Filtering treatment system for printing and dyeing sludge and operation method thereof

A technology for printing and dyeing sludge and treatment system, which is applied in the field of flue gas purification and can solve problems such as affecting the effect of flue gas purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

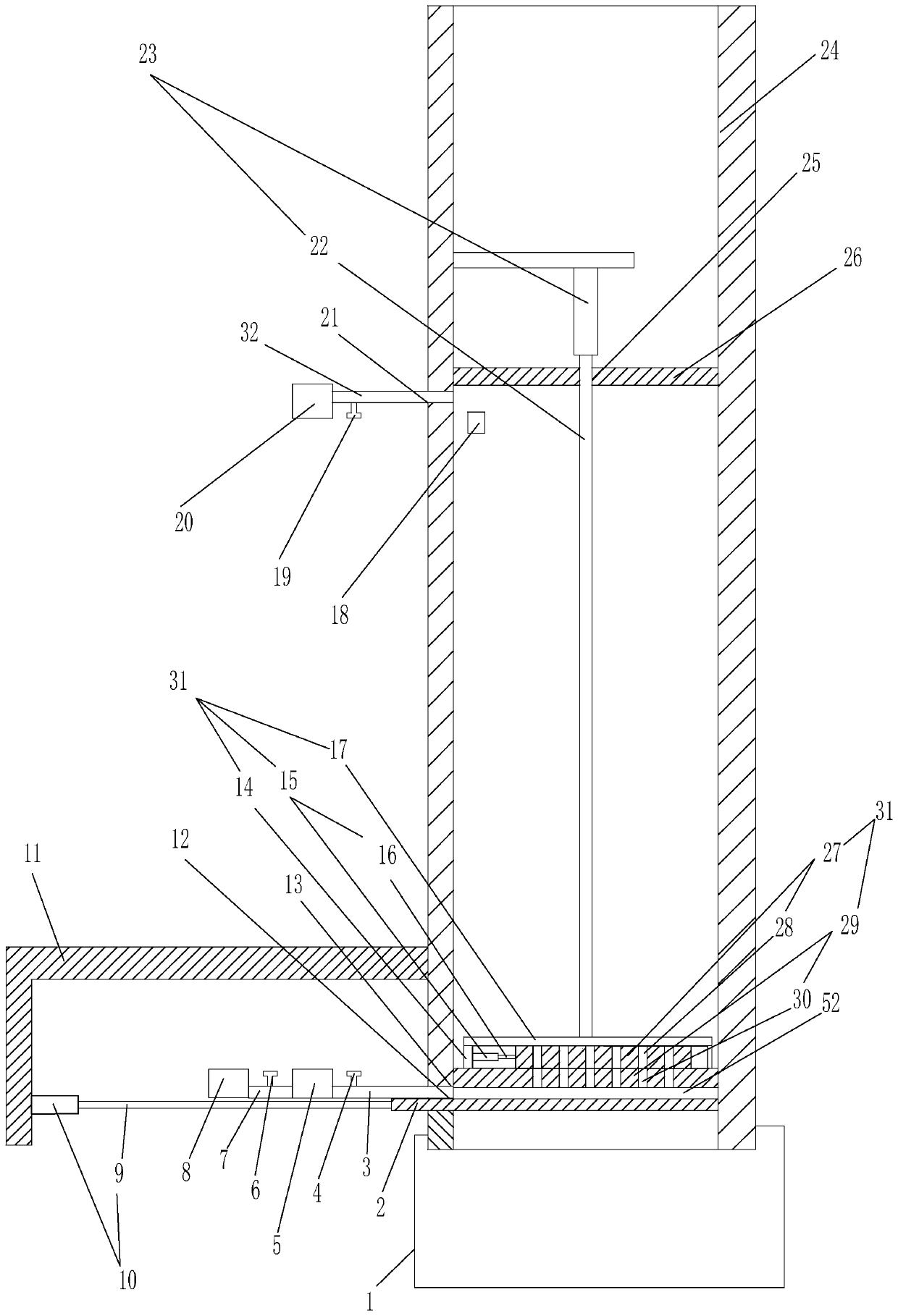

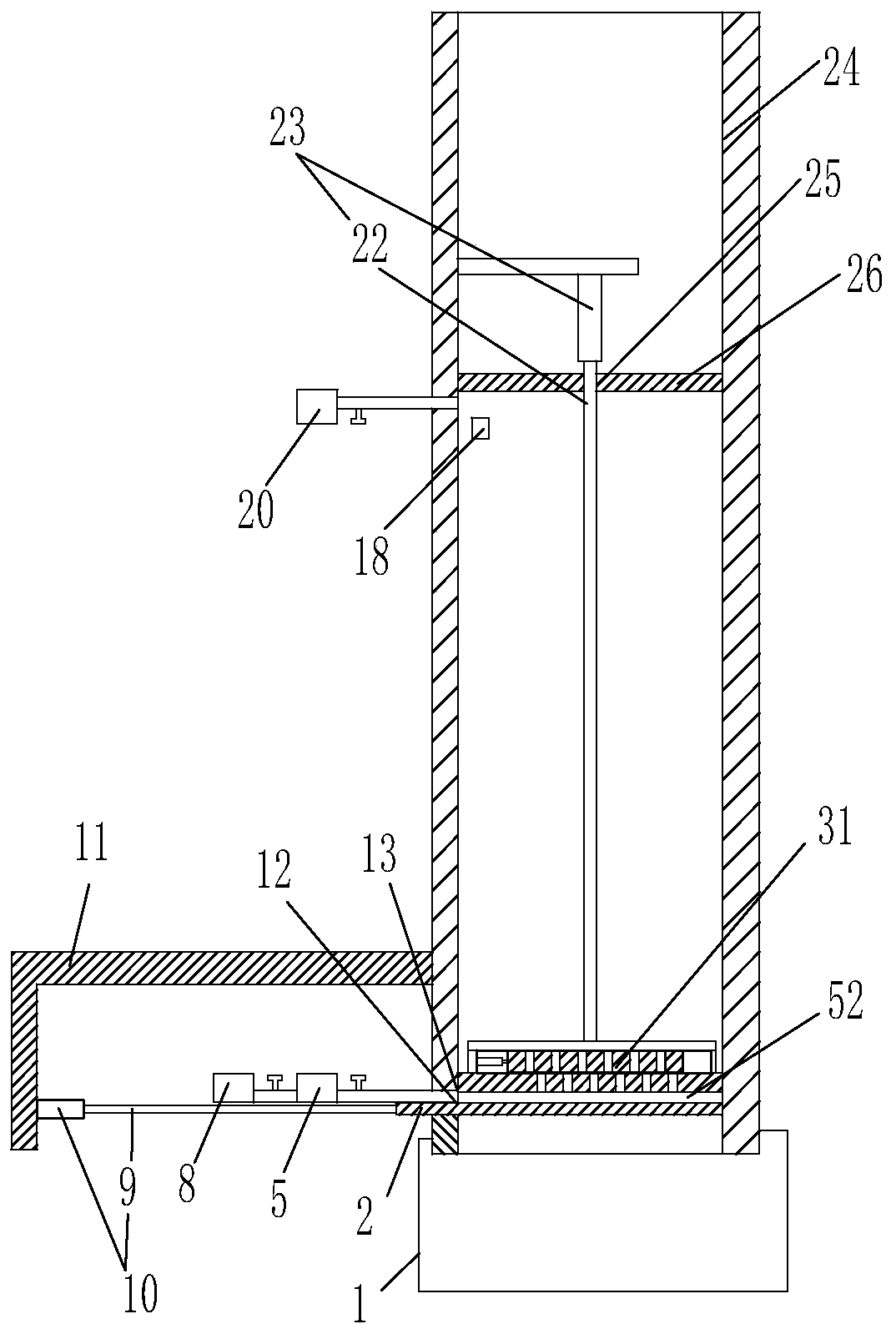

[0091] Embodiment 1, is used for the filter treatment system of printing and dyeing sludge, see figure 1 , Figure 23 shown. Comprising a boiler 8 capable of burning printing and dyeing sludge and a flue gas purification device 20, and also including a No. 1 vertical pipe 24 with a rectangular cross-section of the inner lumen, a smoke extractor 5, a storage device 33 and a controller 34; A left bracket 11 is provided on the left side outer tube wall of the tube, and a No. 1 cylinder 10 with a telescopic rod arranged to the right is arranged on the left bracket;

[0092] The lower end of the left pipe wall of the No. 1 vertical pipe is provided with a No. 1 flue gas inlet 13 communicating with the lumen of the No. 1 vertical pipe; The two ends are butt-connected to the flue gas inlet of the hood and the flue gas outlet of the boiler respectively, and the two ends of a No. 2 flue gas communication pipe 3 with No. 2 valve 4 are butt-connected to the flue gas outlet of the hood ...

