Immersive frying, cooking and marinating machine

An immersion and conveyor belt technology, applied in the field of immersion frying and cooking marinade, can solve the problems of limited time for mass production, unsuitable for continuous processing, and inability to cool immediately, and achieve the effect of ingenious structure, reasonable design, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

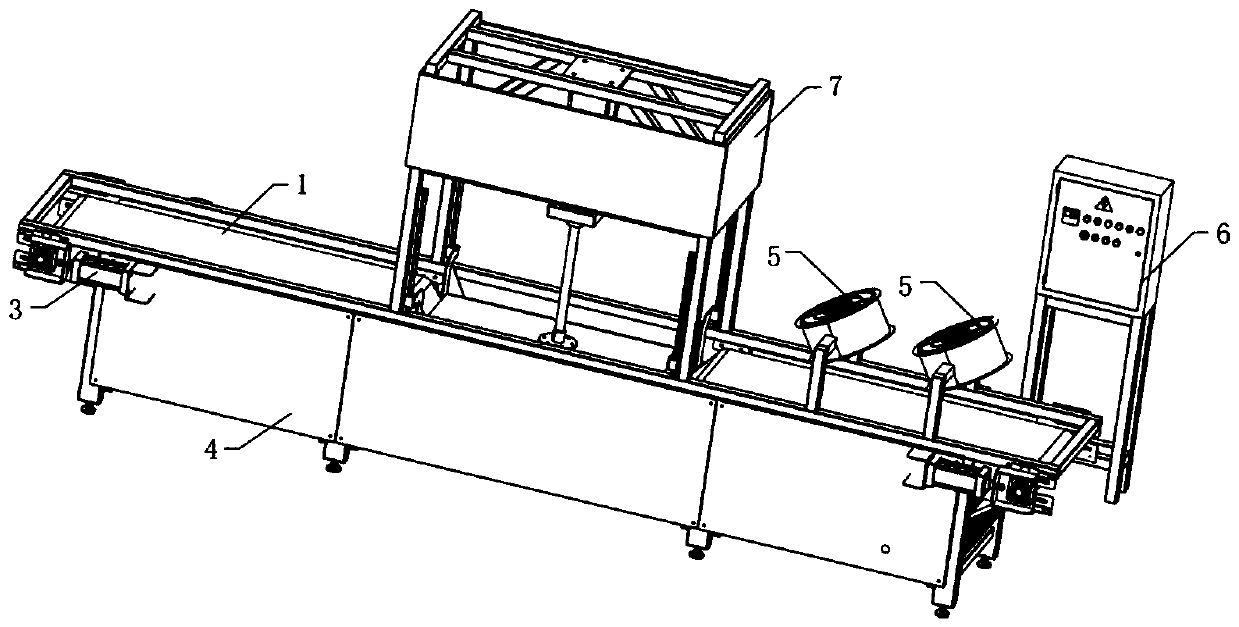

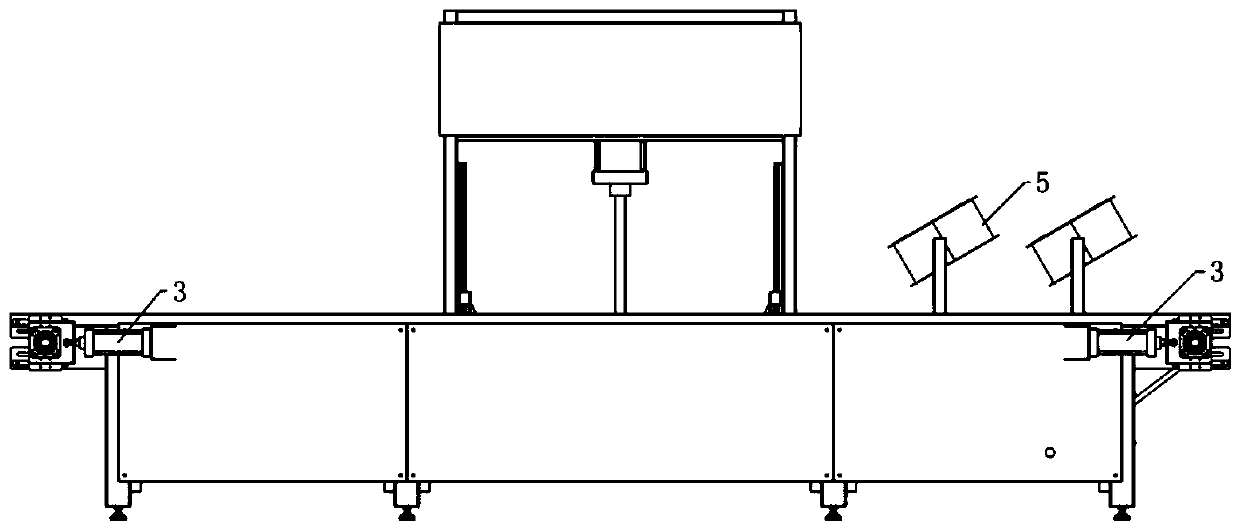

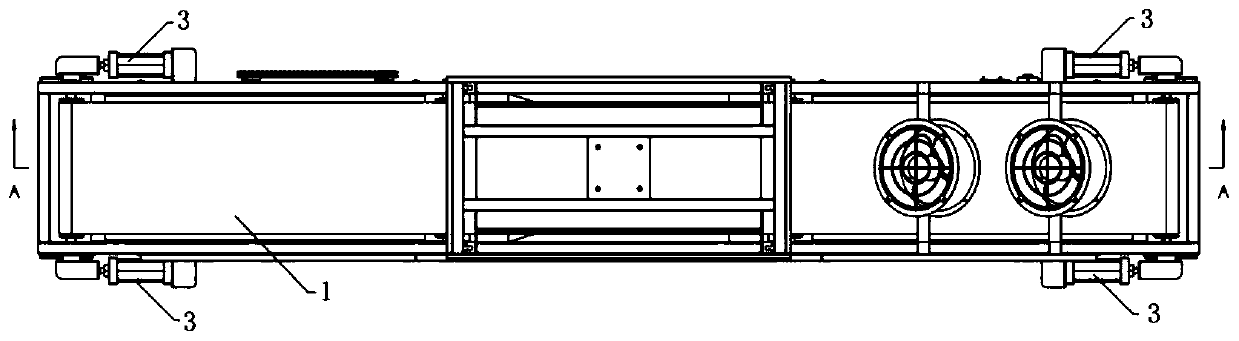

[0046] Embodiment one: if Figure 1-Figure 17 as shown,

[0047] An immersion type frying and cooking stew making machine, comprising a frame body 2 and a processing pot 26 installed under the frame body, a conveyor belt 1 whose middle part can sink to the processing pot is installed on the frame body 2, and at the same time, the conveyor belt A pressing mechanism that drives the middle part of the conveyor belt to sink into the processing pot is installed above.

[0048] In this embodiment, the conveyor belt is a high temperature resistant mesh structure.

[0049] In this embodiment, the conveyor belt 1 is a closed conveyor belt. Adjusting rollers 13 are arranged at both ends of the conveyor belt. retractable mechanism,

[0050] A left support roller 9 and a right support roller 10 are respectively arranged on the left and right sides of the middle part of the conveyor belt, and the left support roller 9 and the right support roller 10 are installed on the frame body 2 throu...

Embodiment 2

[0068] Embodiment two: if Figure 18-Figure 24 as shown,

[0069] An immersion type frying and cooking stew making machine, comprising a frame body 2 and a processing pot 26 installed under the frame body, a conveyor belt 1 whose middle part can sink to the processing pot is installed on the frame body 2, and at the same time, the conveyor belt A pressing mechanism that drives the middle part of the conveyor belt to sink into the processing pot is installed above.

[0070] In this embodiment, the conveyor belt 1 is a closed conveyor belt. Adjusting rollers 13 are arranged at both ends of the conveyor belt. retractable mechanism,

[0071] A left support roller 9 and a right support roller 10 are respectively arranged on the left and right sides of the middle part of the conveyor belt, and the left support roller 9 and the right support roller 10 are installed on the frame body 2 through bearings and bearing seats respectively,

[0072] The left tension roller 8 and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com