Train air brake antiskid device performance test method and test bed

A technology of air brake and anti-skid device, which is applied in the direction of railway vehicle testing, machine/structural component testing, mechanical component testing, etc. It can solve the problems of complex wheel-rail adhesion characteristics, low reliability, and low economy. Achieve the effect of saving test cost and cycle, optimizing control strategy, and ensuring authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

[0067] Refer below Figure 1-Figure 5 The embodiment of the method for testing the performance of the train air brake anti-skid device disclosed in the present application is described in detail.

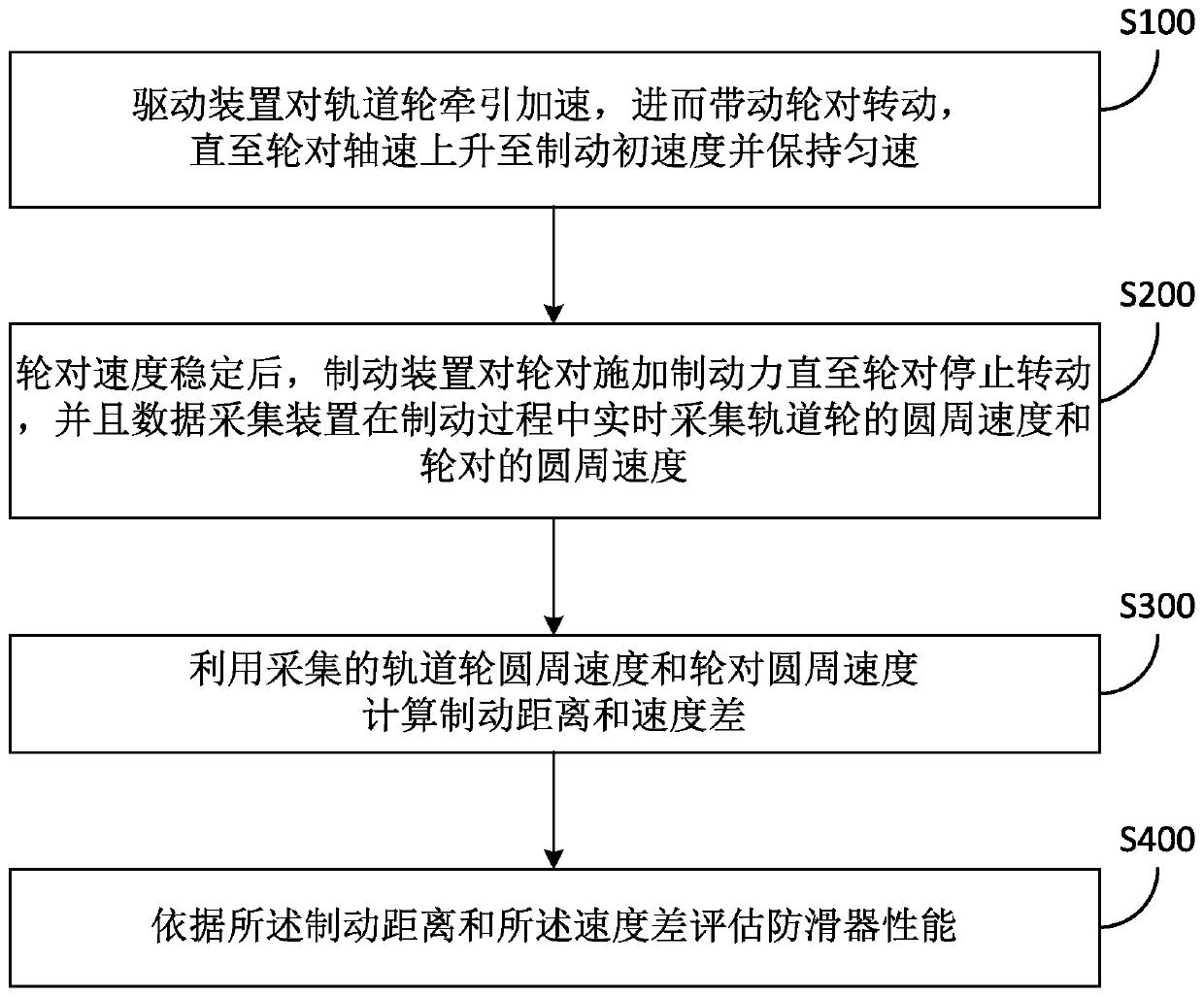

[0068] Such as figure 1 As shown, the anti-skid performance testing method disclosed in this embodiment comprises the steps:

