Buffer device for airship

A buffer device and airship technology, which is applied to lighter-than-air aircraft, aircraft, aircraft parts, etc., can solve the problems of affecting product usability, slow inflation molding time, troublesome air source storage, etc., to reduce molding time and avoid wind resistance and unexpected winding interference, the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

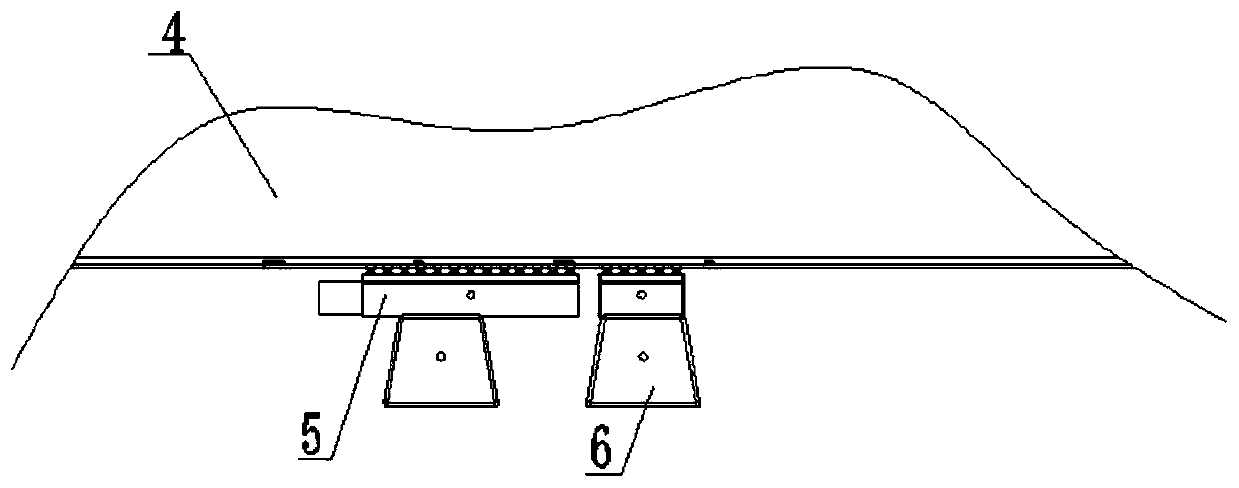

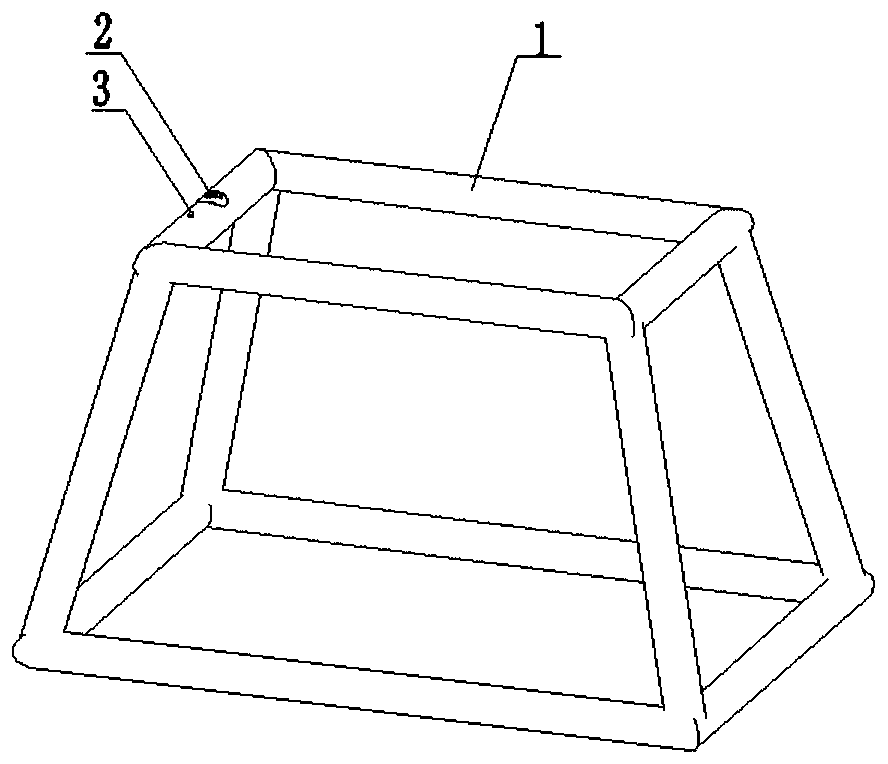

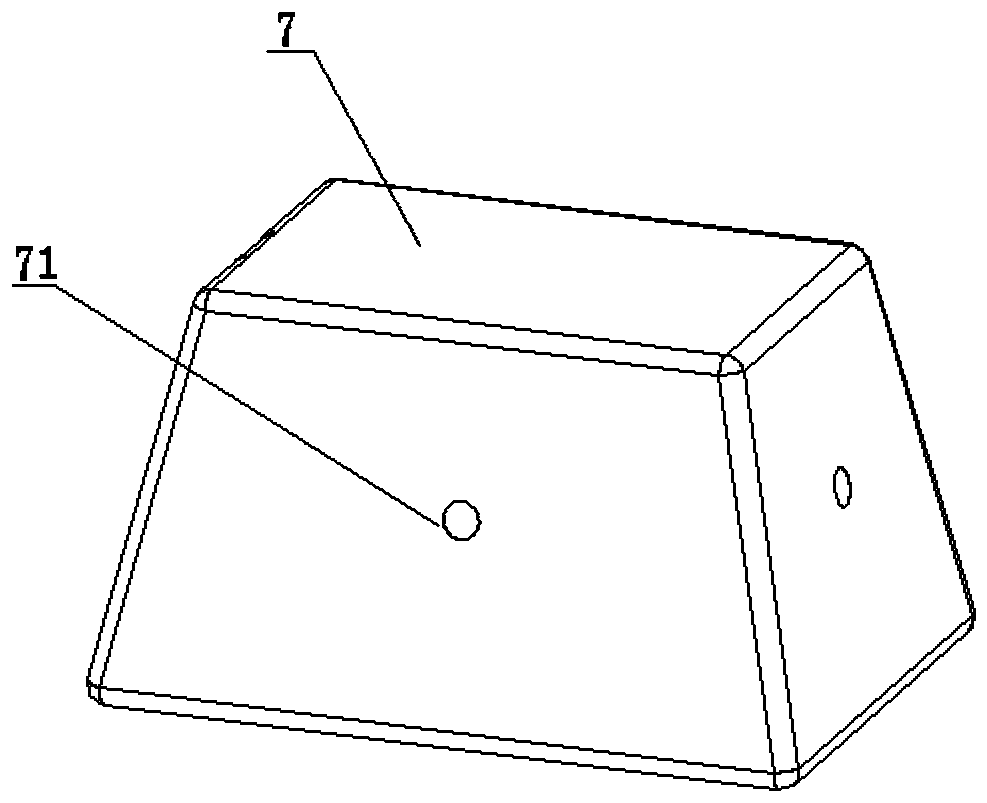

[0030] Such as Figure 1-7 Shown, a kind of cushioning device that is used for airship is made up of cushioning air cushion 6, inflation device, monitoring system. The buffer air cushion 6 includes an inflatable skeleton structure 1 and an outer bag 7, the skeleton structure 1 and the outer bag 7 are made of flexible materials, the skeleton structure 1 is installed in the outer bag 7, and the upper surface of the outer bag 7 is sewn with a rope buckle 12, for connecting with pod 5.

[0031] Skeleton structure 1 is used to inflate cushion air cushion 6 into shape. It is sealed and airtight. After inflated, it is in the shape of a square platform. The edge of the upper surface of skeleton structure 1 is provided with inflation port 2 and air pressure sensor 3 .

[0032] The outer bag 7 is the main body that cushions and protects the pod 5 when the cushioning air cushion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com