Aluminum wood composite profile

A composite profile, aluminum-wood technology, applied in the direction of building elements, connecting components, friction-clamped detachable fasteners, etc., can solve problems such as high requirements for clips, easy release of screws, and easy shaking of wooden substrates. Achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

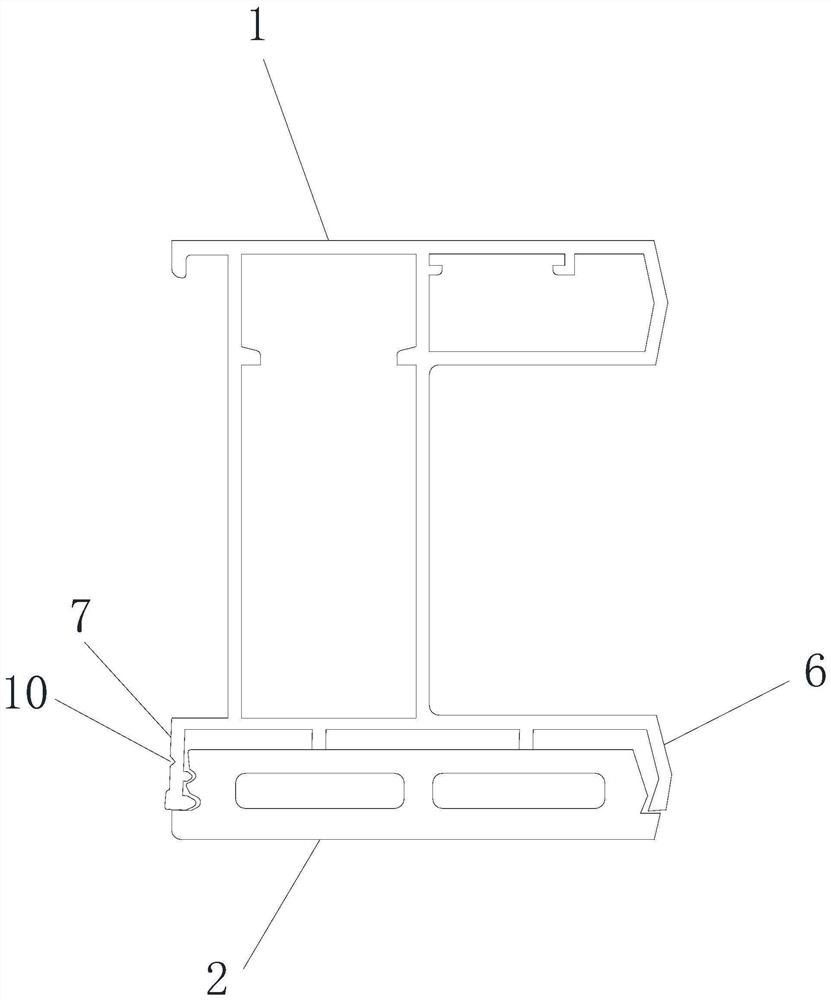

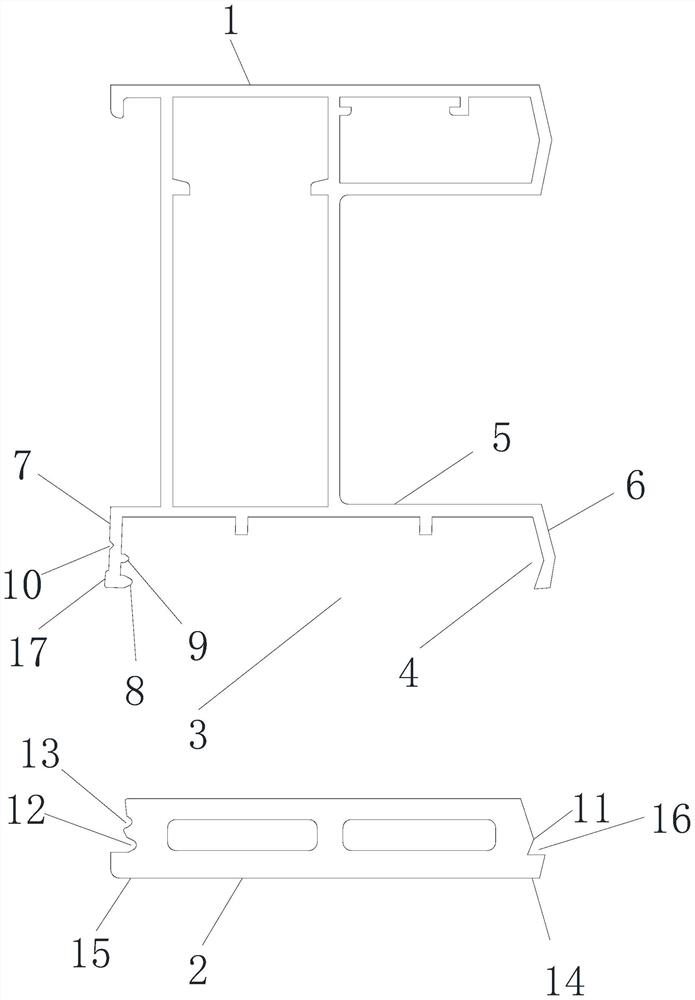

[0022] Embodiment 1, the present invention provides an aluminum-wood composite profile, see figure 1 and figure 2 , including an aluminum substrate 1 and a wooden substrate 2, the aluminum substrate is provided with a groove 3 for accommodating the wooden substrate, the groove is composed of a bottom plate 5, a first side plate 6 and a second side Surrounded by a plate 7, the first side plate is provided with a first bend 4 bent inward, and the inner side of the second side plate is provided with a first protrusion 8 and a second protrusion 9, the The first protrusion is located at the end of the second side plate that is not connected to the bottom plate; the second protrusion is located in the groove and has a distance from the first protrusion; the second protrusion The length of the protrusion is less than the length of the first protrusion; the outer side of the second side plate is provided with a notch 10; one side of the wooden base material is provided with an outwa...

