Garbage suction system and sweeper truck with same

A technology for suction system and garbage, which is applied in the field of garbage suction system and road sweeper, which can solve the problems of high accident risk of operators, waste of fan power, leakage of garbage, etc., and achieve simple operation of fan speed adjustment and reduce The effect of human operation and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

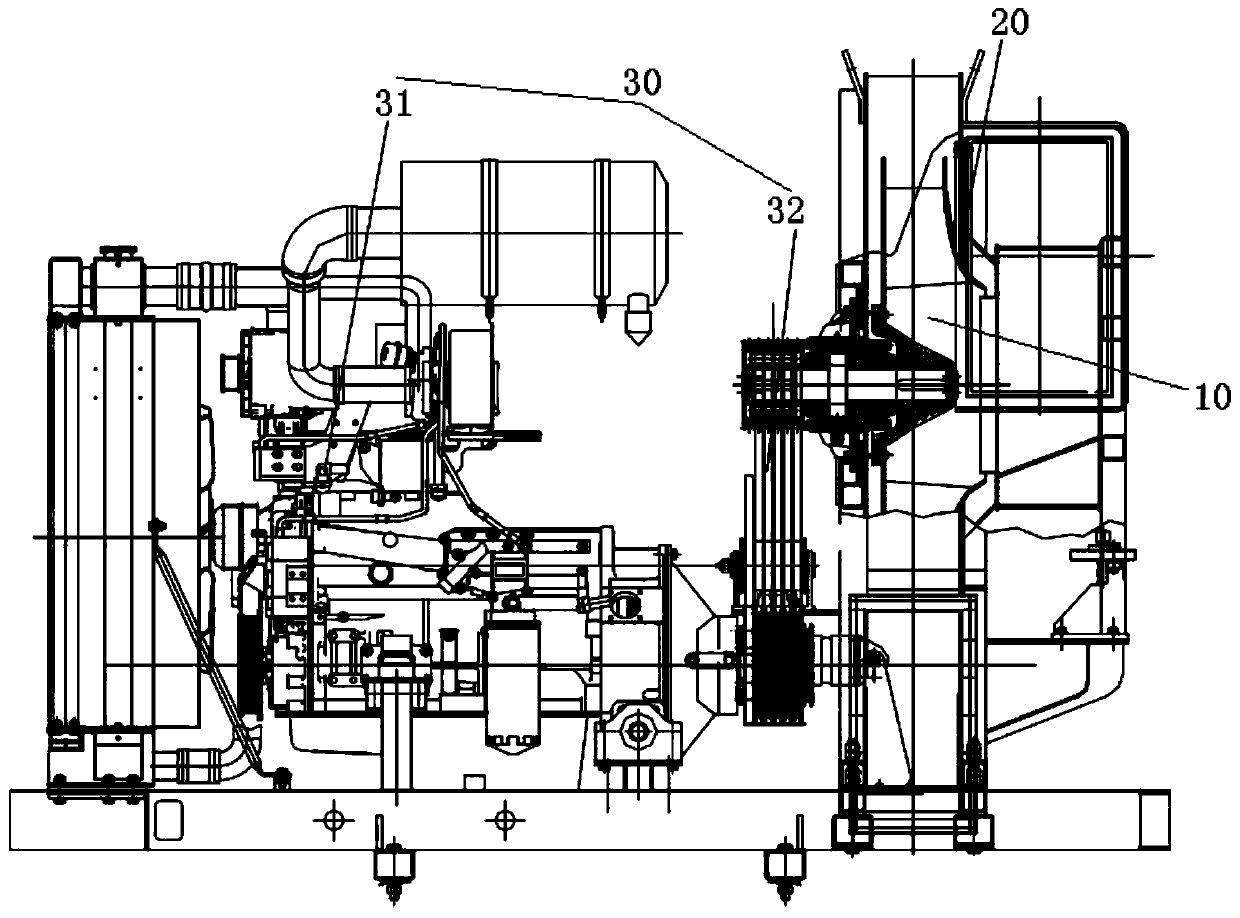

