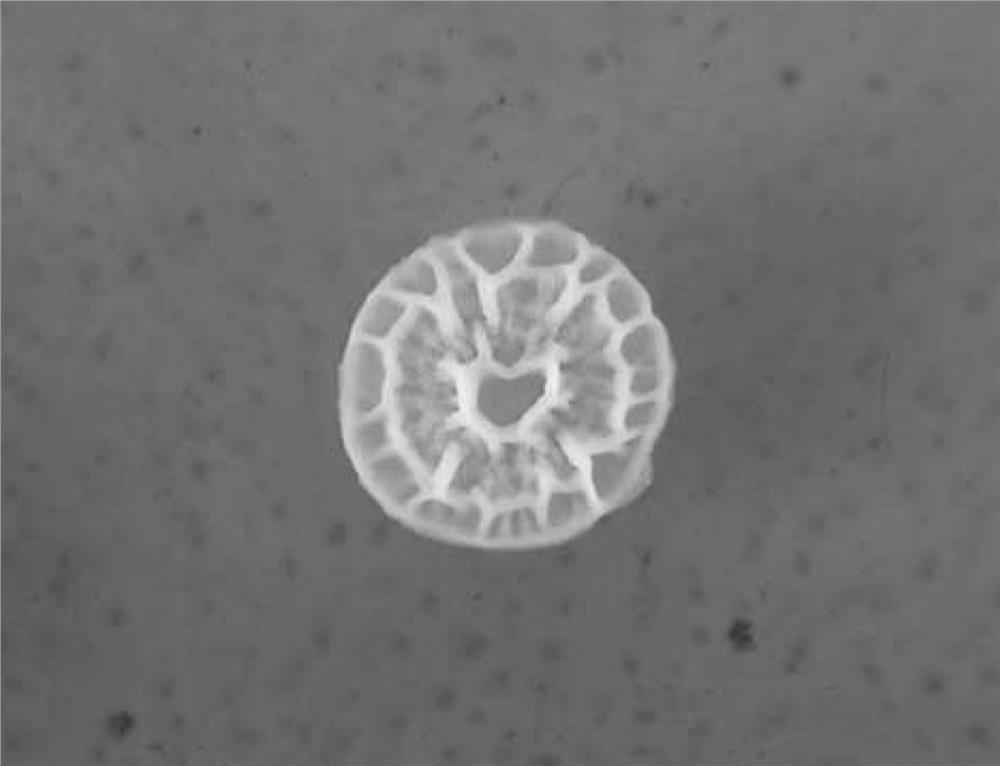

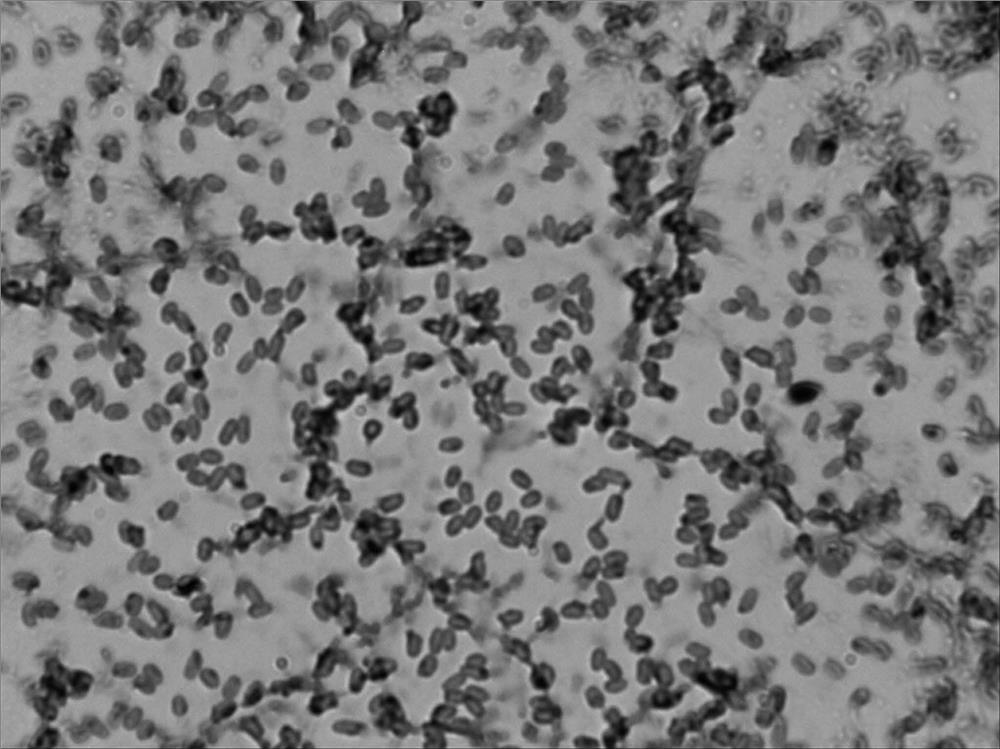

Image

Examples

Embodiment 1

[0050] The embodiment of the present invention provides a method for preparing an organic fertilizer. The preparation method includes: adjusting the water content after compounding sludge and rice husk at a ratio of 3:1, and adjusting the ratio according to the mass percentage of 65% water to obtain organic waste Mixture: Add the microbial composite fermentation agent to the organic waste mixture according to the mass ratio of the microbial composite fermentation agent to the organic waste mixture in a ratio of 1:10000, and use a turning and throwing device to fully mix After stacking, a mixed material heap is formed; the mixed material heap is not turned over and fermented for 15 days to prepare the organic fertilizer of Example 1. Wherein, the effective viable count content of the microbial composite fermentation inoculant is 5.0×10 8 cfu / mL, mainly composed of a concentration of 5.5×10 8 cfu / mL of liquid facultative bacillus and a concentration of 0.5 x 10 8 The cfu / mL li...

Embodiment 2

[0058] The embodiment of the present invention provides a method for preparing organic fertilizer. The preparation method includes: adjusting the water content after compounding pig manure and sawdust in a ratio of 3:1, and adjusting the ratio according to the mass percentage of 60% water to obtain a mixture of organic waste Material; according to the ratio of the mass ratio of the microbial composite fermentation agent to the organic waste mixture of 1:10000, add the microbial composite fermentation agent to the organic waste mixture, and use the turning and throwing equipment to fully mix Pile up to form a mixed material heap; the mixed material heap is not turned over and fermented for 18 days to prepare the organic fertilizer of Example 2. Wherein, the effective viable count content of the microbial composite fermentation inoculant is 5.9×10 8 cfu / mL, mainly composed of a concentration of 6.5×10 8 cfu / mL of liquid facultative bacillus and a concentration of 0.5 x 10 8 Th...

Embodiment 3

[0066] The embodiment of the present invention provides a method for preparing organic fertilizer. The preparation method includes: adjusting the water content after compounding sheep manure and mushroom dregs according to the ratio of 3:1, and adjusting the proportion according to the mass percentage of 56% water to obtain organic waste Mixture: Add the microbial composite fermentation agent to the organic waste mixture according to the ratio of the mass ratio of the microbial composite fermentation agent to the organic waste mixture of 1:11000, and use the turning and throwing equipment to fully mix After stacking, a mixed material heap is formed; the mixed material heap is not turned over and fermented for 12 days to prepare the organic fertilizer of Example 3. Wherein, the effective viable count content of the microbial composite fermentation inoculant is 7.25×10 8 cfu / mL, mainly composed of a concentration of 8.0×10 8 cfu / mL of liquid facultative bacillus and a concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com