Embodiment 2

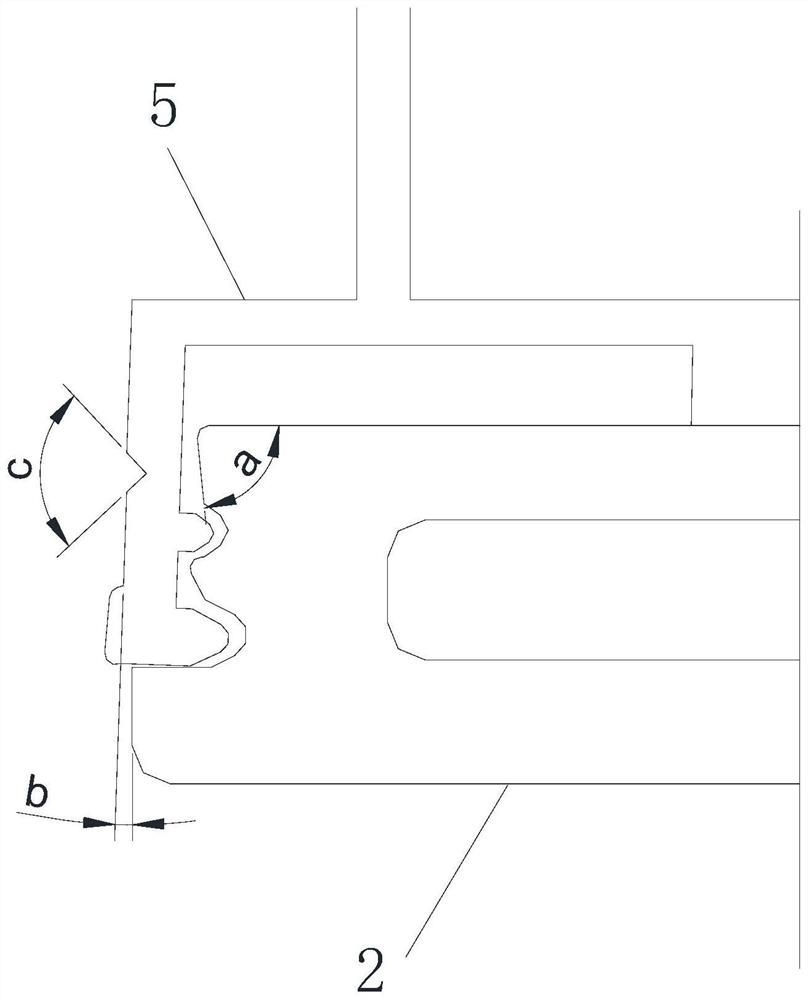

[0028] Embodiment 2, embodiment 2 is the further improvement that is done on the basis of embodiment 1, see Figure 1-Figure 3 , the end of the wooden base material away from the bottom plate extends to both sides to form a first extension 14 and a second extension 15, and an inner concave corner 16 is formed between the first extension and the outer convex corner, the The end bent away from the bottom plate can be stuck in the inner concave corner; the outer surface of the first extension part is flush with the end of the bottom plate close to the first extension part, and the outer surface of the second extension part It is flush with the other end of the bottom plate; the outer surface of the second side plate is provided with a bump 17 corresponding to the position of the first protrusion, and the outer edge of the bump is relative to the second side plate. The outer surface is inclined, and one end close to the second extension part is located outside the other end. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com