Highly rigid composite resin composition with excellent tactility and heat resistance and article molded therefrom

A technology of composite resin and composition, which is applied in the field of high-rigidity composite resin composition, can solve problems such as weak price competitiveness, adhesiveness between molded products and fabrics, etc., and achieve excellent touch and heat resistance, excellent rigidity and durability scratchy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] According to a method for preparing a composite resin composition according to another embodiment of the present invention, based on 100 parts by weight of the following components (a) to (f), the method includes the following steps: (A) mixing 10 to 40 parts by weight of propylene Polymer resin (a), the glass long fiber (b) of 25 to 60 parts by weight, the modified polyolefin resin (c) of 0.1 to 10 parts by weight are mixed to prepare the step of first masterbatch; (B) 1 15 parts by weight of polypropylene resin (d) selected from ethylene-propylene block copolymer resins and ethylene-propylene random copolymer resins, 30 to 50 parts by weight of ethylene-α-olefin rubber copolymer resin (e ), 0.1 to 10 parts by weight of polyamide resin (f), 0.1 to 5 parts by weight of modified polyolefin resin (c), and 500 to 3,000 ppm of nucleating agent (g) are mixed to prepare a second masterbatch step; and (c) a step of mixing the first masterbatch and the second masterbatch; where...

Embodiment

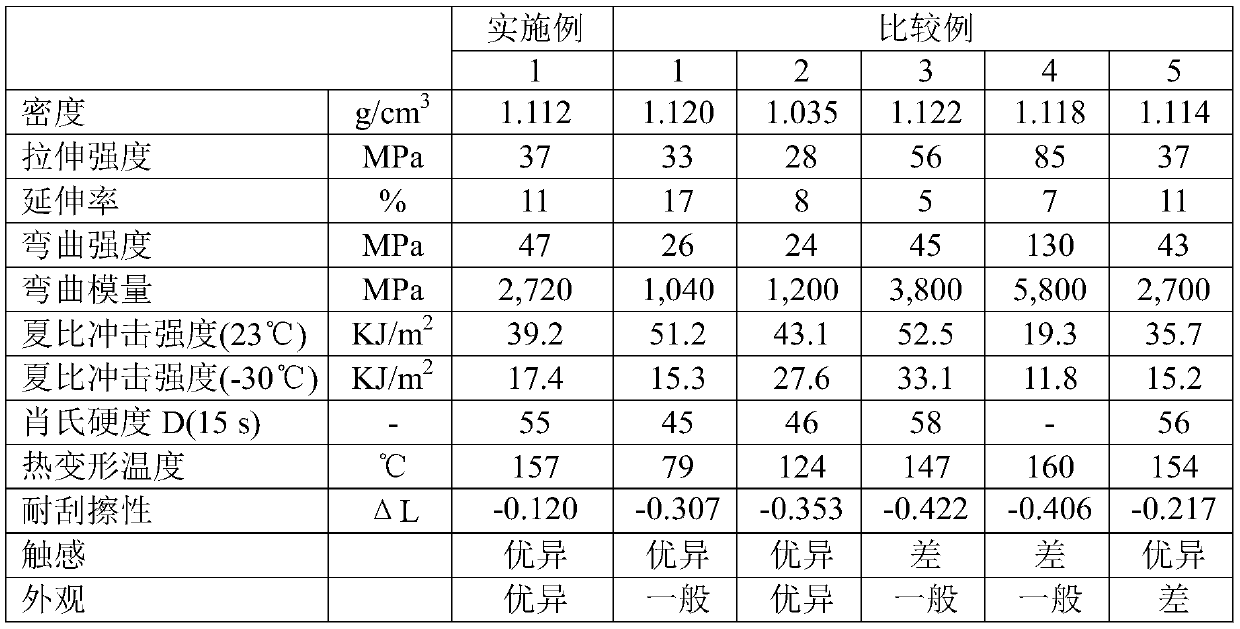

[0058] Hereinafter, the present invention will be described in more detail through examples and comparative examples. However, the following examples are only for illustrating the present invention, and the scope of the present invention is not limited thereto.

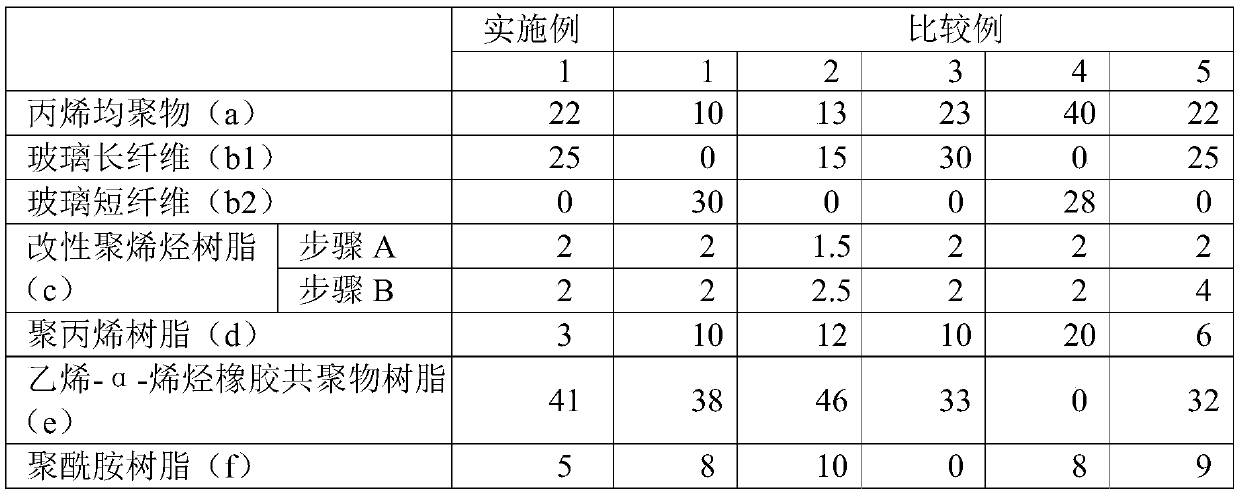

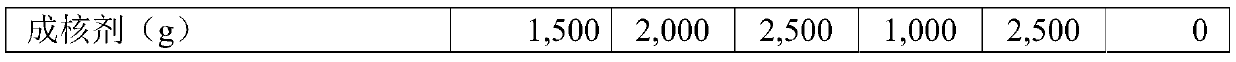

[0059] The contents of the following resins and compounds used in Examples and Comparative Examples are shown in Table 1 (unit: parts by weight, unit of nucleating agent is ppm).

[0060] Resin (a): a resin obtained by mixing two kinds of propylene homopolymers having a melt index of 30 and 1,000 when measured at 230° C. under a load of 2.16 kg at a weight ratio of 6:4.

[0061] Glass fiber (b1): long glass fiber with an average diameter of 15 μm and an average length of 12 mm.

[0062] Glass fiber (b2): Short glass fibers with an average diameter of 15 μm and an average length of 1 mm.

[0063] Resin (c): polypropylene resin grafted with 1% by weight of maleic anhydride.

[0064] Resin (d): An ethylene-propylene b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com