Preparation method of superconducting D-type coil for magnetic confinement fusion

A magnetic confinement fusion, D-type technology, applied in the direction of superconducting magnet/coil, coil manufacturing, inductor/transformer/magnet manufacturing, etc., can solve the problems of troublesome winding operation, easy to generate stress and strain, and decrease in mechanical strength, and achieve guaranteed Current-carrying performance, avoiding stress and strain, and enhancing the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

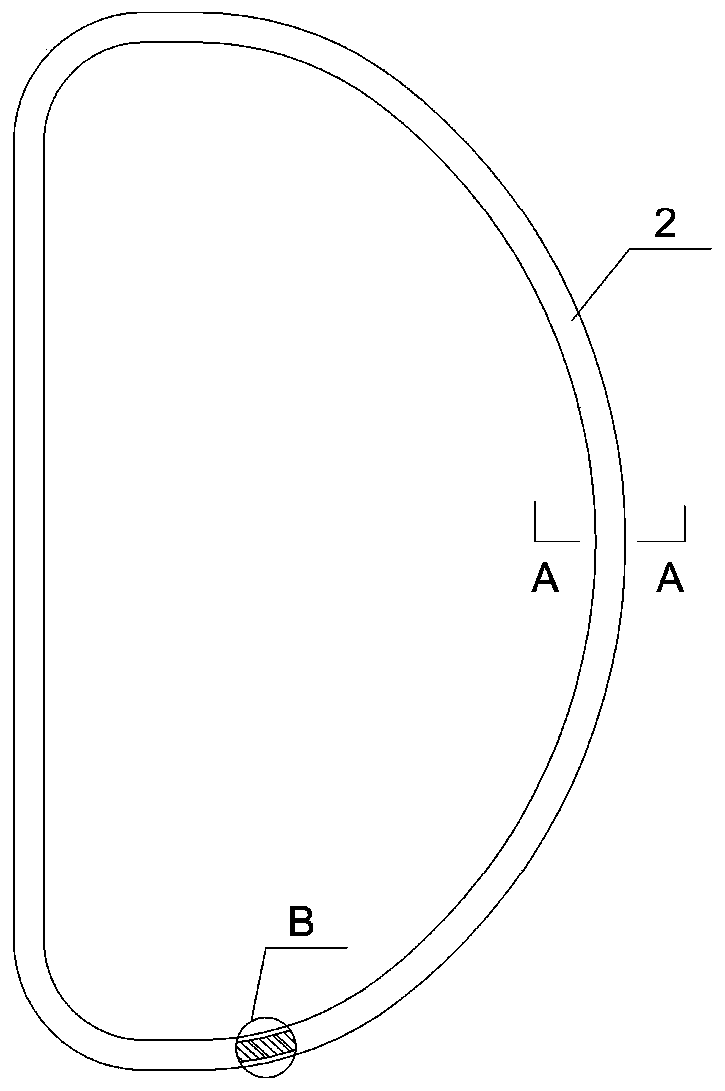

[0028] Figure 1-3 As shown, a specific embodiment of the present invention is a method for preparing a superconducting D-shaped coil for magnetic confinement fusion, comprising the following steps:

[0029] A. Preparation of Coil Skeleton

[0030] Process the high-strength metal round tube into a D-shaped shape to obtain the coil skeleton;

