Municipal road sewer pipeline construction device and method

A technology for construction of municipal roads and pipelines, applied in sewer systems, waterway systems, water supply devices, etc., can solve problems such as pipeline pressure increase and pipeline damage, and achieve the effect of ensuring stability and ensuring location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

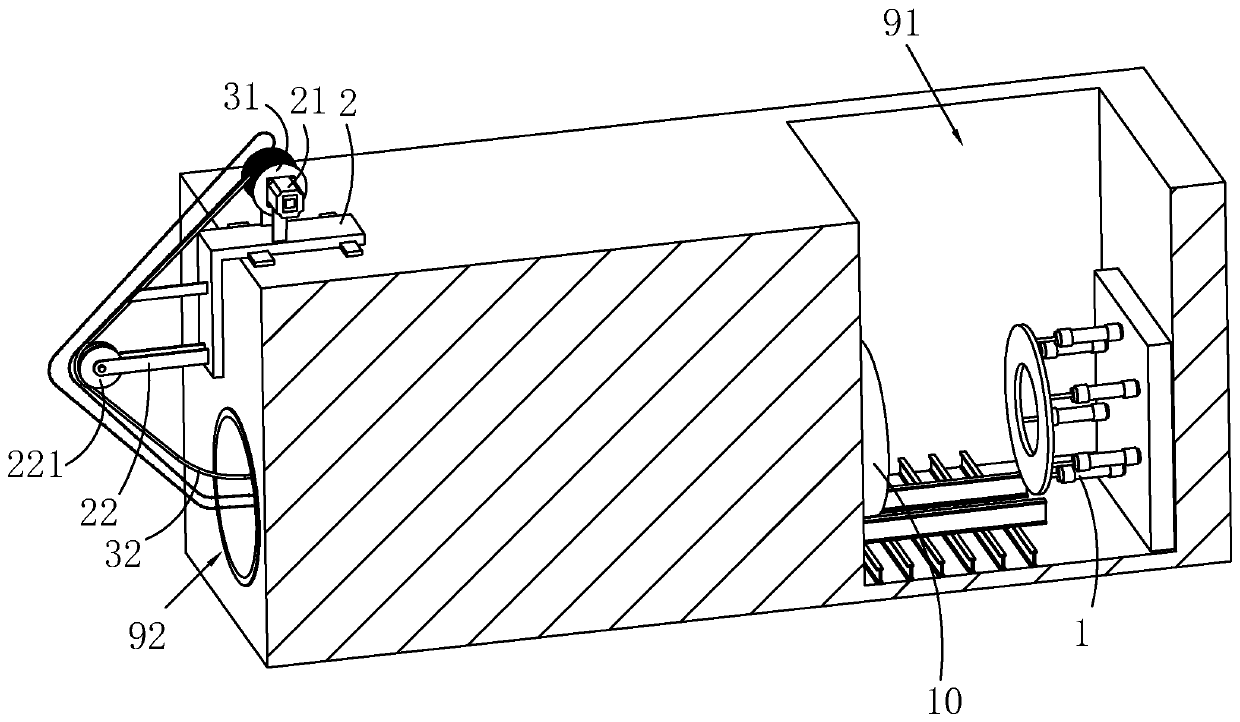

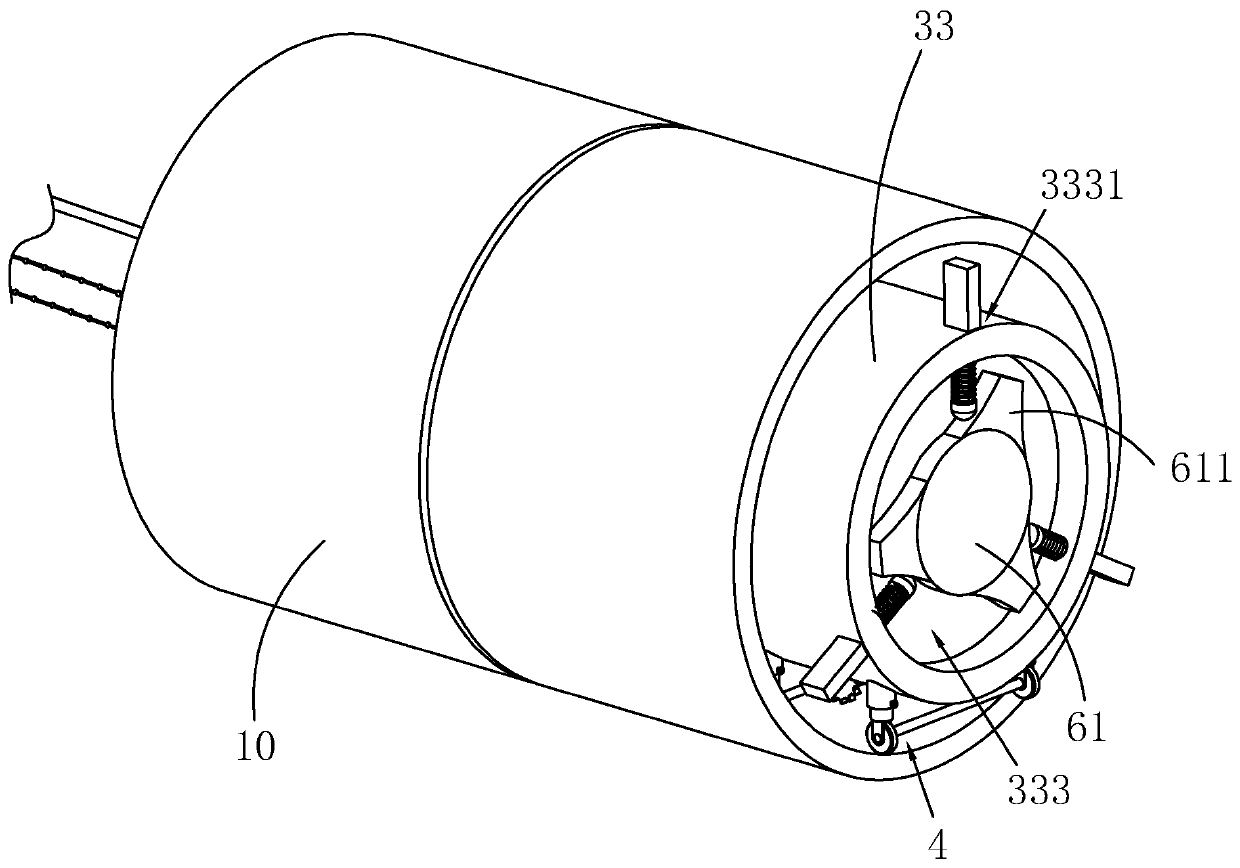

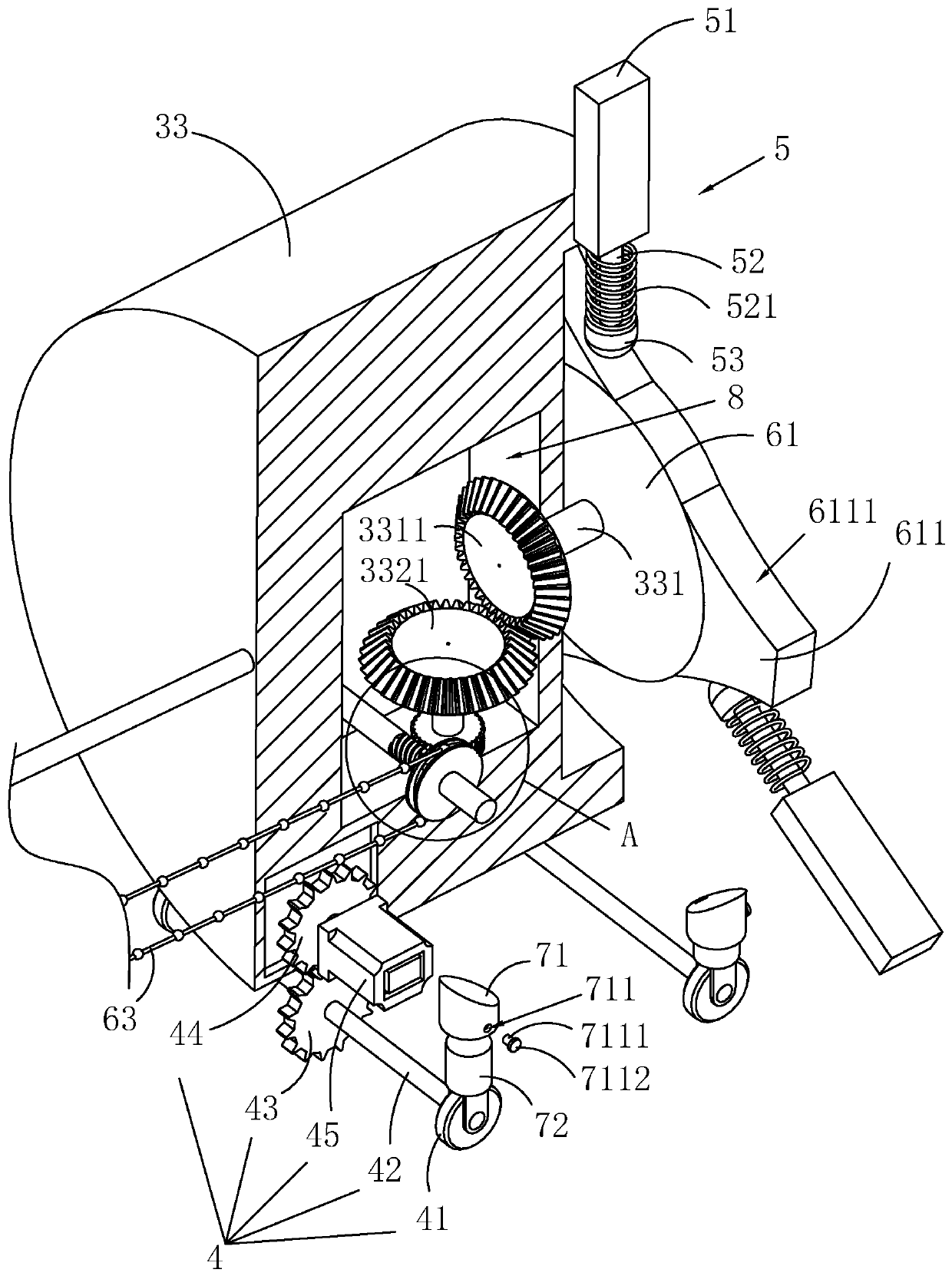

[0047] like figure 1 , 2 As shown, a municipal road sewer pipeline construction equipment includes a hydraulic cylinder 1 for pushing the pipeline 10 into the foundation hole 92 , and the hydraulic cylinder 1 is arranged at the bottom of the working well 91 . It also includes a frame 2 on which a traction mechanism is arranged; the