Electric lifting device for telegraph pole hoop

A technology of electric lifting devices and utility poles, which is applied in transportation and packaging, cranes, etc., can solve problems such as insufficient efficiency, waste of manpower, and unsafety, and achieve the effects of saving time, improving work efficiency, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

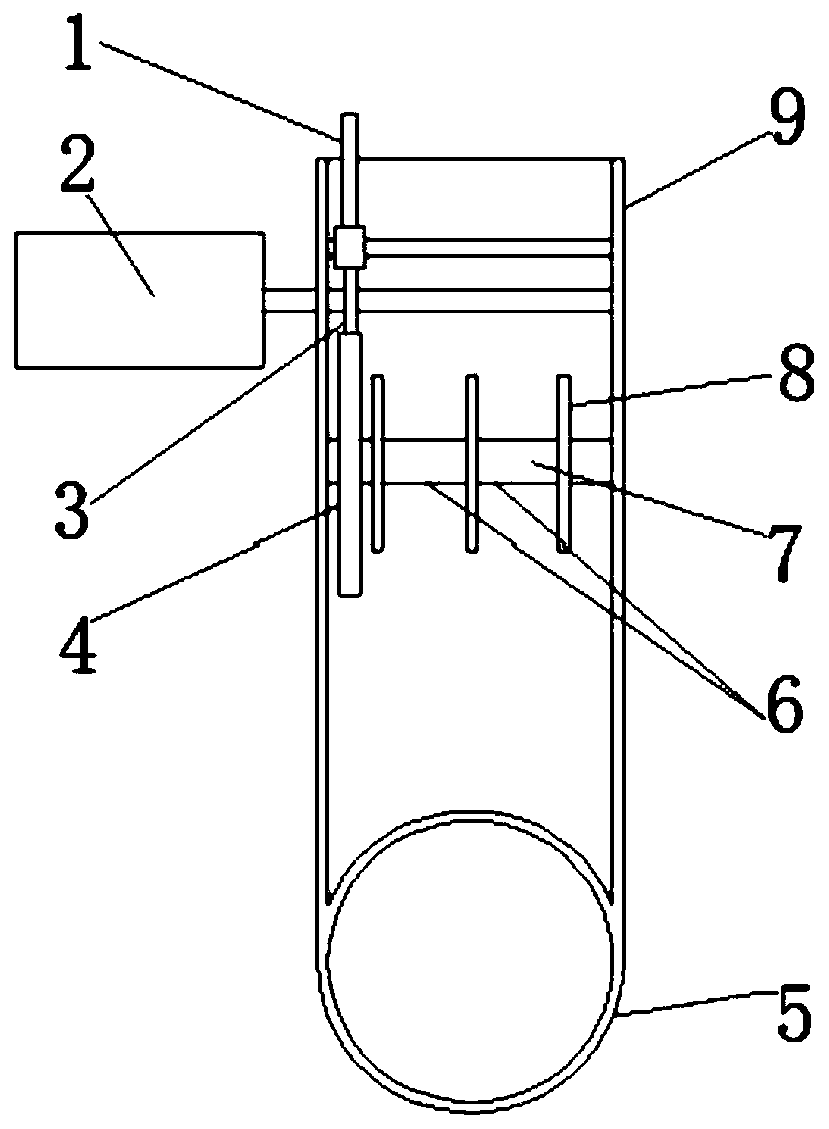

[0022] This embodiment provides an electric hoisting device for utility pole hoops, including a support frame 9, the end of the support frame 9 is fixedly connected with a fixing ring 5, and a motor 2 is installed on the side wall of the support frame 9, and the motor 2 The end of the output shaft of 2 extends into the support frame 9, the outer wall of the output shaft of the motor 2 is fixedly connected with the pinion 3, the inner wall of the support frame 9 is connected with the winding shaft 6, and the outer wall of the winding shaft 6 is fixed A large gear 4 is connected, and the pinion 3 and the large gear 4 mesh with each other. The diameter of the small gear 3 is much smaller than the diameter of the large gear 4. The outer wall of the winding shaft 6 is fixedly connected with a plurality of isolation wire screens 8 A plurality of said isolated wire screens 8 are equidistantly fixedly connected on the outer wall of the winding shaft 7, and a plurality of said isolated ...

Embodiment 2

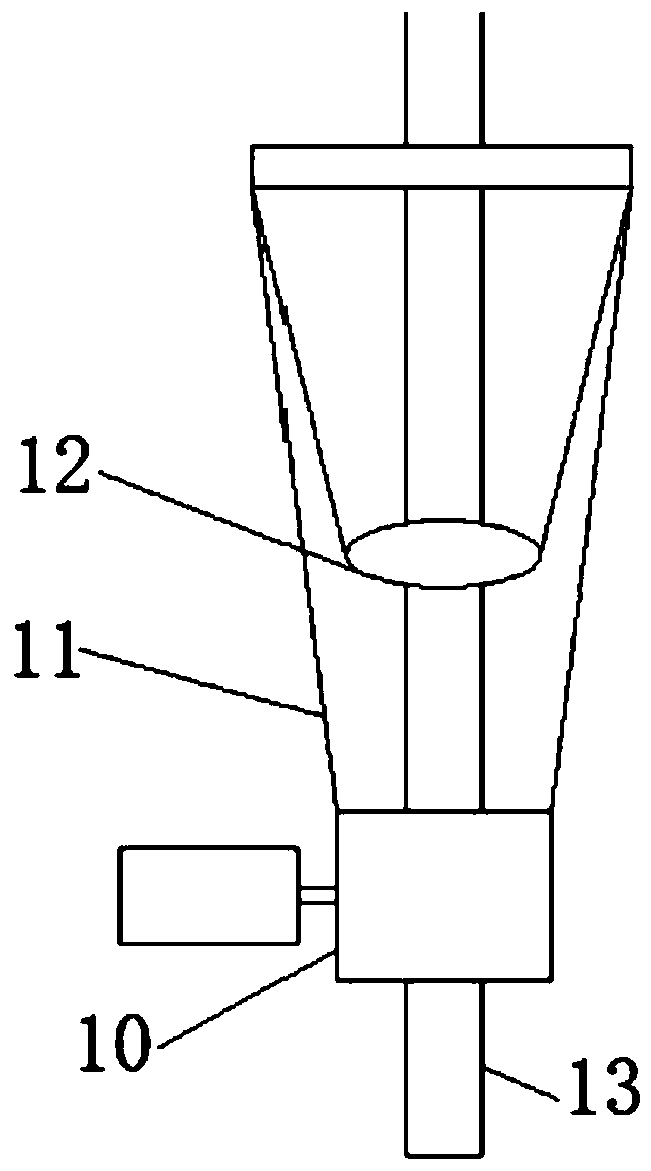

[0025] The electric hoisting device of the utility pole hoop provided in this embodiment is consistent with the embodiment 1, and only the locking method and the installation surface of the fixing ring are further limited.

[0026] An electric lifting device for a utility pole hoop, comprising a support frame 9, the end of the support frame 9 is fixedly connected with a fixed ring 5, a motor 2 is installed on the side wall of the support frame 9, and the output shaft of the motor 2 The end extends into the support frame 9, the outer wall of the output shaft of the motor 2 is fixedly connected with a pinion 3, the inner wall of the support frame 9 is rotatably connected with a winding shaft 6, and the outer wall of the winding shaft 6 is fixedly connected with a large gear 4. The pinion gear 3 and the bull gear 4 mesh with each other, and the outer wall of the winding shaft 6 is fixedly connected with a plurality of isolation wire screens 8, and the plurality of isolation wire s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap