A method for quantifying the size of new shear cracks in mined rock mass

A technology of shear crack and quantification method, which is applied to the determination of geometric parameters of new cracks in rock body in rock engineering, rock mechanics theory and engineering application fields, and can solve problems such as engineering failure, delay in construction period, casualties and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

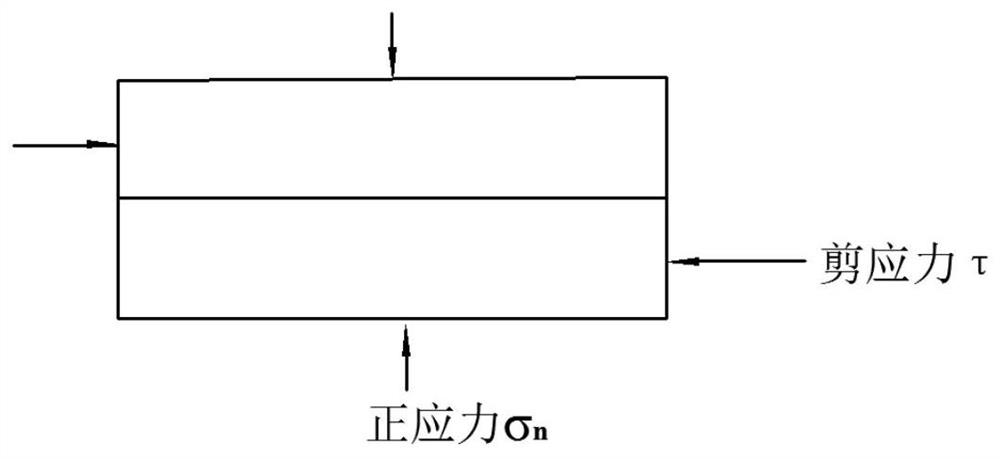

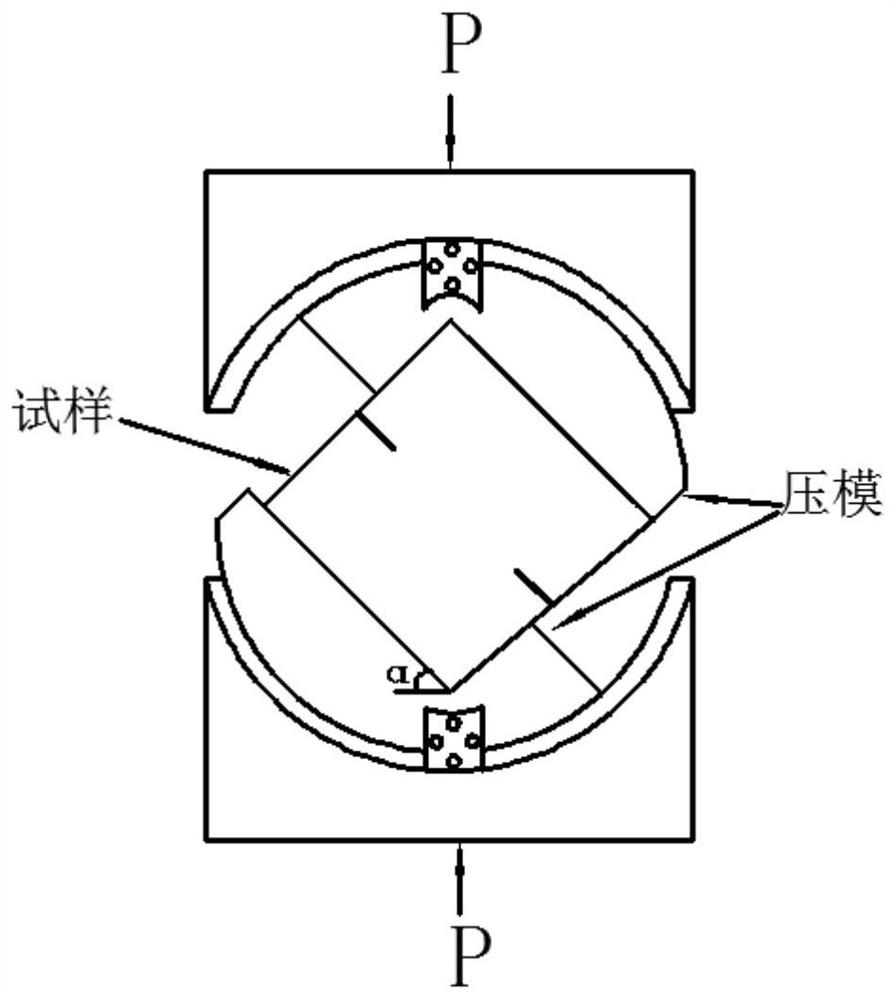

[0176] 1. Determine the physical and mechanical parameters of the rock through laboratory experiments. The results are shown in Table 1. The experimental methods for measuring the internal friction angle and shear fracture toughness are as follows: figure 1 , 2 shown.

