Braking and driving linkage clamping rod hammer

A clamping rod and linkage technology, applied in the driving device of hammer, forging/pressing/hammering machinery, drop hammer, etc., can solve the damage of driving device and braking device, the damage of brake ring and roller, and the inability to rotate downward. lever, etc., to reduce the operating intensity and stabilize the braking force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

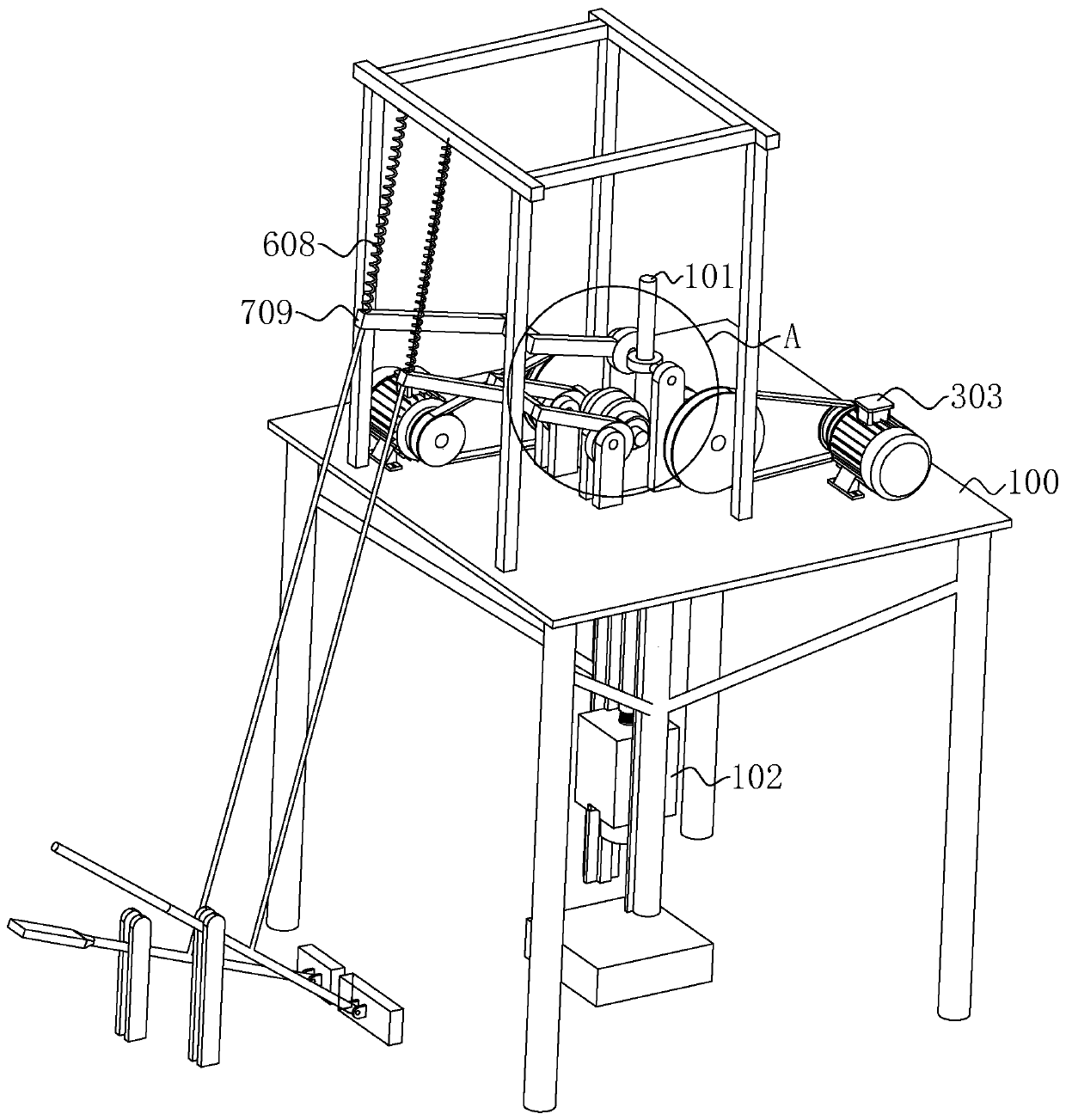

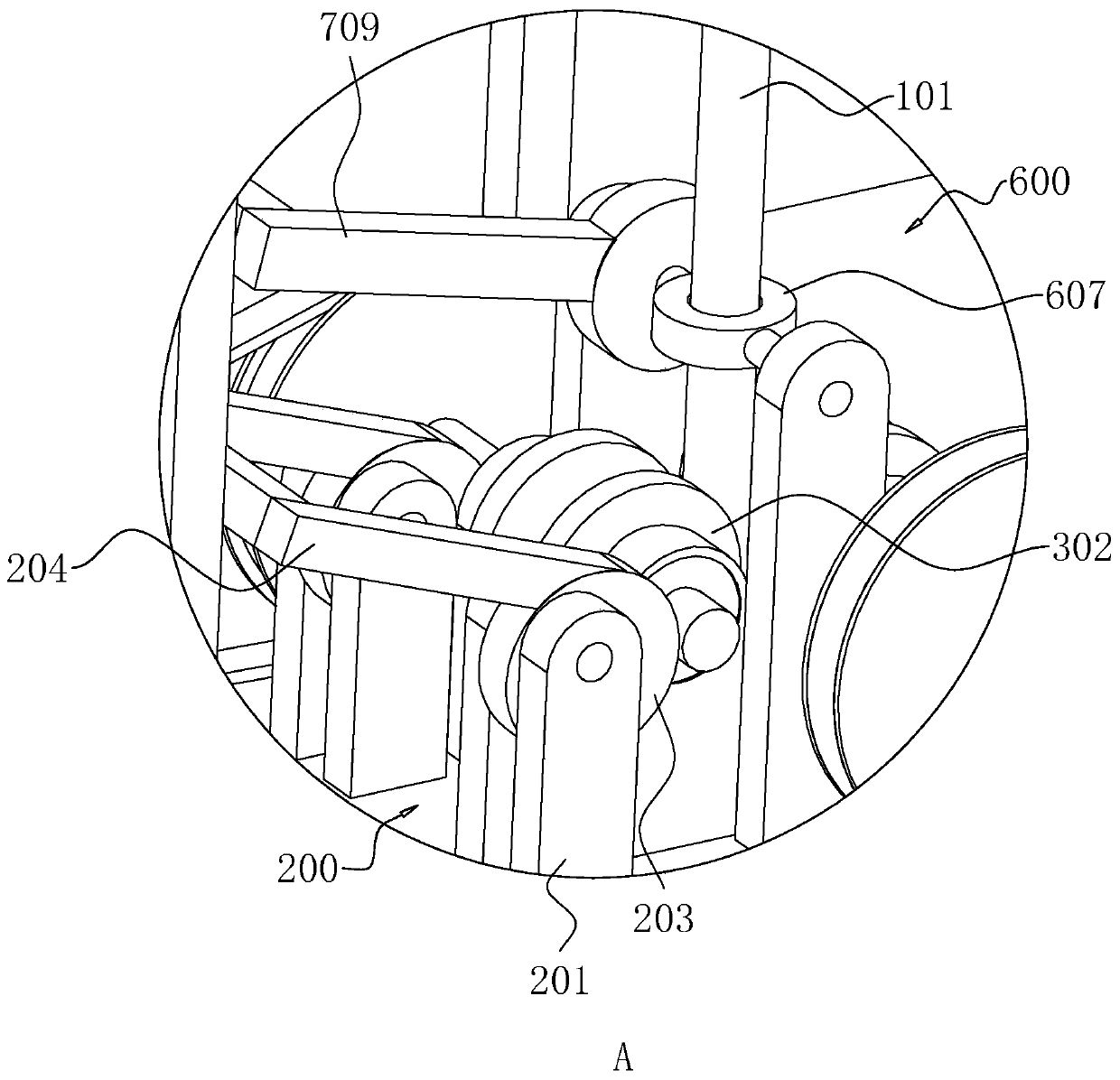

