Automatic tracing and positioning system for falling-behind spindles corresponding to spun yarn and bobbin linkage defected yarn tubes

A positioning system and fine-link technology, applied in the field of spinning, can solve the problems of time-consuming, labor-intensive efficiency, difficulty, and low efficiency, and achieve the effects of high tracking reliability, reducing production costs, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

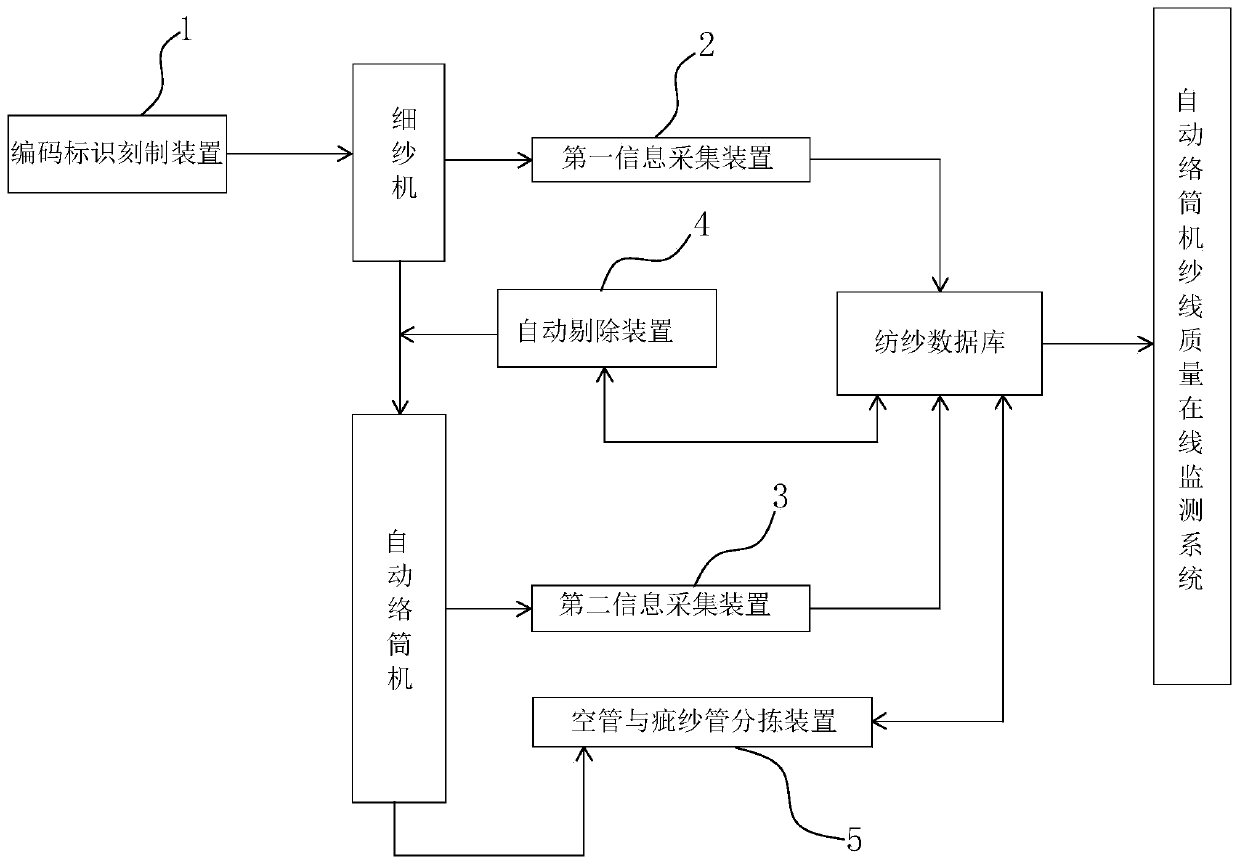

[0055] Such as figure 1 As shown in the figure, an automatic traceability and positioning system corresponding to the backward spindle of the spun yarn linkage defective bobbin includes an engraving device 1 for encoding and marking the spun bobbin, and is used to simultaneously collect the coding information on the spun bobbin and the spun bobbin The first information collection device 2 corresponding to the position information of the spindle, and the second information collection device 3 for collecting the coded information on the bobbin in the automatic winder yarn storehouse.

[0056] The engraving device 1 engraves several codes at intervals on the top circumference of the spun bobbin.

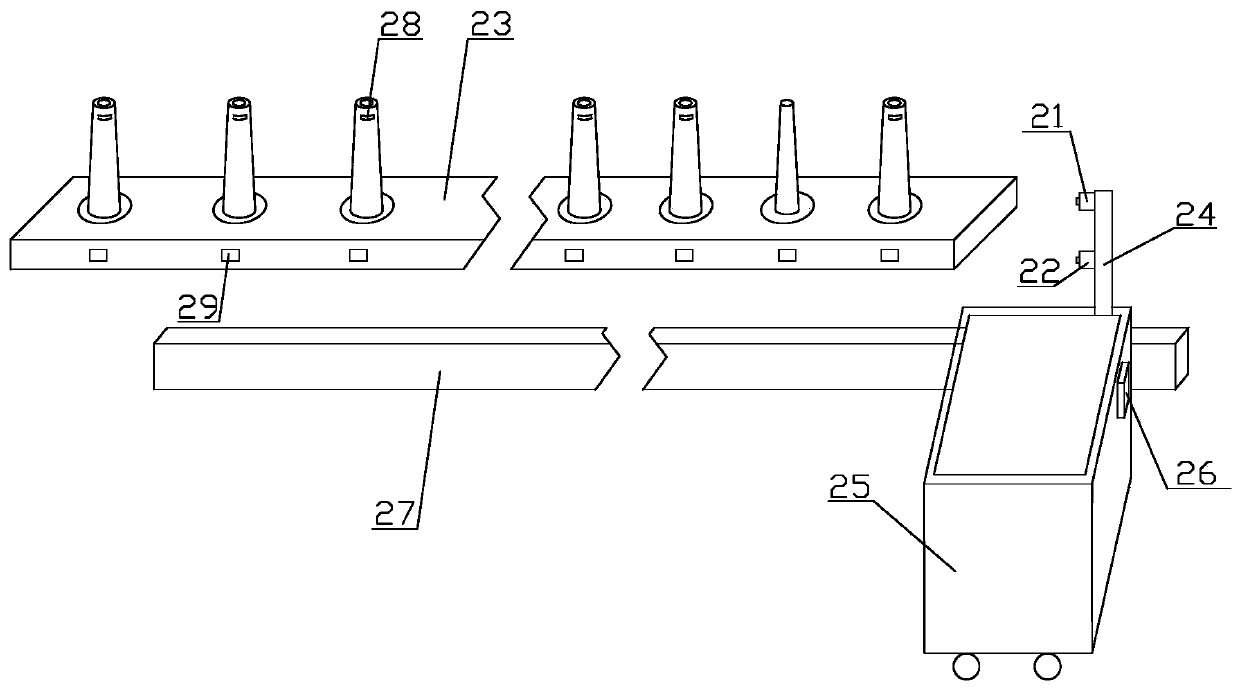

[0057] Such as figure 2 As shown, the first information collection device 2 includes a No. 1 code scanner 21 and a position verification scanner 22. The No. 1 code scanner 21 corresponds to the code setting on the bobbin, and corresponds to each spindle position on the spinning frame....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com