Filling body transverse deformation on-line monitoring system based on fiber bragg grating sensing

A technology of fiber grating and lateral deformation, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems such as the inability to realize filling body monitoring, achieve good monitoring effect, improve monitoring accuracy, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

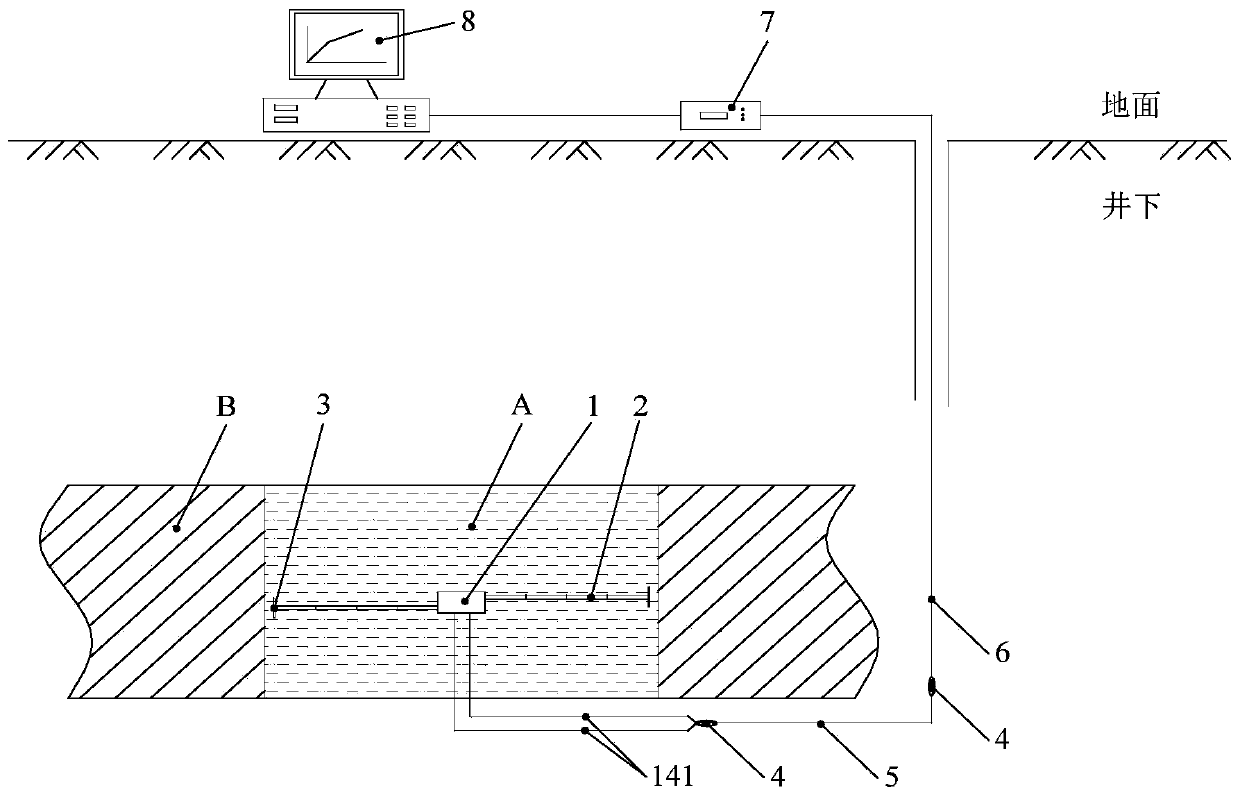

[0051] An on-line monitoring system for lateral deformation of a filling body based on fiber Bragg grating sensing, including a bidirectional displacement measuring device based on fiber Bragg grating sensing, a fixed disk, a coupler, an optical fiber, a mine optical cable, a fiber grating demodulator, and a computer system.

