Industrial temperature adjusting device

A temperature adjustment device and an industrial technology, applied in the field of adjustment devices and temperature adjustment devices, can solve the problems of easy splashing of water droplets, inconvenient maintenance, easy blockage, etc., and achieve the effects of convenient maintenance, easy extraction and cleaning, and reduced pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

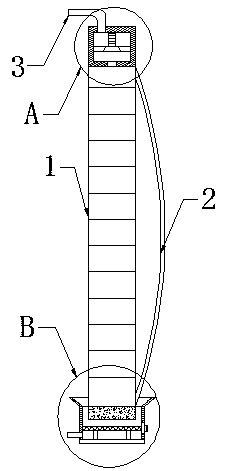

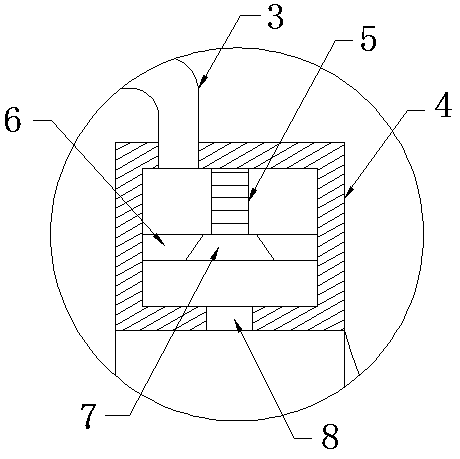

[0026] Such as Figure 1-Figure 2 As shown, the cooling pad main body 1 is included, the top of the cooling pad main body 1 is fixedly connected with a water inlet mechanism, the three side walls of the cooling pad main body 1 are fixedly connected with a metal frame 9, and the bottom of the cooling pad main body 1 is provided with a collection mechanism, and the water inlet The mechanism includes a strip-shaped water inlet box 4 and a lifting plate 7. The bottom end of the strip-shaped water inlet box 4 is fixedly connected to the top of the wet curtain body 1, and the middle part of the inner wall on both sides of the strip-shaped water inlet box 4 is fixedly connected with side plates 6. , the lifting plate 7 is placed between the two side plates 6, the middle part of the strip-shaped water inlet tank 4 bottoms is dug with a water outlet 8, and the both sides of the lifting plate 7 top are fixedly connected with tension springs 5, and the tension springs 5 The top is fixedl...

Embodiment 2

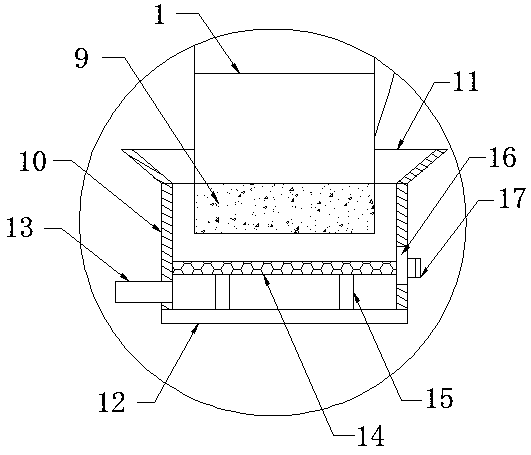

[0028] On the basis of Example 1, such as Figure 3-Figure 5 As shown, the collection mechanism includes a collection box 10 and a bottom plate 12, the bottom of the wet curtain main body 1 is placed inside the collection box 10, the bottom of the metal frame 9 is fixedly connected with the inner wall of the collection box 10, and the top of the collection box 10 is fixedly connected with a guide. Water board 11, the middle part of collecting box 10 inside is movable to be provided with filter screen 14, and the bottom end of collecting box 10 is snapped connected with the top of base plate 12, and both sides of base plate 12 tops are all fixedly connected with support column 15, and the bottom of collecting box 10 A mounting plate 16 is movably embedded in the front, and a water outlet pipe 13 is fixedly embedded in the middle of the back of the collection box 10. One side wall of the mounting plate 16 is fixedly connected to one side of the filter screen 14, and the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com