Power mechanism and hand-held tool using power mechanism

A technology for power mechanisms and tools, applied in manufacturing tools, electromechanical devices, structural connections, etc., can solve problems such as low torque, poor power conversion efficiency, and unstable hand-held tool speed control, reducing risks and achieving stable power conversion efficiency. , Improve the effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The implementation of the present invention is described below with specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific embodiments.

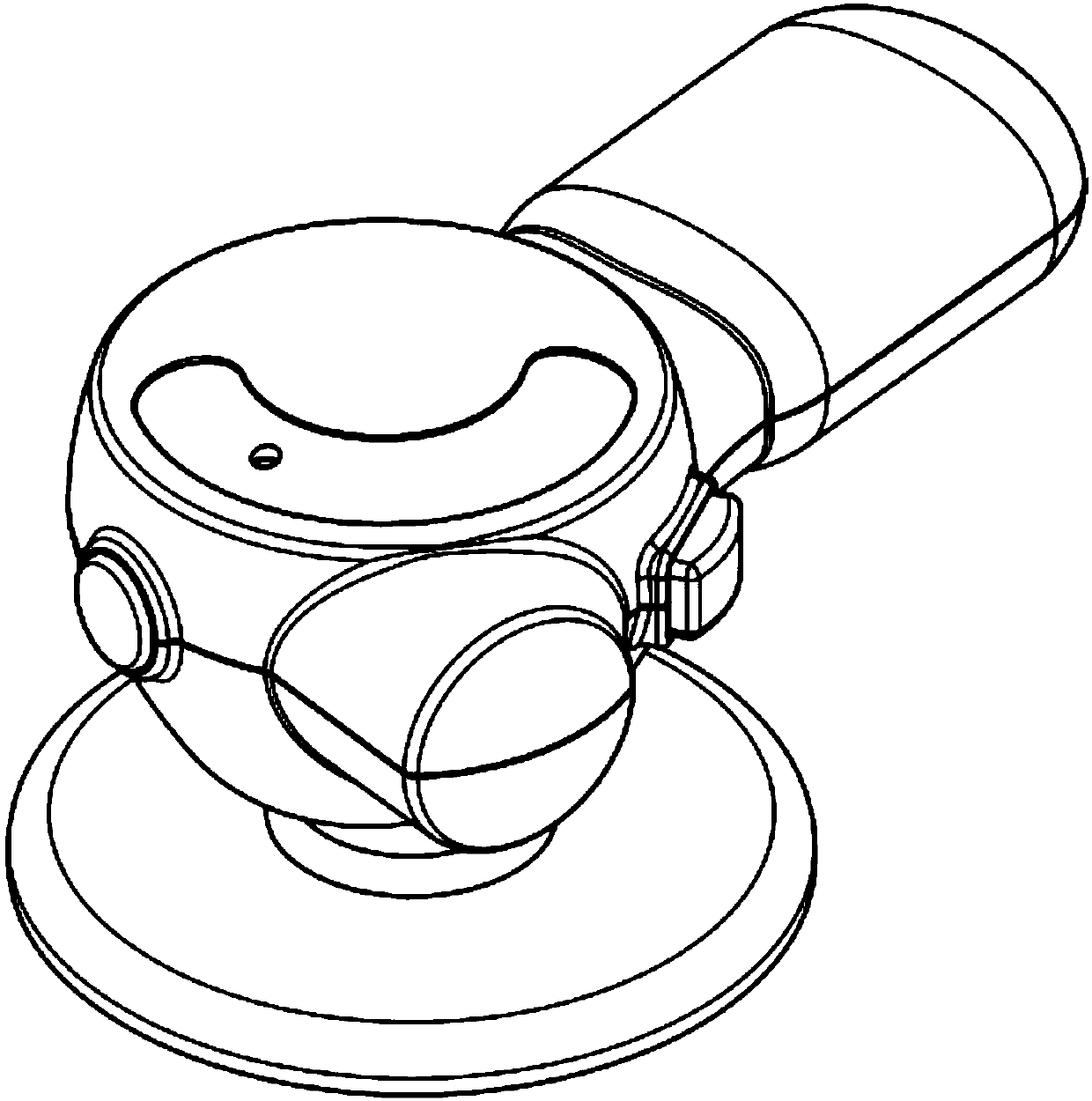

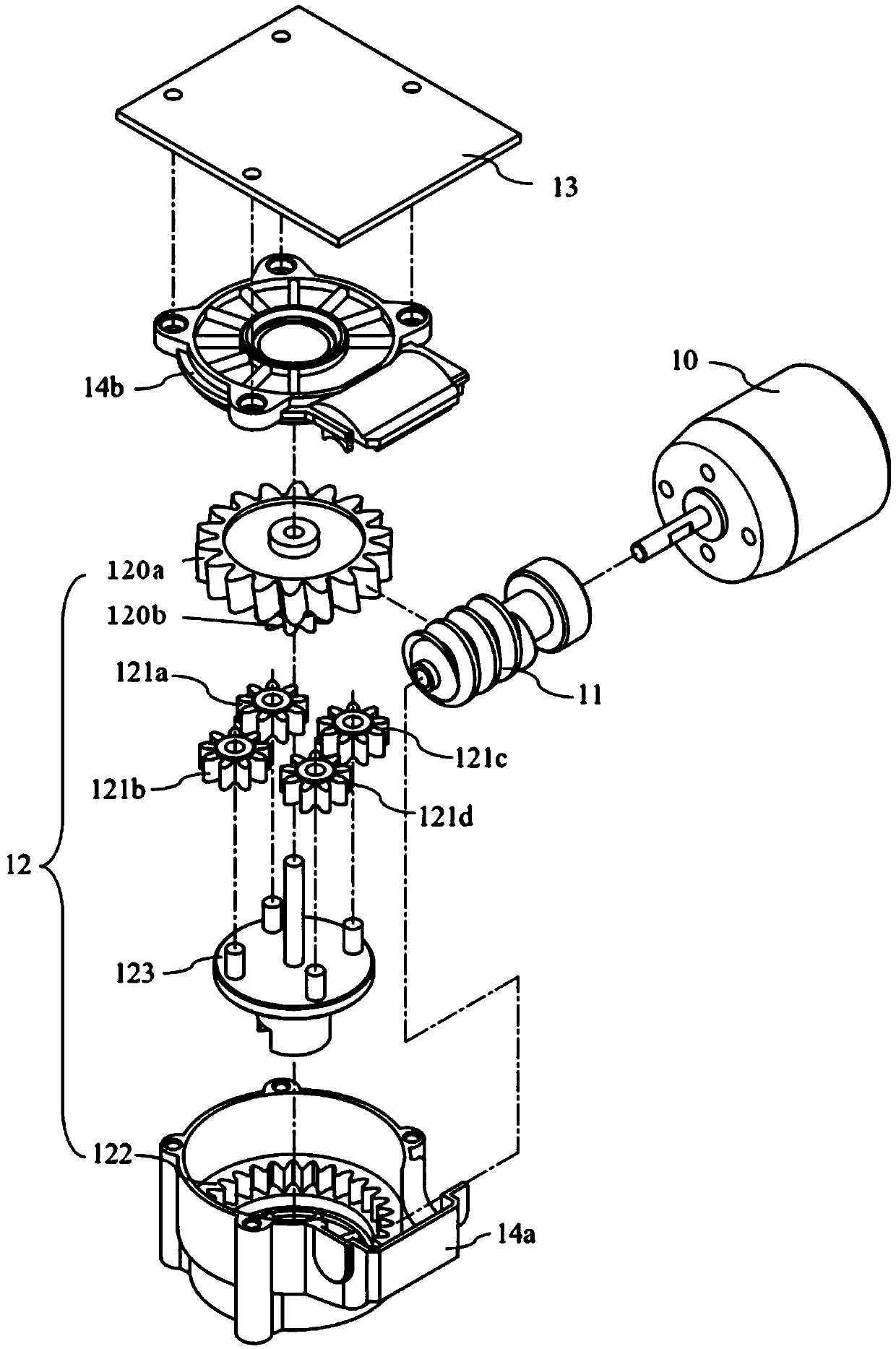

[0043] see figure 1 , figure 1 It is a schematic diagram of the appearance of the hand tool according to the first embodiment of the present invention. The power mechanism of the present invention is applied in such as figure 1 Among the hand tools shown, more specifically, the motor is used as the main power source and the hand tools are convenient to be used by hand.

