A laser engraving method for the scale of the 3D glass cover of a watch

A 3D, watch cover technology, used in watches, clocks, instruments, etc., can solve the problems of unclear ink scale and easy falling off, and achieve the effect of marking accuracy, good aesthetics, and avoiding burrs and edge chipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further specifically described below through specific embodiments and accompanying drawings, but the present invention is not limited to these embodiments.

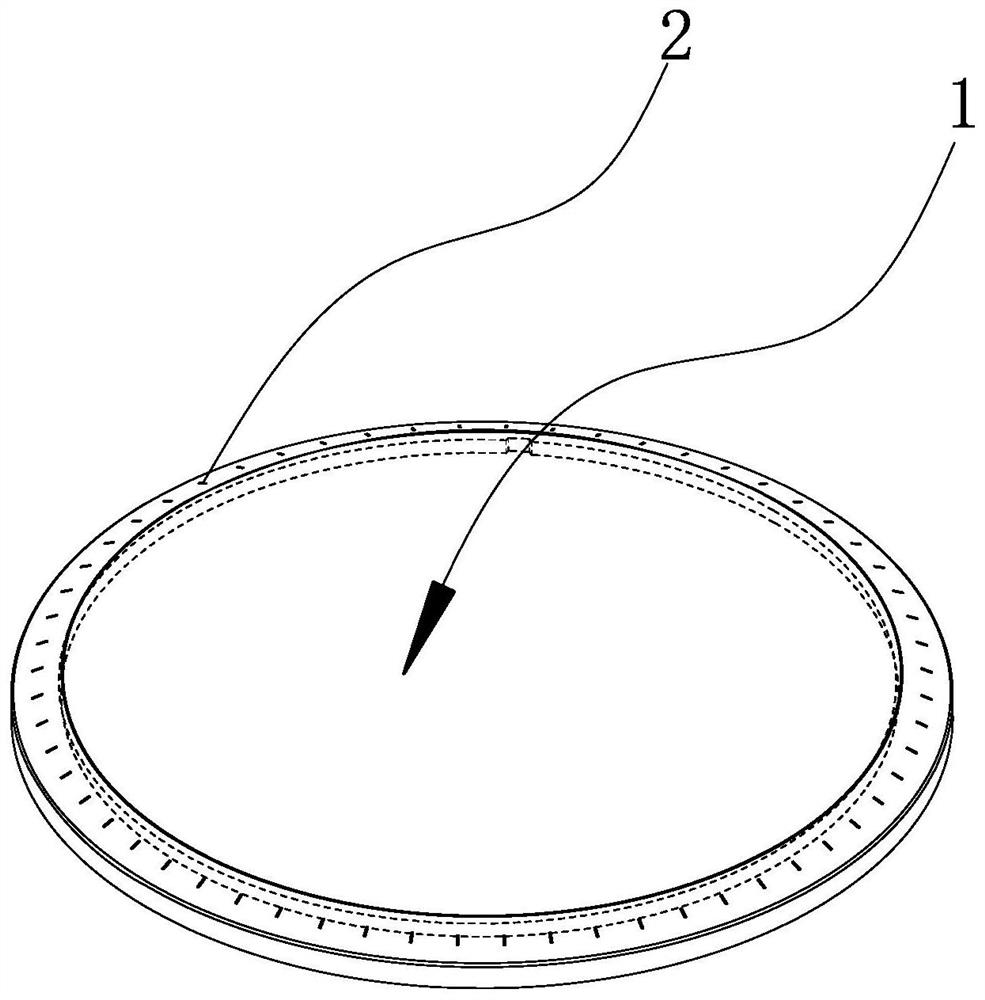

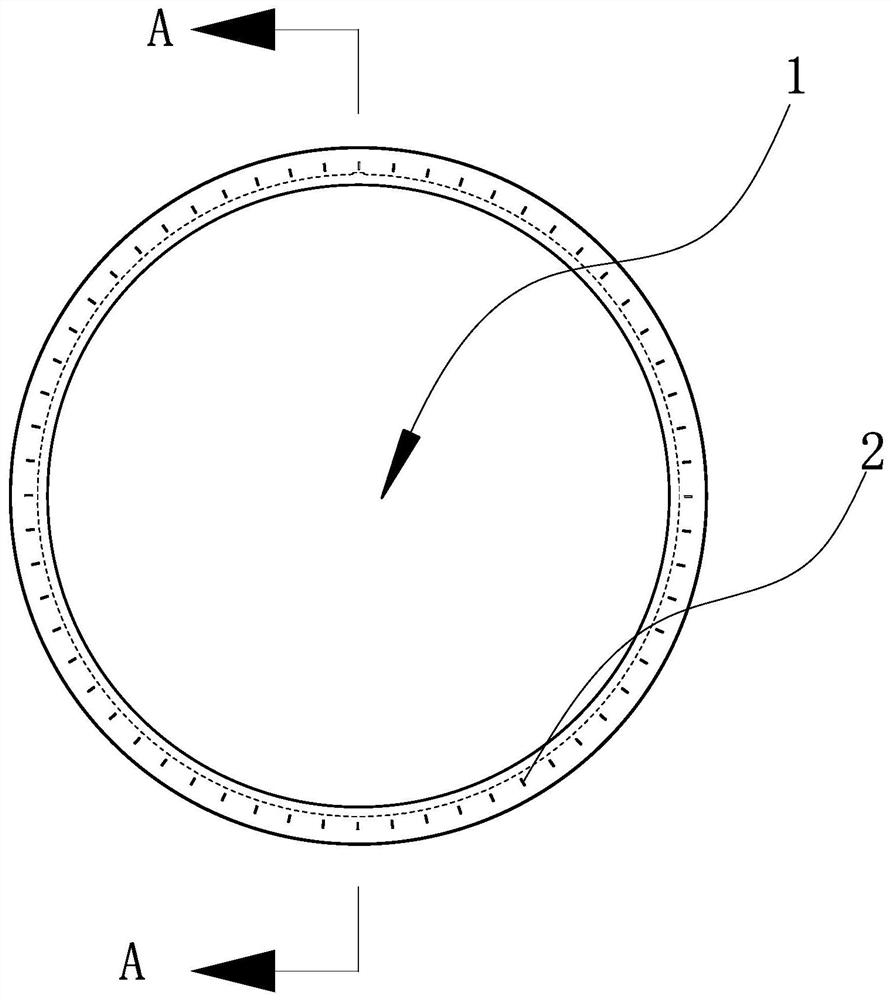

[0034] combine Figure 1-Figure 8 , the laser engraving method of the scale of the 3D glass cover of this watch is applied to the marking of the 3D glass cover 1 by laser marking equipment. The specific operation process is as follows:

