A heat cycle resistant enameled wire and its production process

An enameled wire, heat-resistant technology, used in cables, insulated conductors, conductors, etc., can solve the problems of enameled wire performance is not stable enough, performance is not stable enough, chemical stability is weak, etc., to improve the overall strength and service life, the quality of finished products The effect of improving, improving mechanical strength and overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

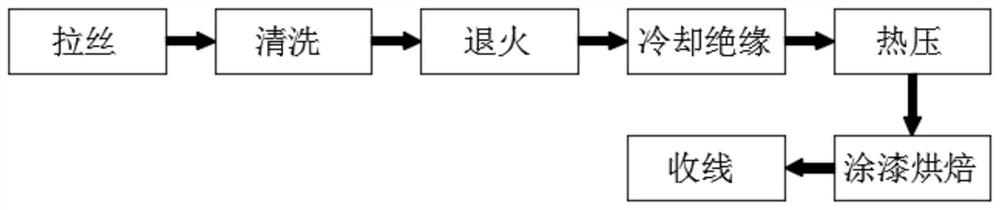

[0046] Such as image 3 and Figure 4 , a heat-resistant cycle enameled wire production process, comprising the following steps:

[0047] A: wire drawing, the raw material is pure copper, determine the size of the copper raw material, detect the burrs on the copper surface, keep the copper surface smooth and free of cracks, and then draw the raw material copper, and stretch the raw material at a speed of 800m / min;

[0048] B: Cleaning, clean the copper wire after wire drawing, remove the oil stain on the surface of the copper wire, check whether the surface of the copper wire is smooth and flat, and keep the copper wire level;

[0049] C: Annealing, put the cleaned copper wire into the annealing furnace, the temperature of the annealing furnace is 480°C, and improve the mechanical properties of the copper wire through heat treatment on the copper wire;

[0050] D: cooling and insulation, take the copper wire out of the annealing furnace to cool the copper wire, the copper wi...

Embodiment 2

[0055] A heat-resistant cycle enameled wire production process, comprising the following steps:

[0056] A: wire drawing, the raw material is pure copper, determine the size of the copper raw material, detect the burrs on the copper surface, keep the copper surface smooth and free of cracks, and then draw the raw material copper, and stretch the raw material at a speed of 850m / min;

[0057] B: Cleaning, clean the copper wire after wire drawing, remove the oil stain on the surface of the copper wire, check whether the surface of the copper wire is smooth and flat, and keep the copper wire level;

[0058]C: annealing, put the cleaned copper wire into an annealing furnace, and improve the mechanical properties of the copper wire by heat-treating the copper wire, the temperature of the annealing furnace is 550°C;

[0059] D: cooling and insulation, take the copper wire out of the annealing furnace to cool the copper wire, the copper wire taken out of the annealing furnace is natur...

Embodiment 3

[0064] A heat-resistant cycle enameled wire production process, comprising the following steps:

[0065] A: Wire drawing, the raw material is pure copper, determine the size of the copper raw material, detect the burrs on the copper surface, keep the copper surface smooth and free of cracks, and then draw the raw copper, and stretch the raw material at a speed of 950m / min;

[0066] B: Cleaning, clean the copper wire after wire drawing, remove the oil stain on the surface of the copper wire, check whether the surface of the copper wire is smooth and flat, and keep the copper wire level;

[0067] C: Annealing, put the cleaned copper wire into the annealing furnace, the temperature of the annealing furnace is 680°C, and improve the mechanical properties of the copper wire through heat treatment on the copper wire;

[0068] D: cooling and insulation, take the copper wire out of the annealing furnace to cool the copper wire, the copper wire taken out of the annealing furnace is nat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com