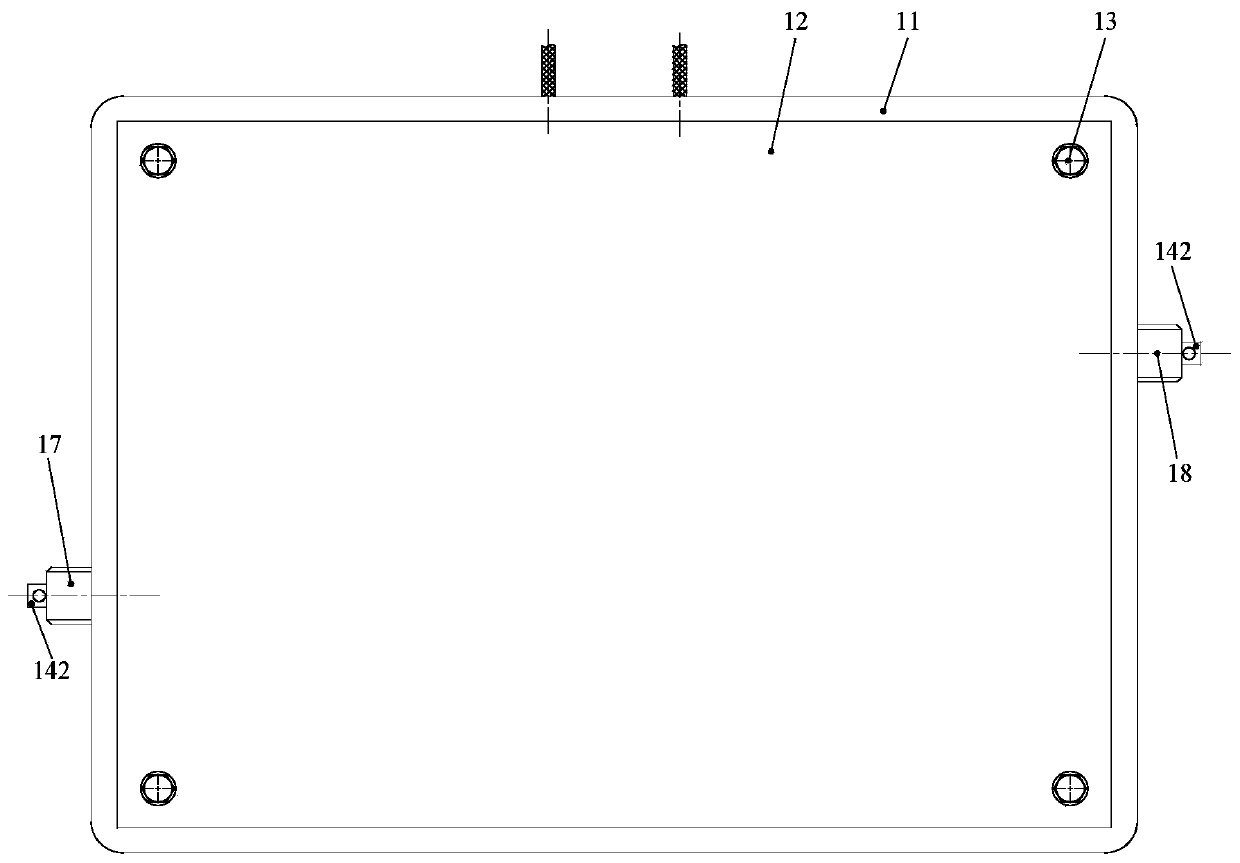

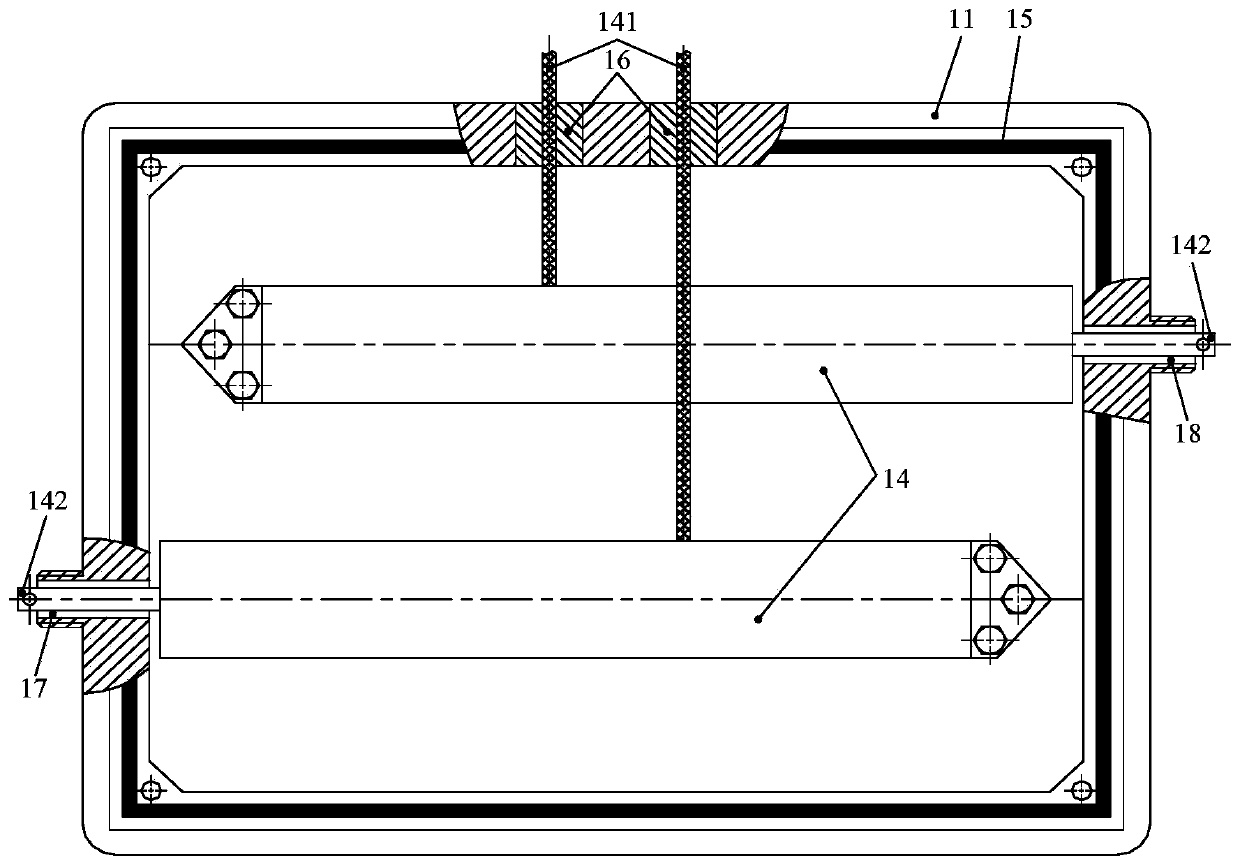

[0052] The bidirectional displacement measurement device based on fiber grating sensing includes a housing, an upper cover, a steel pipe, an extension line and two fiber grating displacement sensors; the housing is a hollow cuboid structure without a cover, and a sealing ring is provided at the upper opening;

[0053] The optical fiber grating displacement sensor is preferably a rod-type optical fiber grating sensor, and the optical fiber grating displacement sensor is fixedly connected to the housing; the housing and the upper cover are connected by bolts; the housing and the upper cover are preferably made of high-strength fine steel.

[0054] There is ...

Embodiment 2

[0065] to combine Image 6 As shown, the installation and monitoring method of the online monitoring system for lateral deformation of the filling body based on fiber Bragg grating sensing in Embodiment 1 is as follows:

[0066] The first step, according to the specific measurement purpose, intercept the extension line of appropriate length, and select a certain number of steel pipes, connect the shell with the steel pipe, extension line and fixed plate, and connect the connected two-way sensor based on fiber grating sensor The displacement measuring device is installed in a suitable position;

[0067] The second step is to connect the optical fiber connectors of each arranged bidirectional displacement measurement device based on fiber grating sensing to the optical fiber through the coupler, connect the optical fiber to the mine optical cable through the coupler, and the mine optical cable to the fiber grating demodulator Connect, connect the fiber grating demodulator with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com