Fully-embedded steel beam combined floor slab and construction method thereof

A technology for combining floor slabs and construction methods, which is applied in the directions of slabs, buildings, building components, etc., can solve the problems of large thickness of composite slabs, weak connection between concrete and steel bars, etc., achieves low self-weight of slabs, eliminates hidden dangers of welding quality, and improves stress. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

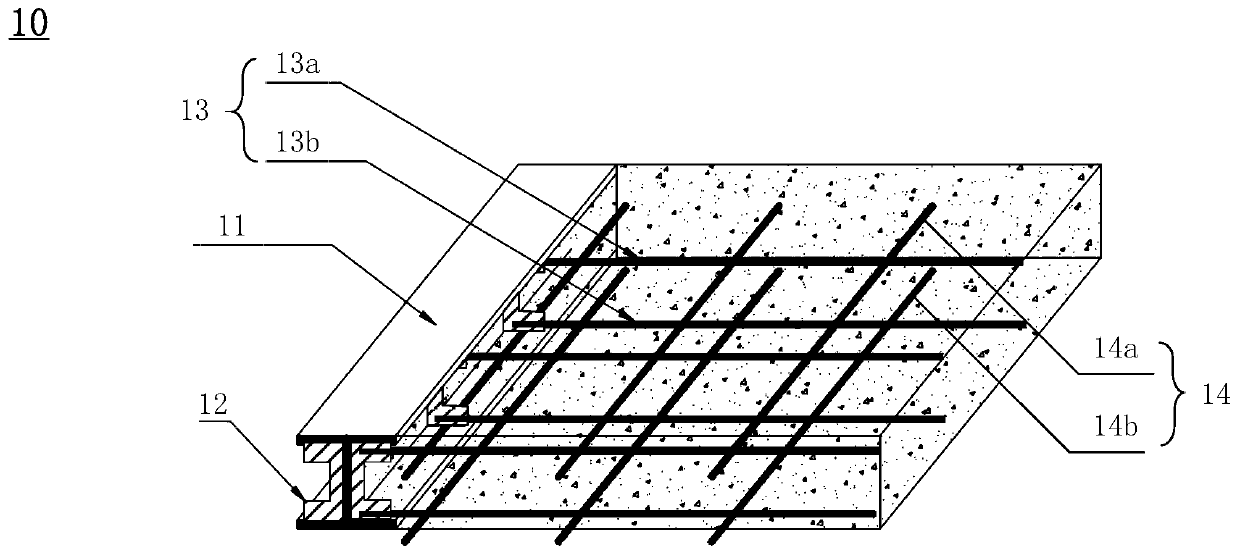

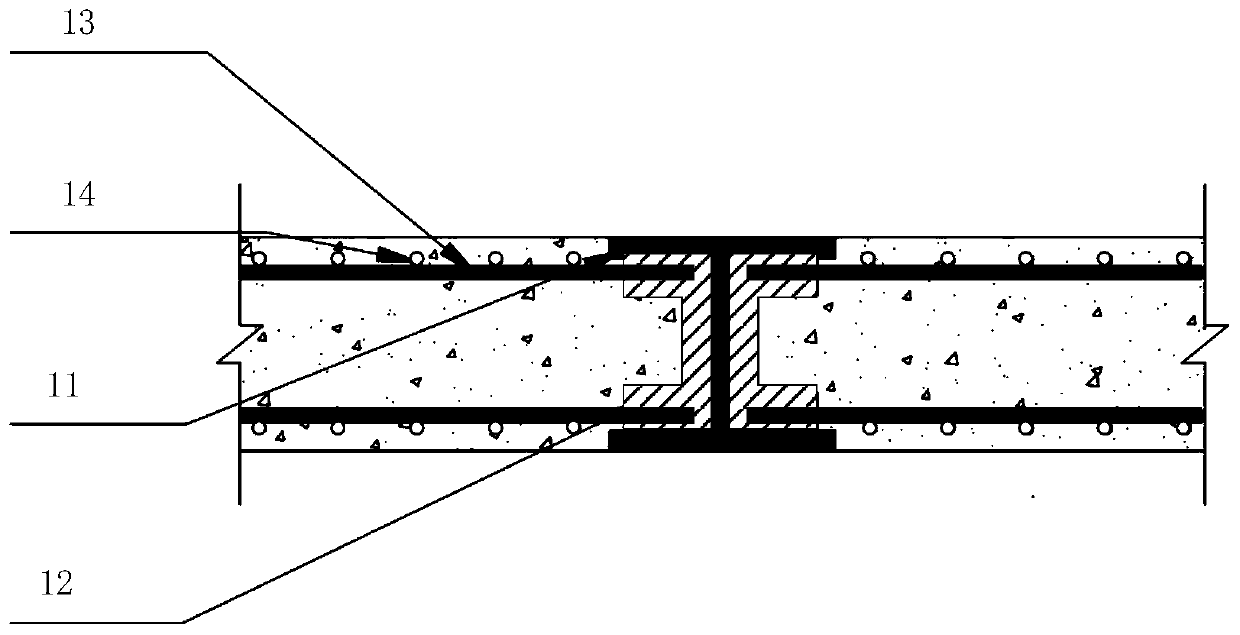

[0042] Please refer to figure 1 and figure 2 , which is a schematic structural diagram of a fully embedded steel beam composite floor slab according to Embodiment 1 of the present invention. Such as figure 1 and figure 2 As shown, the fully embedded steel beam composite floor 10 includes: floor steel beams 11, C-shaped stiffeners 12, stressed steel bars 13, distributed steel bars 14 and concrete layers 15; the floor steel beams 11 have at least one C-shaped groove, the C-shaped groove extends along the length direction of the floor steel beam 11; the stressed steel bar 13 is fixedly connected with the C-shaped stiffener 12, and the C-shaped stiffener 12 is The floor steel beams 11 are arranged in the C-shaped groove at intervals in the length direction, and are fixedly connected with the C-shaped groove; the stressed steel bars 13 are arranged crosswise with the distributed steel bars 14, and the concrete layer 15 is poured On the stressed steel bar 13 and the distribute...

Embodiment 2

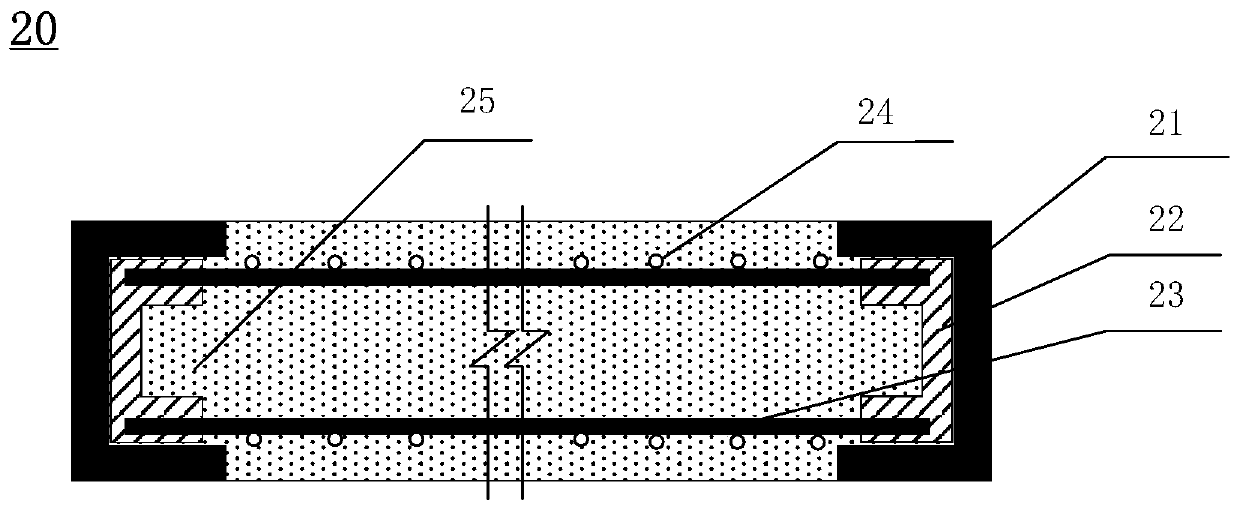

[0068] Please refer to image 3 , which is a side view of a fully embedded steel beam composite floor slab according to Embodiment 2 of the present invention. Such as image 3 As shown, the fully embedded steel beam composite floor 20 includes: floor steel beams 21, C-shaped stiffeners 22, stressed steel bars 23, distributed steel bars 24 and concrete layers 25; the floor steel beams 21 have at least one C-shaped groove, the C-shaped groove extends along the length direction of the floor steel beam 21; the stressed steel bar 23 is fixedly connected with the C-shaped stiffener 22, and the C-shaped stiffener 22 is The floor steel beams 21 are arranged in the C-shaped groove at intervals in the length direction, and are fixedly connected with the C-shaped groove; the stressed steel bars 23 are arranged crosswise with the distributed steel bars 24, and the concrete layer 25 is poured On the stressed steel bar 23 and the distributed steel bar 24.

[0069] Specifically, the floor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com