Treatment equipment for polishing wastewater

A technology for treating equipment and wastewater, which is applied in ceramic wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as insufficient electrolysis, reduction, and interference of polishing wastewater filtration and treatment, so as to reduce the burden of manual cleaning, Uniform mixing reaction, effect enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

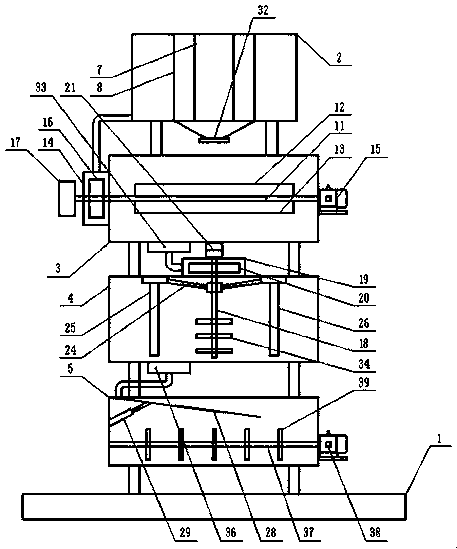

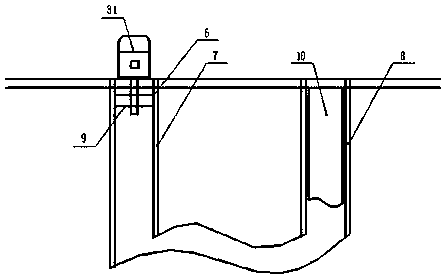

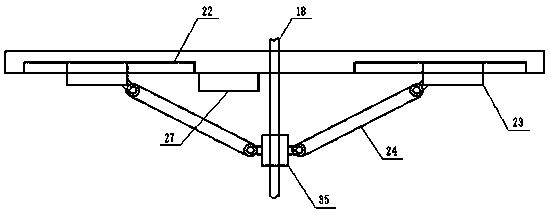

[0014] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 Now, a kind of polishing wastewater treatment equipment provided by the present invention is described, including a base 1 and an upper end of the base 1 and a filter box 2, a first electrolytic box 3, a second Electrolysis box 4 and reaction box 5, described filter box 2 is provided with filter assembly 6, and described filter assembly 6 comprises the first filter frame 7, the second filter frame 8 and the first filter frame 7 and the second filter frame 8 A transmission gear 9 and a scraper 10 are arranged between them, a first rotating shaft 11 is horizontally arranged on the middle side of the inner end of the first electrolytic box 3, and a first anode rod 12 and a first anode rod 12 are evenly arranged on the outside of the first rotating shaft 11. A cathode rod 13, the outer end of one side in the length direction of the first electrolytic box 3 is provided with a first drive housing 14, and the out...

Embodiment 2

[0015] Example 2: see figure 1 , figure 2 , a kind of polishing wastewater treatment equipment provided by the present invention is now described, the base 1, the filter box 2, the first electrolytic box 3, the second electrolytic box 4 and the reaction box 5 are respectively uniformly fixed with The vertical support column realizes the fixed connection, and the first filter frame 7 and the second filter frame 8 are both cylindrical frame bodies and the outer end walls are uniformly and densely provided with filter holes respectively, and the filter holes on the second filter frame 8 The diameter of the filter holes is smaller than the diameter of the filter holes on the first filter frame 7, and there is a set of upper annular grooves on the middle side of the inner top of the filter box 2, and the inner bottom of the filter box 2 corresponds to the The positions of the upper annular grooves are respectively provided with lower annular grooves, the diameter of the outer end o...

Embodiment 3

[0016] Embodiment 3: see figure 1 , image 3 Now, a kind of treatment equipment for polishing wastewater provided by the present invention will be described. One end of the first rotating shaft 11 in the longitudinal direction penetrates through the inner end wall of the first electrolytic tank 3 and protrudes, and the protruding end is connected by a coupling There is a first spare motor 15, the other end of the first rotating shaft 11 in the length direction runs through the inner end wall of the first electrolytic box 3, and the inner cavity of the first drive housing 14 protrudes, and the protruding end is connected to a The first power box 17, the first drive housing 14 and the first guide vane 16 are evenly arranged on the outside of the first rotating shaft 11, and the inner cavity at the bottom of the filter box 2 is connected to the filter box 2 through a pipe. The inner cavity at the upper end of the first driving housing 14 is connected, the inner cavity at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com