[0177] Table 1

[0178]

[0179] 2. Install the microseismic monitoring system on the project site, and the coordinates of the sensors are shown in Table 2.

[0180] Table 2

[0181]

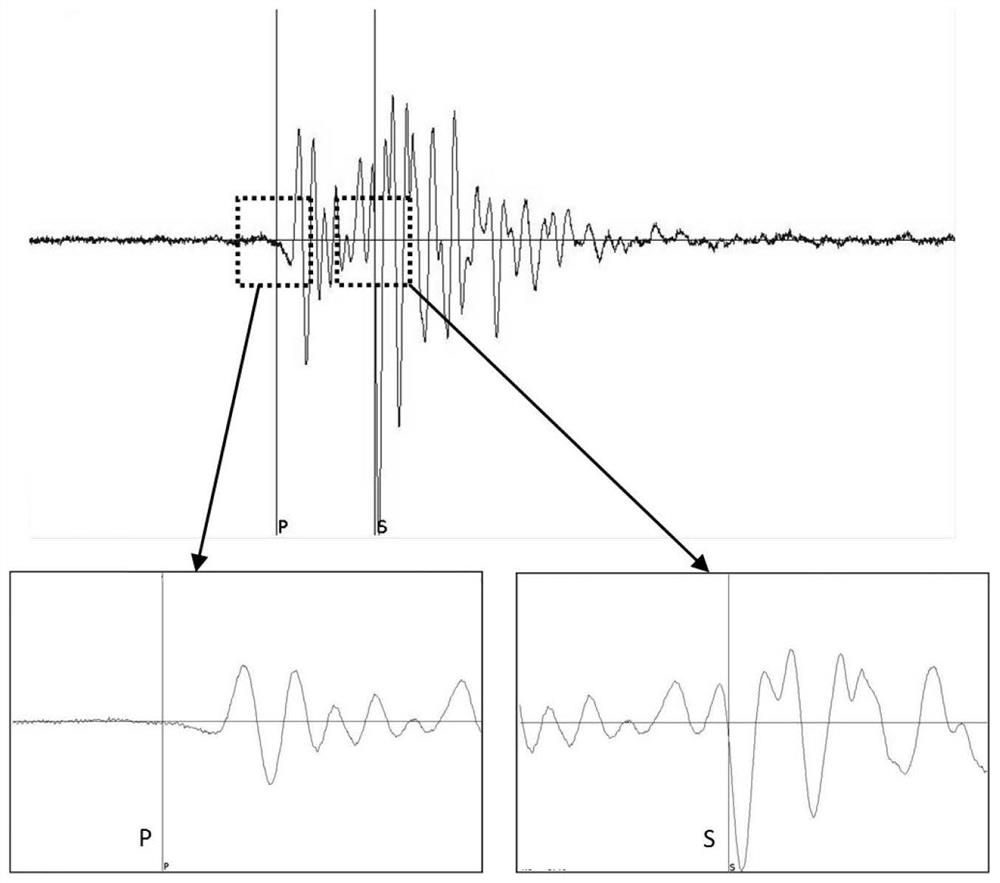

[0182] 3. Use the microseismic monitoring system to collect microseismic waves induced by rock mass rupture, and manually or automatically pick up the waveforms received by the microseismic sensors ( image 3 ), using the Geiger positioning algorithm to calculate the three-dimensional space coordinates of the rupture surface based on the arrival of the waveform, extract the initial amplitude of the waveform and perform moment tensor inversion, and then calculate the normal vector of the nodal plane, the three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com