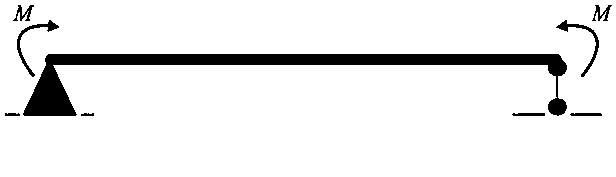

Structure bending moment measuring device under pure bending condition

A measuring device, pure bending technology, applied in the direction of measuring device, using stable bending force to test material strength, using stable torsion to test material strength, etc., can solve the problem of discontinuous bending moment measurement, inaccurate load application, and Single measurement structure and other problems, to achieve the effect of compact structure, simple operation, and multiple measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific operation of the device will be described in further detail below in conjunction with the structural drawings.

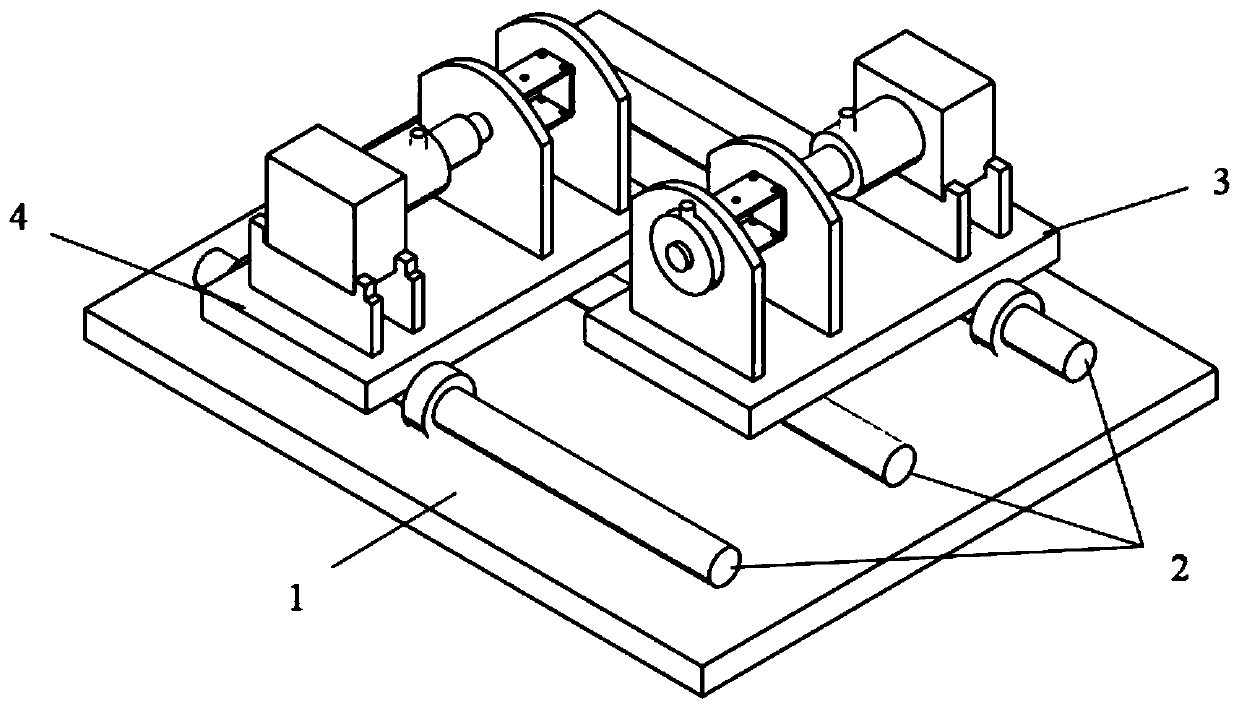

[0023] Figure 5 It is a top view of the device, which includes a horizontal base (1), a guide rail (2), an active end bending moment measuring device (3) and a driven end bending moment measuring device (4).