[0069] In step 100, the driving device pulls and accelerates the track wheels, and then drives the wheelsets to rotate until the shaft speed of the wheelsets rises to the initial braking speed and maintains a constant speed.

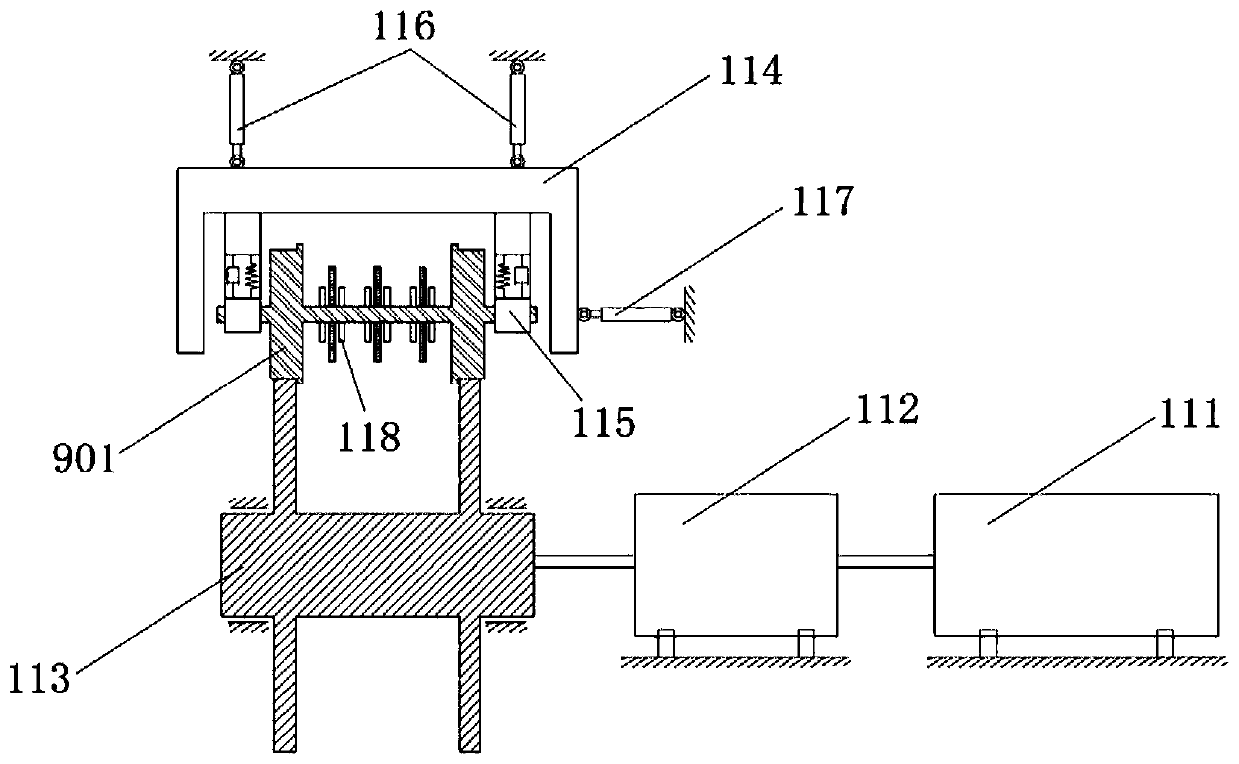

[0070] Such as figure 2 As shown, the driving device includes a track wheel motor 111, and the track wheel motor 111 and the track wheel 113 form a track wheel d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com