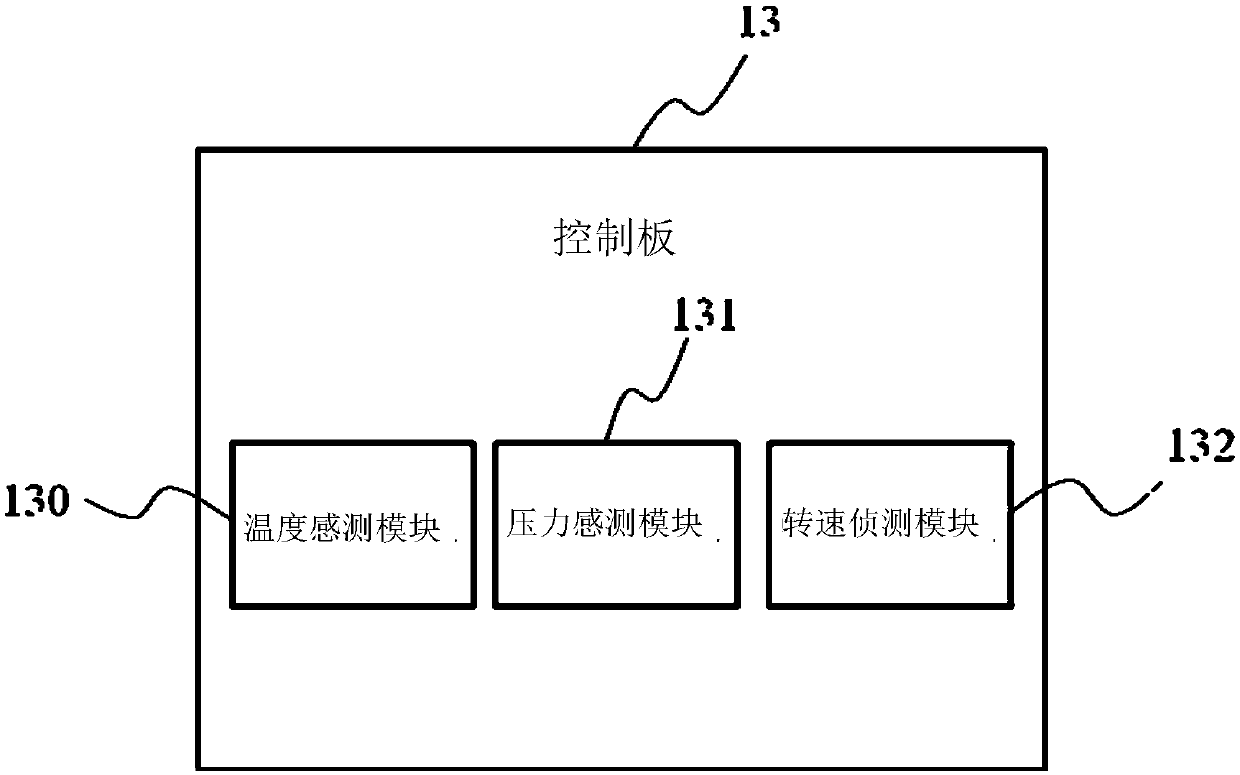

[0044] Generally speaking, hand-held tools are often used for cleaning, grinding, waxing, etc. Taking cleaning as an example, the tool parts (such as brushes) of the hand-held tool will contact objects and cause friction, so the power mechanism of the hand-hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com