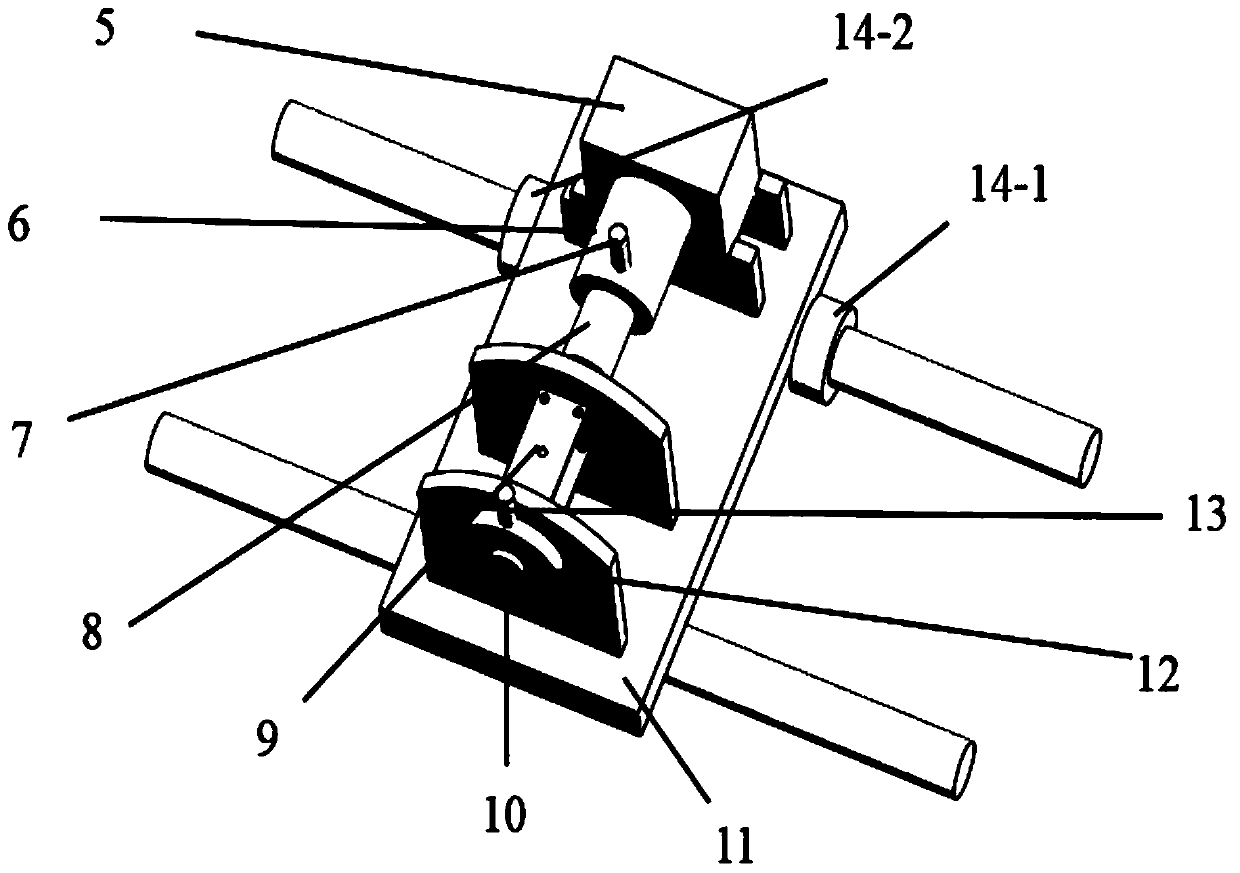

[0024] The active end bending moment measuring device and the driven end bending moment measuring device have the same components and structure. Take the active end as an example: the device includes: active end drive motor (5), active end reducer (6), active end first jack (7), active end torque sensor (8), active end adjustable clamp (9) ), active end rotating shaft (10), active end fixing frame (11), active end angle control panel (12), active end second top wire (13), active end first buckle (14-1), active end The second buckle (14-2) at the end. The installation process of this device is as follows: first assemble the driving and driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com