[0031] B. Coil winding

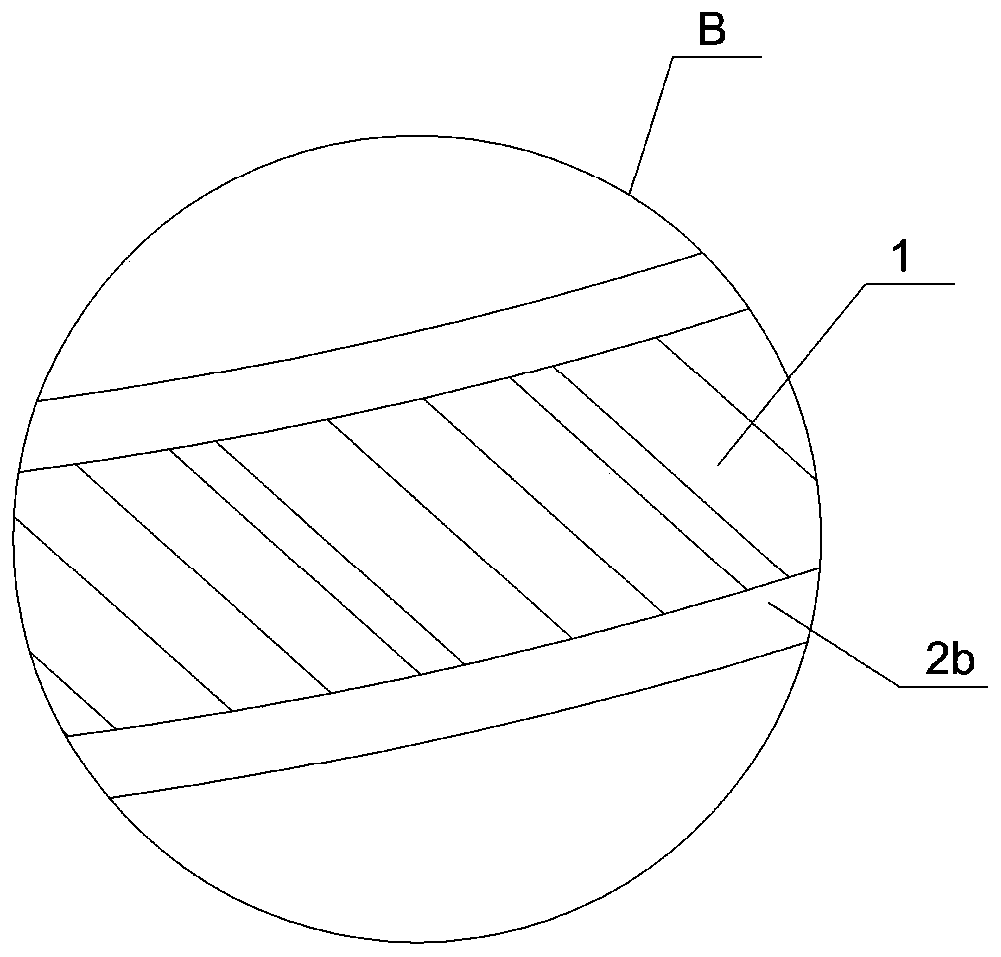

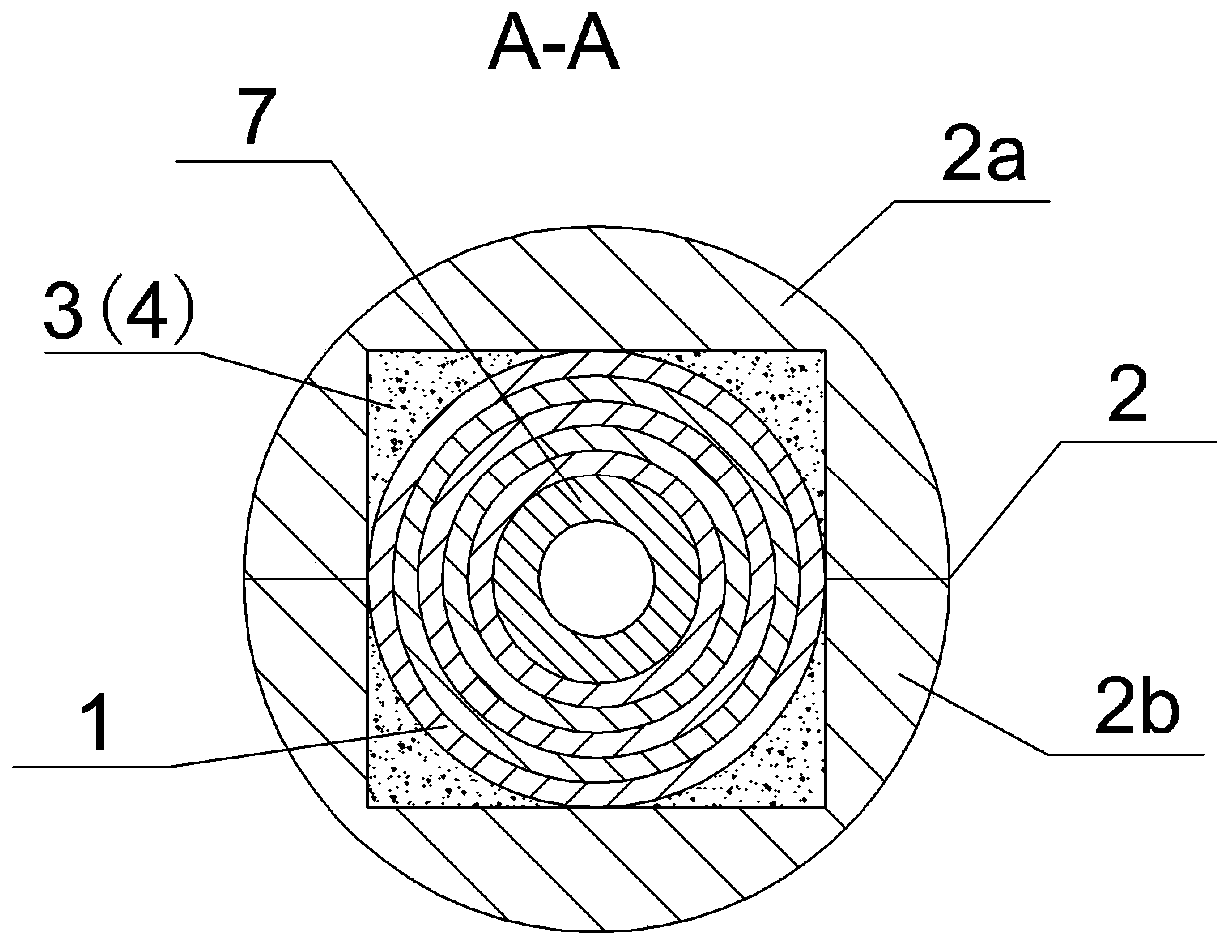

[0032] Several high-temperature superconducting tapes 1 are spirally wound side by side on the coil frame to form a multi-layer coil winding layer, and the high-temperature superconducting tapes 1 of adjacent winding layers are staggered by a distance of 1 / 2-1 / 3 of the strip width; Obtain the superconducting D-type coil embryo body;

[0033] C. Coil curing

[0034] Using vacuum impregnation equipment to impregnate and cure the superconducting D-shaped coil body with epoxy resin 3 or paraffin 4 to obtain a cured superconducting D-shaped coil;

[0035] D. Armor strengthening

[0036] Place the lower half of th...

Embodiment 2

[0038] figure 1 , 2 , 4 show that this example is basically the same as Example 1, the only difference is that a Kapton insulating film 5 is embedded between the layers of the multilayer coil winding layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com