Vehicle suspension structure with high safety

A safety and vehicle technology, applied in elastic suspensions, vehicle parts, cantilevers mounted on pivots, etc., can solve problems such as poor versatility, high replacement costs, inconvenient parts replacement, etc., to achieve easy replacement and high safety , good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

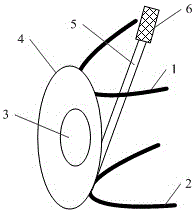

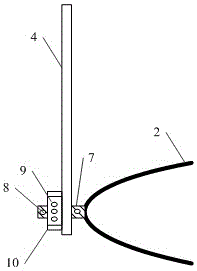

[0024] In the first embodiment, a vehicle suspension structure with higher safety is provided, please refer to Figure 1-Figure 2 , The structure includes:

[0025] Upper wishbone 1, lower wishbone 2, wheel bearing 3, shock-absorbing strut, connecting plate 4, clamp 10; the wheel bearing is connected to the connecting plate, the upper wishbone, the lower wishbone, and the shock-absorbing strut A connecting end 7 is provided on the upper side, the outer surface of the connecting end is threaded, the upper side of the connecting plate is provided with a screw hole, the lower end of the connecting plate is provided with two screw holes, and the connecting end of the upper fork arm Inserted into the upper end screw hole of the connecting plate, the connecting end of the lower fork arm and the shock-absorbing strut is inserted into the two screw holes at the lower end of the connecting plate; the connecting end is provided with a nut 9 for mating and fixing, Both the connecting end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com