Paint color mixing box for outdoor huge paintings

A color box and huge technology, applied in painting tools, decorative arts and other directions, can solve the problems of insufficient stirring, inconvenience, insufficient color palette capacity, etc., and achieve convenient portability, convenient use and good color matching effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

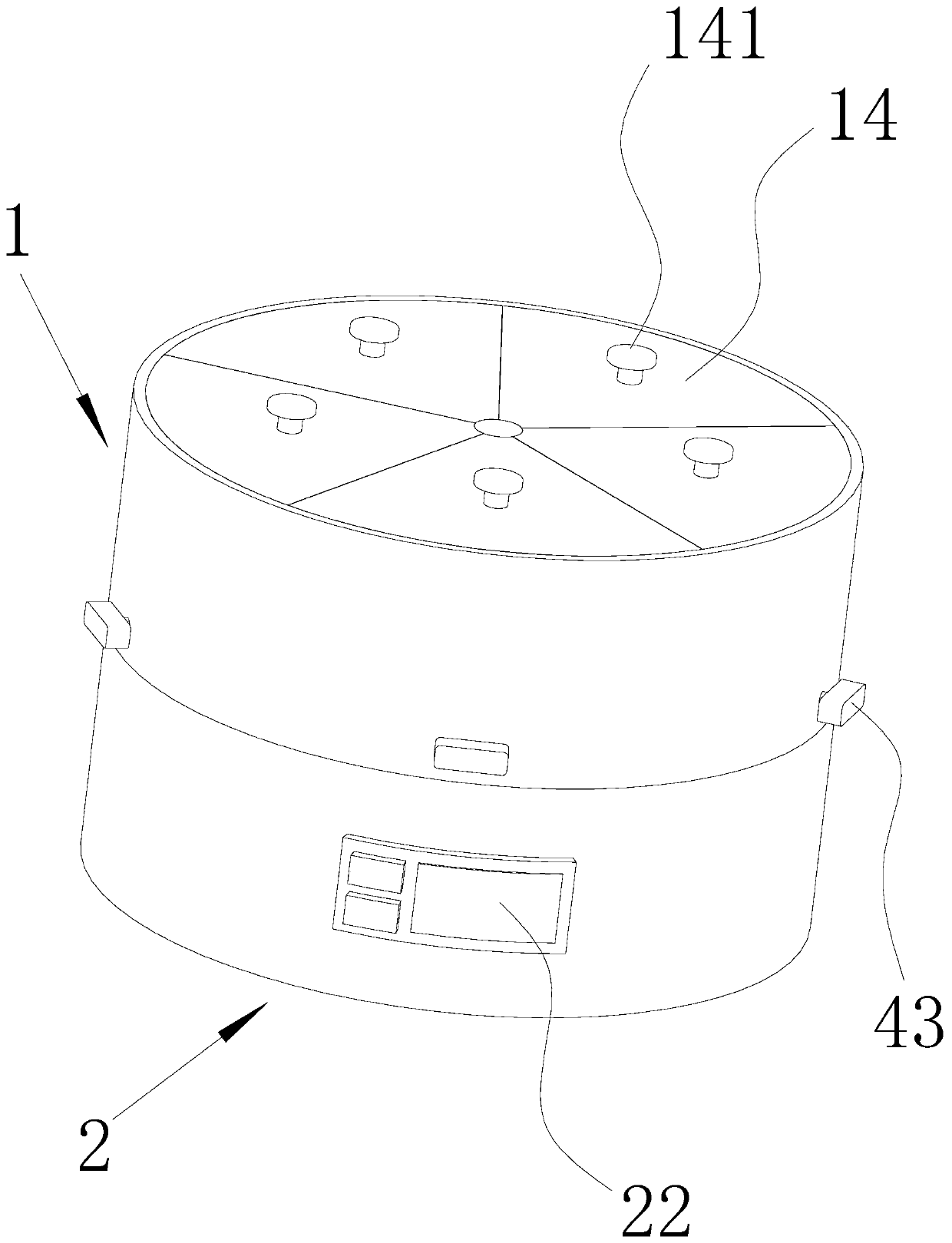

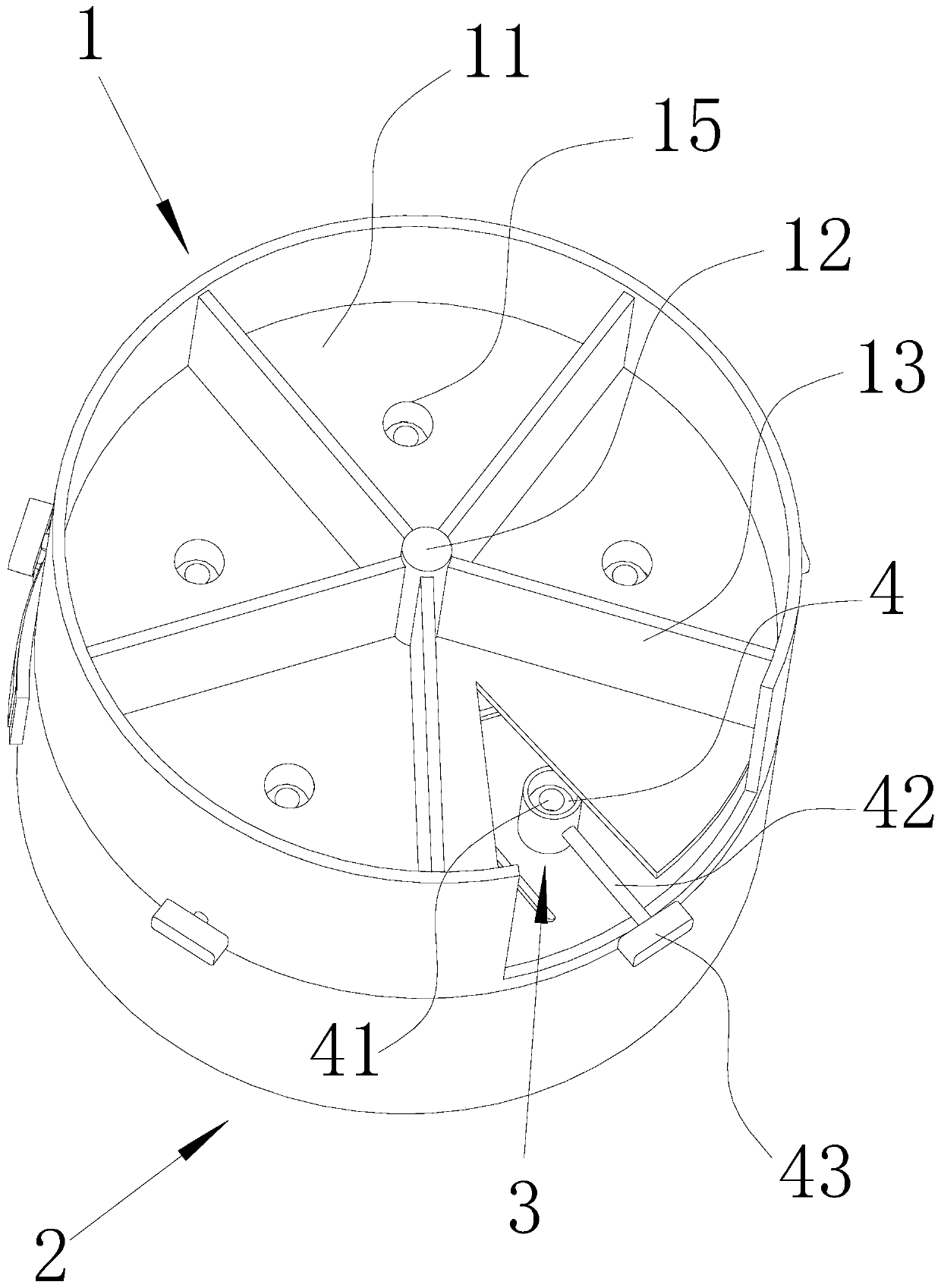

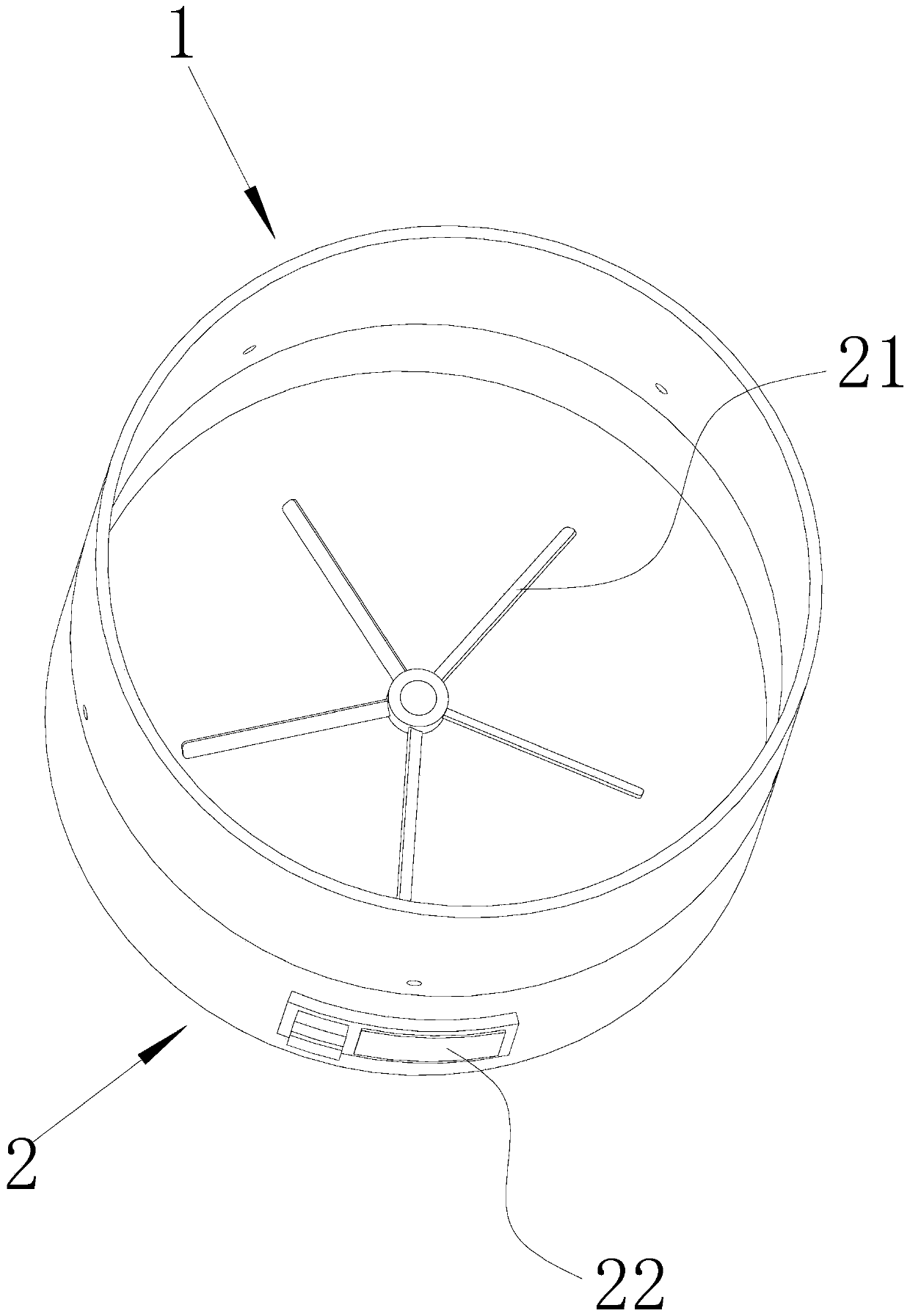

[0020] see Figure 1-Figure 4 , a kind of pigment toning box used for outdoor huge paintings, comprising an upper box body 1, a lower box body 2, the lower side of the upper box body 1 is flexibly connected with the upper side of the lower box body 2;

[0021] The upper box body 1 is a vertically arranged cylindrical body with upper and lower openings. The lower part of the upper box body 1 is provided with a liner plate 11 arranged horizontally and matched with the upper box body 1. The upper center of the liner plate 11 is provided with a There are vertically arranged positioning columns 12, and the positioning columns 12 are provided with five vertically arranged partitions 13 whose length direction extends radially along the liner 11, and the lower side of each partition 13 abuts against the liner 11, Five partitions 13 and lining boards 11 divide the upper box body 1 into five fan-shaped chambers with open upper sides, and each fan-shaped chamber is provided with an upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com