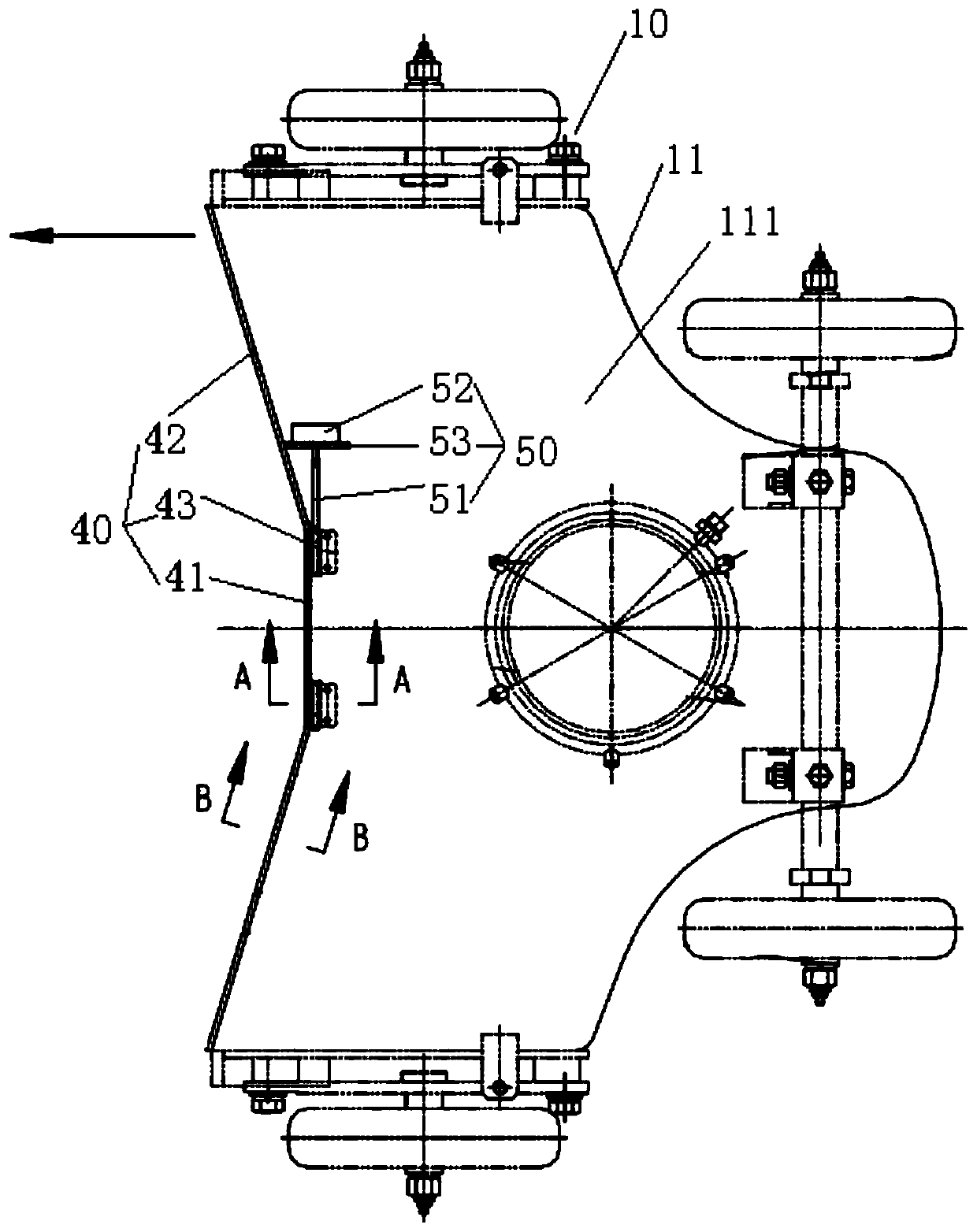

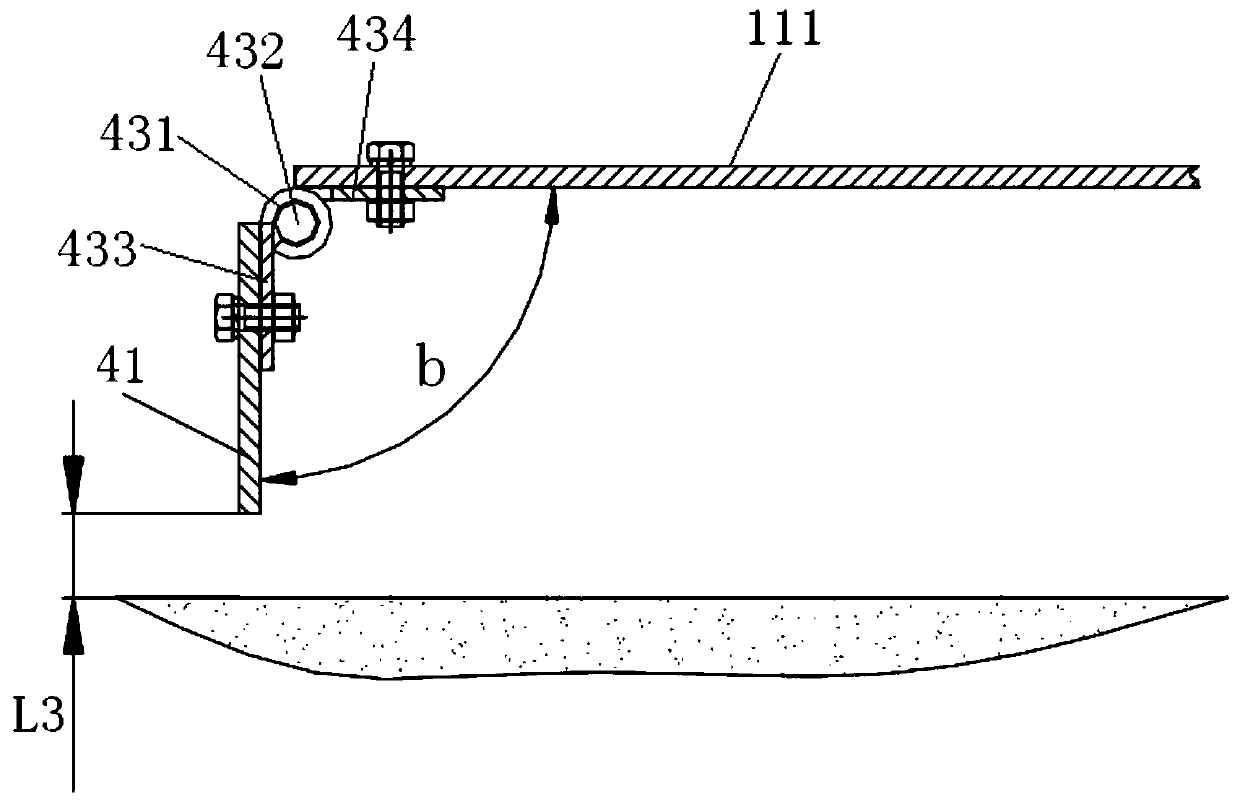

[0028] refer to figure 1 with figure 2 , the preferred embodiment of the present invention provides a garbage suction system, comprising: a suction nozzle assembly 10 for sucking road surface garbage, the inlet 11 of the suction nozzle assembly 10 faces the road surface, and the outlet of the suction nozzle assembly 10 The feed port is connected with a traction fan 20 for generating negative pressure in the suction nozzle assembly 10 to absorb road rubbish. The traction fan 20 is connected with a drive adjustment device 30 for driving its rotation and adjusting its speed. The drive adjustment device 30 is connected to a useful A control device (not shown) for controlling its action. The feed side of the feed port 11 of the suction nozzle assembly 10 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com