Novel laser marking machine with automatic detection function

A laser marking machine and automatic detection technology, applied in the field of laser marking, can solve the problems of low efficiency, waste of manpower and material resources, high defect rate, etc., and achieve the effect of improving efficiency, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

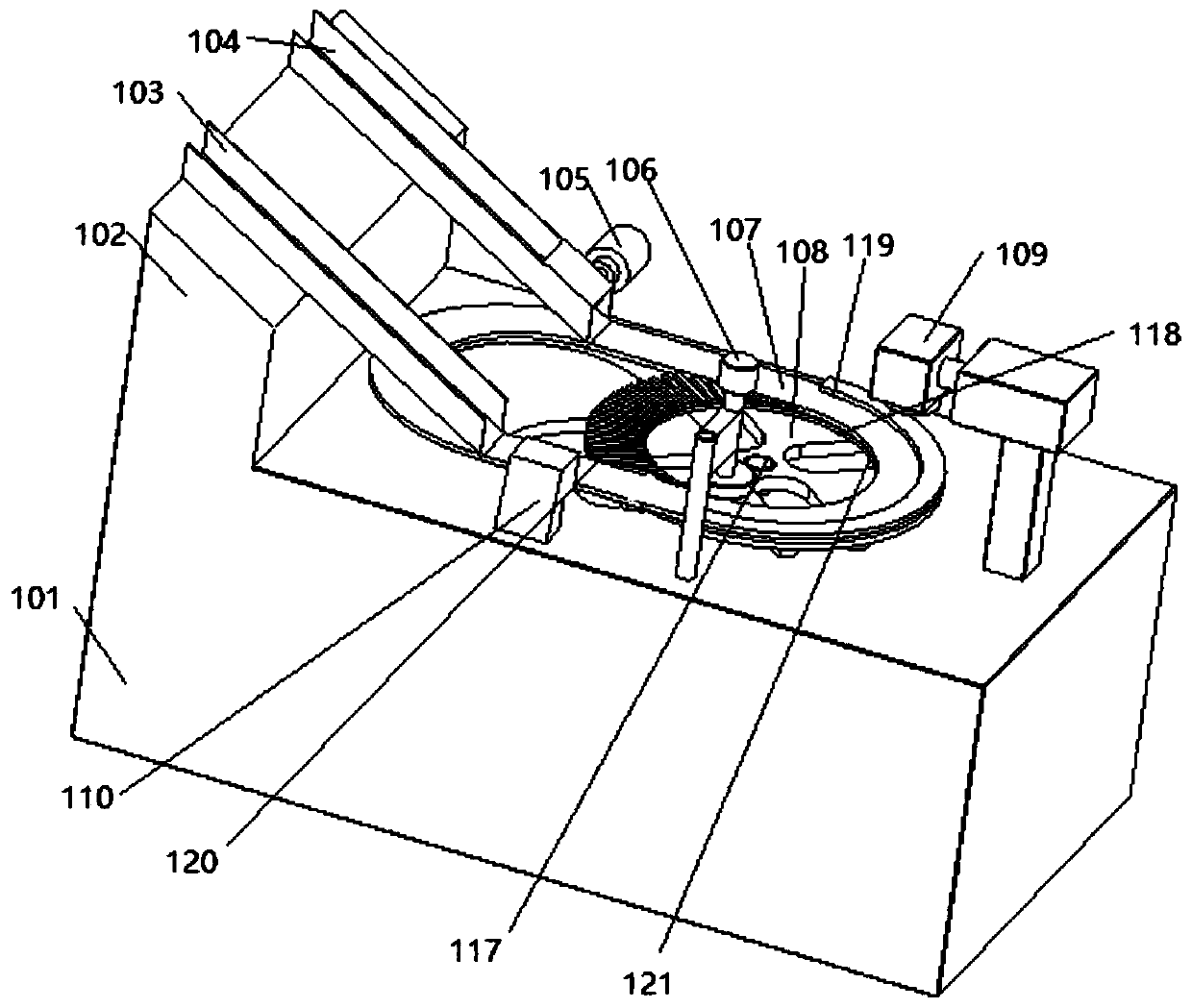

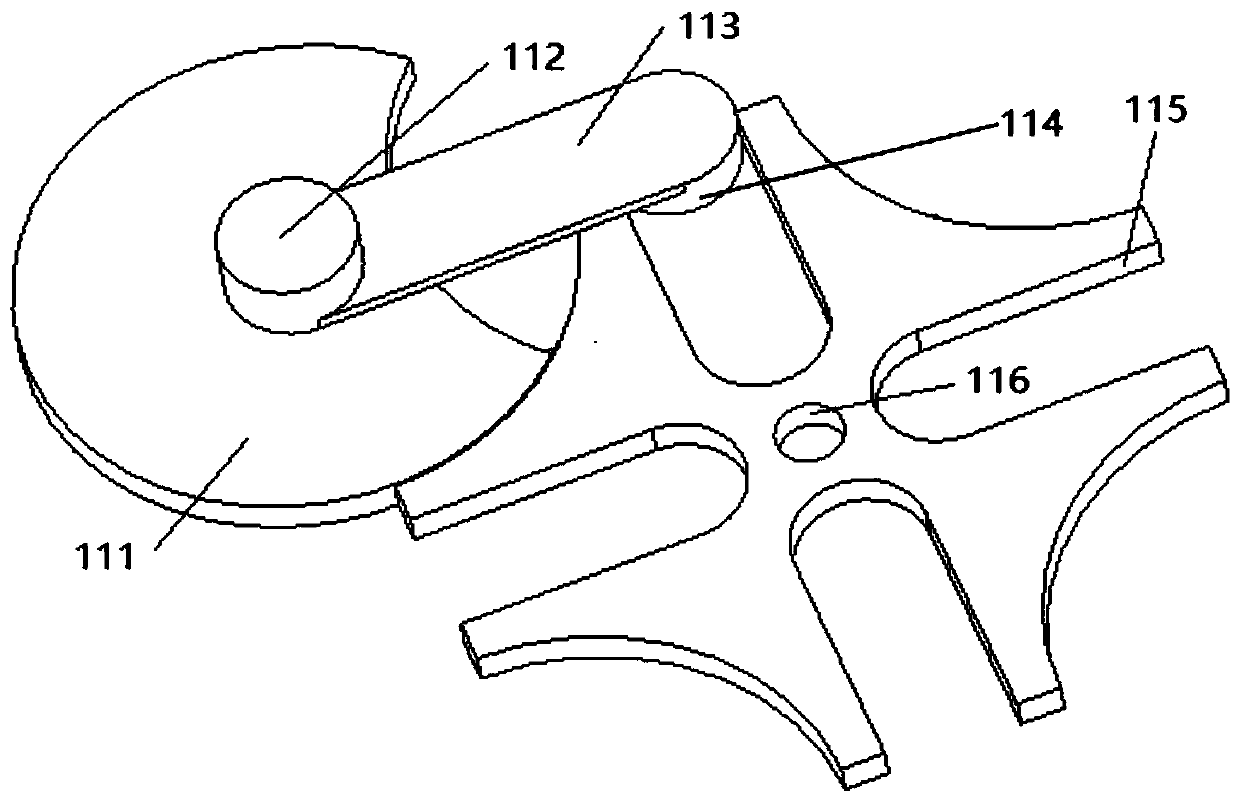

[0014] refer to Figure 1 to Figure 2 , the laser marking machine includes a bearing platform 101, an inclined platform 102, a discharge device 103, a feeding device 104, a blocking cylinder 105, a detection device 106, a conveyor belt 107, a sheave 108, a laser marking machine 109, no Good product screening device 110, cylindrical convex rod 117, servo motor 112, rocker 113, circular ring 118, annular groove 119, driving dial 111, cylindrical pin 114, radial groove 115, cylindrical through hole 116, ring gear 120, Segment gear 121; a cylindrical protruding rod 117 and an inclined platform 102 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com