A method for extracting silver from metallurgical waste liquid

A waste liquid and metallurgical technology, which is applied in the field of gold smelting waste liquid treatment, can solve the problems such as silver element is not easy to extract, and achieve the effects of less auxiliary materials, zero discharge cycle and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

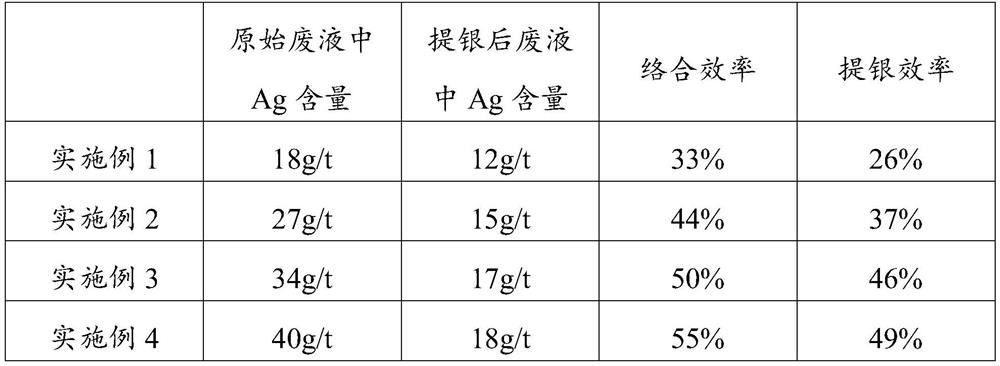

Examples

Embodiment 1

[0015] A method for extracting silver from metallurgical waste liquid, comprising the steps of:

[0016] 1) Leave the acidic waste liquid after metallurgy to stand, take the supernatant, heat and concentrate just after precipitation, and set aside;

[0017] 2) Take 15 denier nylon 6 fiber, cut it to 5mm, put it into a DMSO solution of sodium hydroxide, the mass ratio of sodium hydroxide to DMSO is 1.5:1, and stir at a constant speed at 60°C for 30 minutes;

[0018] 3) drip the solution obtained in step 2) into the concentrated solution obtained in step 1) dropwise, stop the dripping when the pH of the mixed solution is 6, filter after standing for 5 days, and obtain the complexed nylon staple fiber and filtrate, and combine the filtrate with Step 1) The acidic waste liquid after metallurgy used is mixed and recycled;

[0019] 4) Put the complexed nylon staple fiber obtained in step 3) into 10wt% hydrochloric acid, control the mass ratio of the complexed nylon staple fiber to ...

Embodiment 2

[0021] A method for extracting silver from metallurgical waste liquid, comprising the steps of:

[0022] 1) Leave the acidic waste liquid after metallurgy to stand, take the supernatant, heat and concentrate just after precipitation, and set aside;

[0023] 2) Take 20 denier nylon 56 fiber, cut it to 10mm, put it into a DMSO solution of sodium hydroxide, the mass ratio of sodium hydroxide to DMSO is 1:1, and stir at a constant speed at 65°C for 25 minutes;

[0024] 3) drip the solution obtained in step 2) into the concentrated solution obtained in step 1) dropwise, stop the dripping when the pH of the mixed solution is 6, filter after standing for 4 days, and obtain the complexed nylon staple fiber and filtrate, and combine the filtrate with Step 1) The acidic waste liquid after metallurgy used is mixed and recycled;

[0025] 4) Put the complexed nylon staple fiber obtained in step 3) into 7wt% hydrochloric acid, control the mass ratio of the complexed nylon staple fiber to h...

Embodiment 3

[0027] A method for extracting silver from metallurgical waste liquid, comprising the steps of:

[0028] 1) Leave the acidic waste liquid after metallurgy to stand, take the supernatant, heat and concentrate just after precipitation, and set aside;

[0029] 2) Take 5 denier nylon 6 fiber, cut it to 10mm, put it into a DMSO solution of sodium hydroxide, the mass ratio of sodium hydroxide to DMSO is 1.5:1, and stir at a constant speed at 70°C for 20 minutes;

[0030] 3) drip the solution obtained in step 2) into the concentrated solution obtained in step 1) dropwise, stop the dripping when the pH of the mixed solution is 6, filter after standing for 3 days, and obtain the complexed nylon staple fiber and filtrate, and combine the filtrate with Step 1) The acidic waste liquid after metallurgy used is mixed and recycled;

[0031] 4) Put the complexed nylon staple fiber obtained in step 3) into 5wt% hydrochloric acid, control the mass ratio of the complexed nylon staple fiber to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com