An indirect tire pressure monitoring system and method

A tire pressure monitoring system, an indirect technology, applied in tire measurement, tire parts, transportation and packaging, etc., can solve the impact of tire pressure sensor power, wear and tear on functional stability, delay and electromagnetic interference, and increase user costs and other issues, to achieve the effect of reducing maintenance costs, reducing hardware usage costs, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

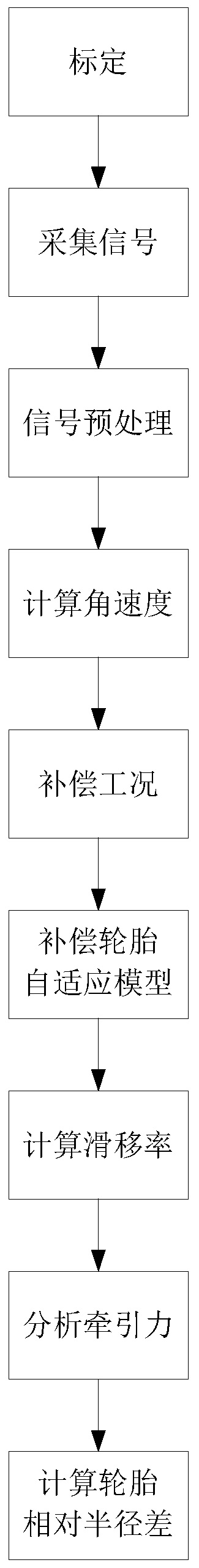

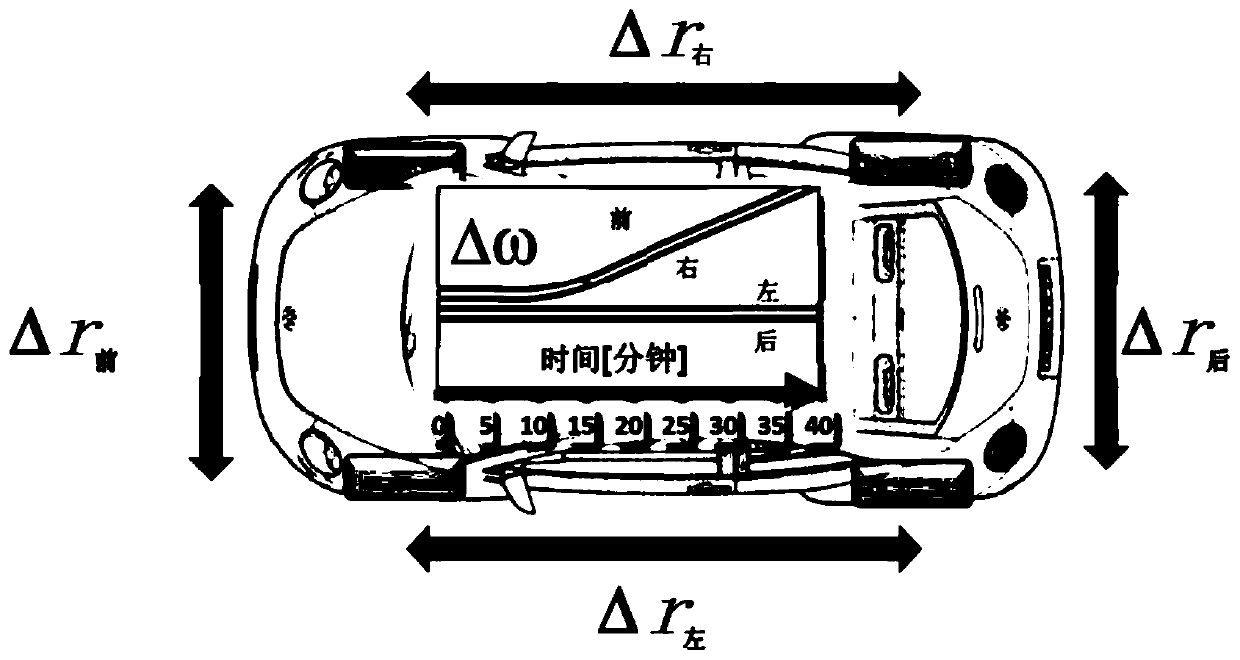

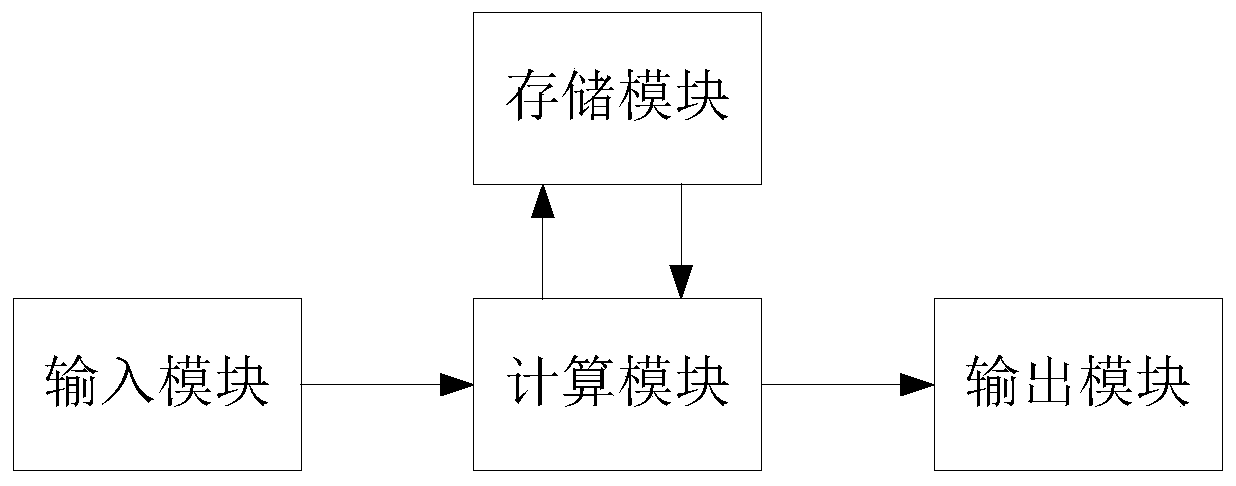

[0040]An indirect tire pressure monitoring system of the present invention comprises a signal preprocessing module, an angular velocity calculation module, a working condition compensation module, a tire self-adaptive model compensation module, a slip ratio calculation module, a traction force analysis module and a sequentially connected signal flow direction. Tire relative radius difference calculation module. The signal input port of the signal preprocessing module is connected with the sensor for receiving the sensor signal and filtering the received signal to eliminate noise; the signal preprocessing module includes a Butterworth type FIR low-pass filter for filtering the received signal Event-based interpolation and band-pass filtering are performed on the original wheel speed data to filter out noise spikes and prevent false ala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com