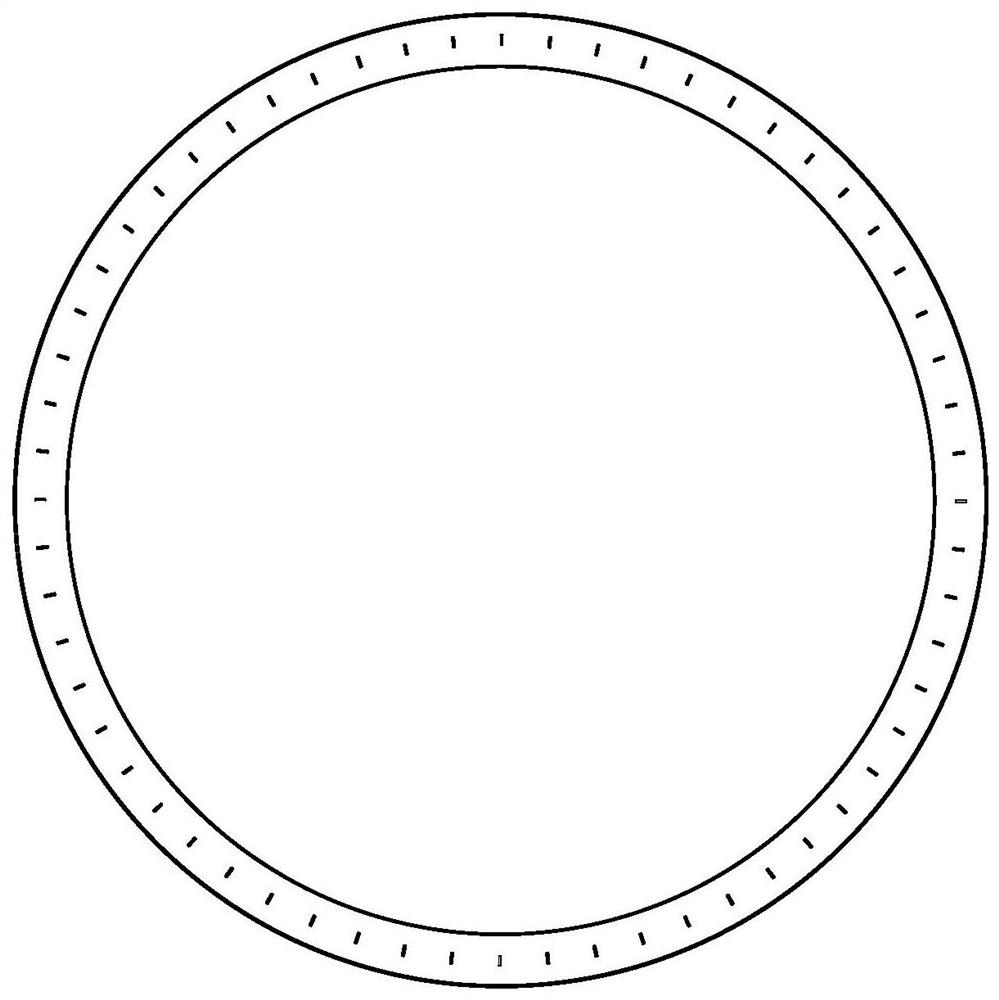

[0035] S1: Put the 3D glass cover 1 to be processed on the fixture of the marking machine and place it on the working platform in the marking area below the marking machine; here, a UV picosecond marking machine is used, and for 3D glass The surface of the watch cover 1 means that the surface of the watch cover is a curved surface or a three-dimensional 3D shape formed such that the circumference of the edge mark scale is inclined. Here, the 3D glass watch cover 1 to be processed adopts the following figure 1 The 3D glass co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com