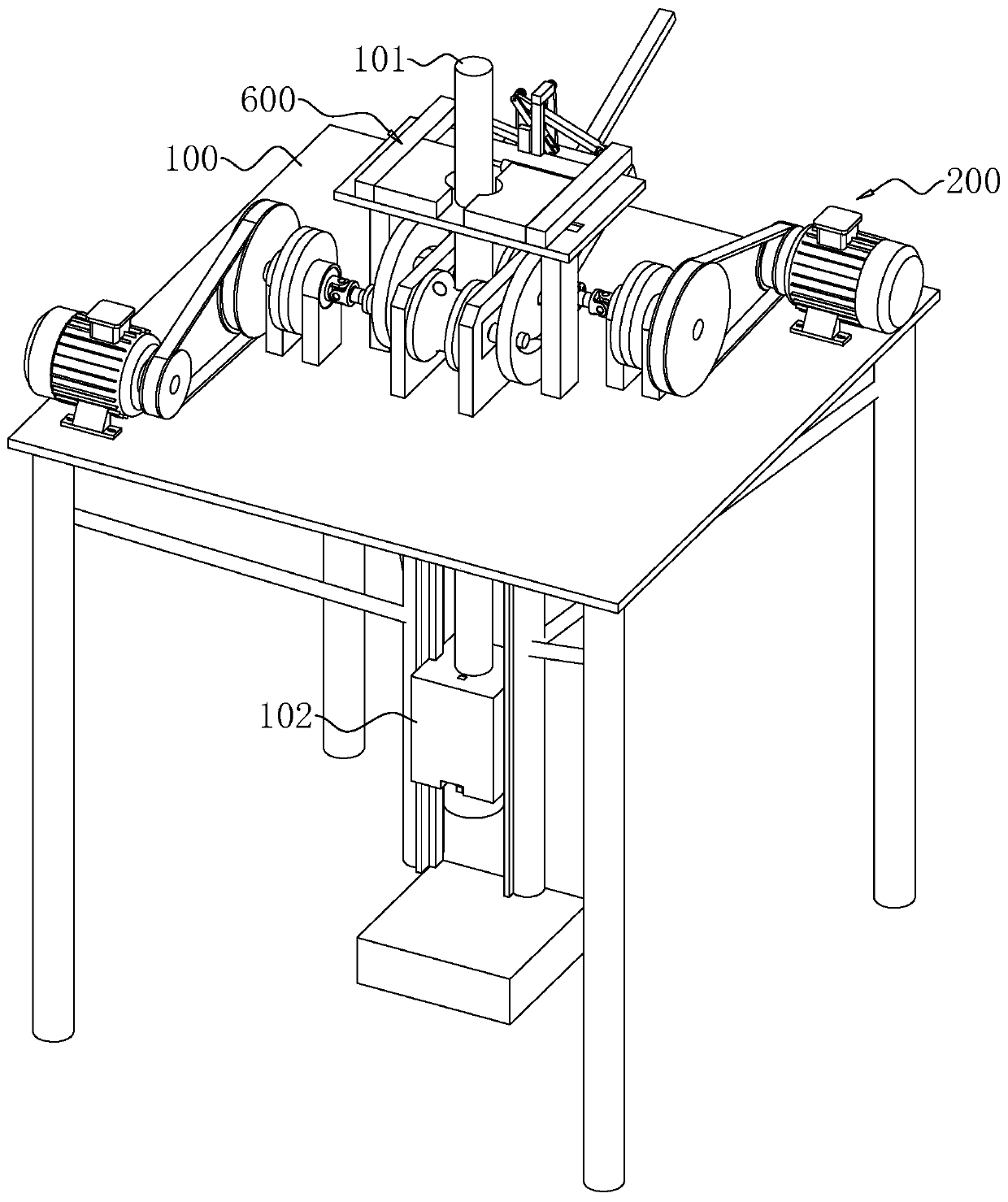

[0045] Example: such as image 3 Shown is a brake and drive linkage clamp rod hammer disclosed in the present invention. It includes a frame 100. A hammer rod 101 is vertically slidably connected to the frame 100. A hammer head 102 is fixedly connected to the lower end of the hammer rod 101. The frame 100 is connected with a buffer drive device 200 that drives the hammer rod 101 to slide vertically, and the frame 100 is connected with a brake device 600 that locks the hammer rod 101.

[0046] Such as Figure 4 As shown, the buffer drive device 200 includes a mounting seat 201, which is fixedly connected to the frame 100 of the clamp rod hammer. The mounting seat 201 is provided with a power structure 300 for applying an upward force to the hammer rod 101 to lift the hammer head 102. The mounting seat 201 is also provided with an operating structure 400, which can control whether the force of the power structure 300 is transmitted to the clamp rod hammer rod 101.

[0047] Such as ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap