A method of forced lowering of the hard roof in the center of the working face

A hard roof and working face technology, applied in ground mining, earth drilling, mining equipment, etc., can solve problems such as high pressure on the central roof, achieve the effects of reducing stress, maintaining integrity, and enhancing blasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

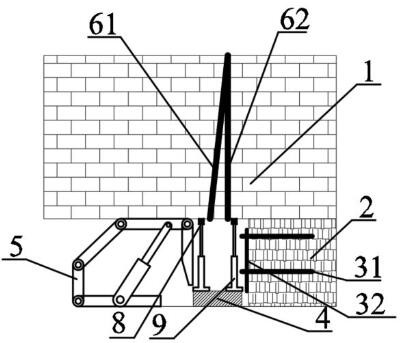

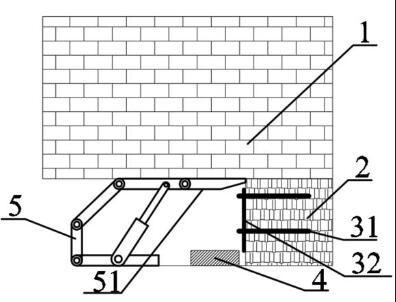

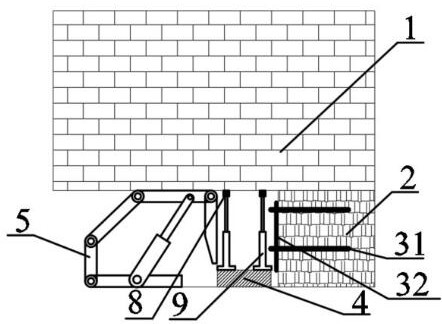

[0037] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0038] Refer to attached Figure 1-6, the present invention is achieved through the following technical solutions, a method for forced caving of a hard roof in the center of a working face, comprising the following steps:

[0039] a, when mining to the center of the working face, the side guard plate 51 of the fully mechanized mining support 5 protrudes toward the front end of the coal seam mining, and pushes to the top plate 1, and constructs several glass fiber reinforced plastic anchor rods 31 inserted into the coal seam 2 from the front end of the coal seam mining along the mining direction, And use resin anchoring agent for anchoring. There are two glass fiber reinforced plastic anchor rods 31 in the height direction, which are arranged vertically, in the height direction and in the mining direction, and the distance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com