Grinding and milling drill with drill tip capable of breaking chips

A drill tip and chip breaking technology, which is applied in drilling/drilling equipment, drill repairing, twist drills, etc., can solve problems such as large changes in the rake angle, difficult flow of cutting fluid, and large speed differences. Good chips, reduced cutting torque, and increased feed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

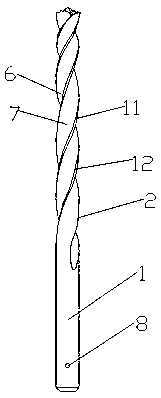

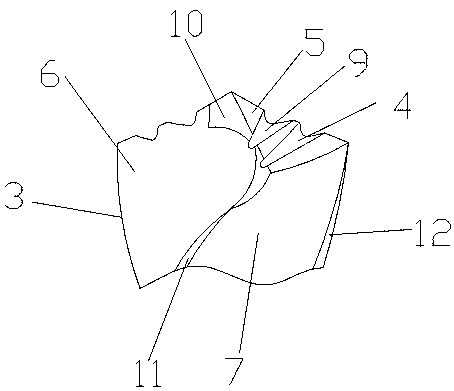

[0017] As shown in the figure, this embodiment provides a drill tip chip breaking milling drill, which includes a drill shank 1 and a twist-shaped cutter body 2, the drill shank 1 is a straight shank, and the top end of the cutter body 2 is a drill tip 3, The drill tip 3 is provided with two main cutting edges 4 and two symmetrical flanks 5, the outer wall of the cutter body 2 is provided with a helical spiral groove 6 and a back 7, the drill shank 1 A plurality of positioning holes 8 are uniformly arranged along the outer periphery, and the drill tip 3 is provided with two chip dividing grooves 9 around the flank 5, and the two rear flute edges of the drill tip 3 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com