traction mechanism includes a winding wheel 31 , a stay rope 32 and a working head 33 . The reel 31 is rotated and arranged on the frame 2, and the frame 2 is provided with a driving source 21 for driving the reel 31 to rotate; Wire wheel 31 is coaxially fixedly connected.

[0048] like figure 1 , 2 As shown, an extension rod 22 is fixedly arranged on the frame 2 , and a guide wheel 221 for guiding the pull cord 32 is rotatably arranged on the extension rod 22 . The frame 2 is arranged at one end away from the working well 91 , and the guide wheel 221 is located obliquely above the foundation hole 92 . One end of the stay rope 32 is wound on t...

Embodiment 2

[0070] A construction method for municipal road sewer pipeline 10, comprising the following steps:

[0071] S1, excavating the working well 91;

[0072] S2. Excavating the foundation hole 92 for the pipeline 10 through the earth pressure balance pipe jacking machine;

[0073] S3, install the hydraulic cylinder 1 and the laying track at the bottom of the working well 91, and install the municipal road sewer pipeline 10 construction equipment at the foundation hole 92 at one end of the working well 91;

[0074] S4. Lift the pipeline 10 to the track under the working well 91, and push the pipeline 10 into the foundation hole 92 through the hydraulic cylinder 1;

[0075] S5. Lower the working head 33 from the end of the base hole 92 away from the working well 91 into the base hole 92, and then drive the working head 33 to move to the end close to the working well 91 through the traveling mechanism 4, and continue to move to the base hole 92 When the pipe 10 is jacked in, drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com