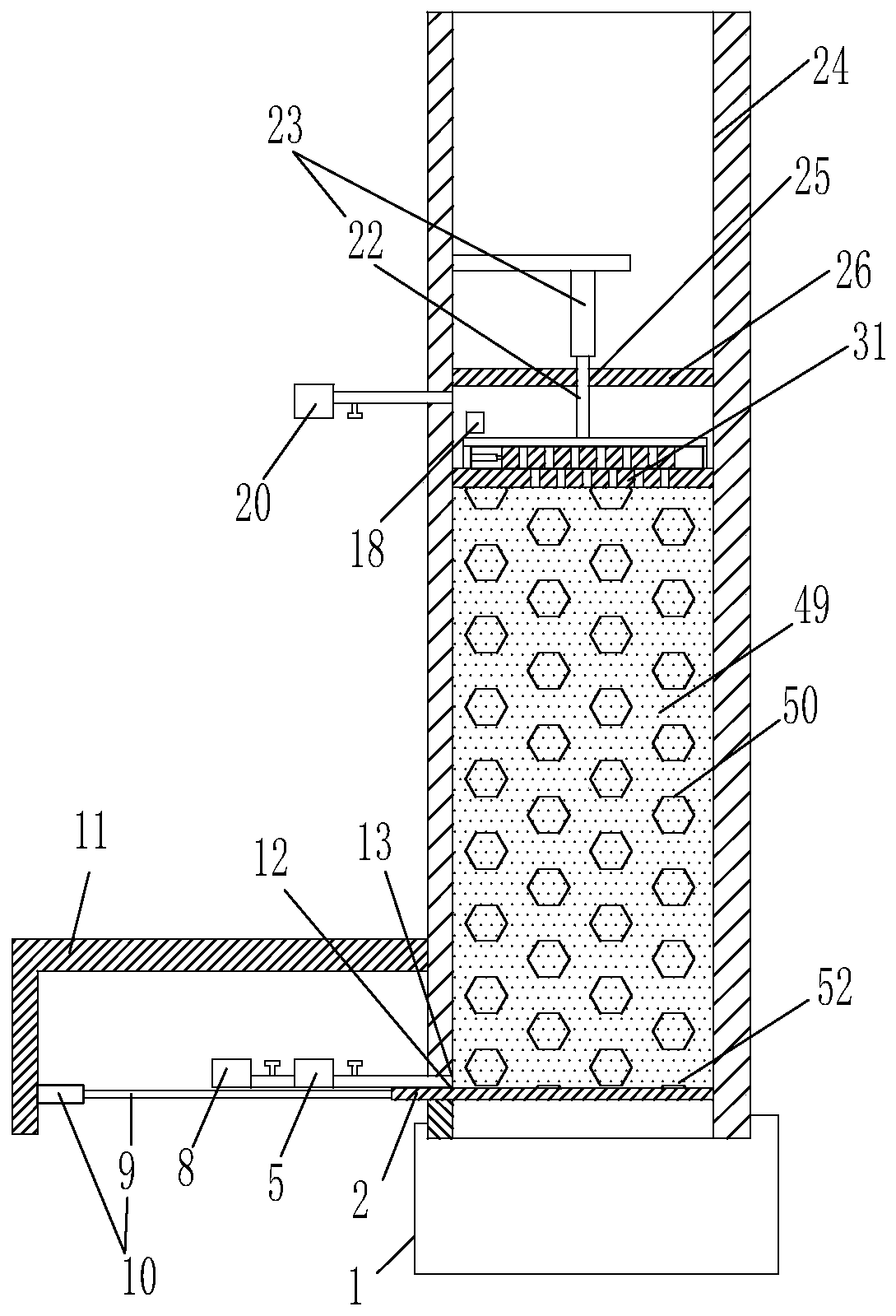

Embodiment 2

[0139] Embodiment 2, the difference between embodiment 2 and embodiment 1 are as follows:

[0140] A No. 1 groove 36 is provided on the left inner wall of the No. 1 vertical pipe located below the limit block and above the No. 1 flue gas inlet hole, and a No. 1 lamp 37 is arranged in the No. 1 groove. In the notch of the No. 1 groove on the outside side, the No. 1 light-transmitting glass sheet 38 whose outer surface and the left inner wall surface of the No. 1 vertical tube are in the same vertical plane is sealed; The wall is provided with a No. 2 groove 41, and the No. 1 groove and the No. 2 groove are horizontally opposite to each other; the No. 1 photoelectric sensor 42 is arranged in the No. 2 groove, and the No. The notch of the groove is airtightly provided with the No. 2 light-transmitting glass sheet 43 whose outer surface is in the same vertical plane as the left inner wall surface of the No. 1 vertical pipe; Both the groove and the No. 2 groove are located below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com