Glue filling, curing and stripping tooling method of battery module

A battery module and filling technology, applied in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc., can solve the problem of increasing the weight of the battery compartment, reducing the battery mass energy density, and reducing the maintainability of the battery management system and other problems, to achieve the effect of improving maintainability, reducing scrap rate, and reducing operating weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

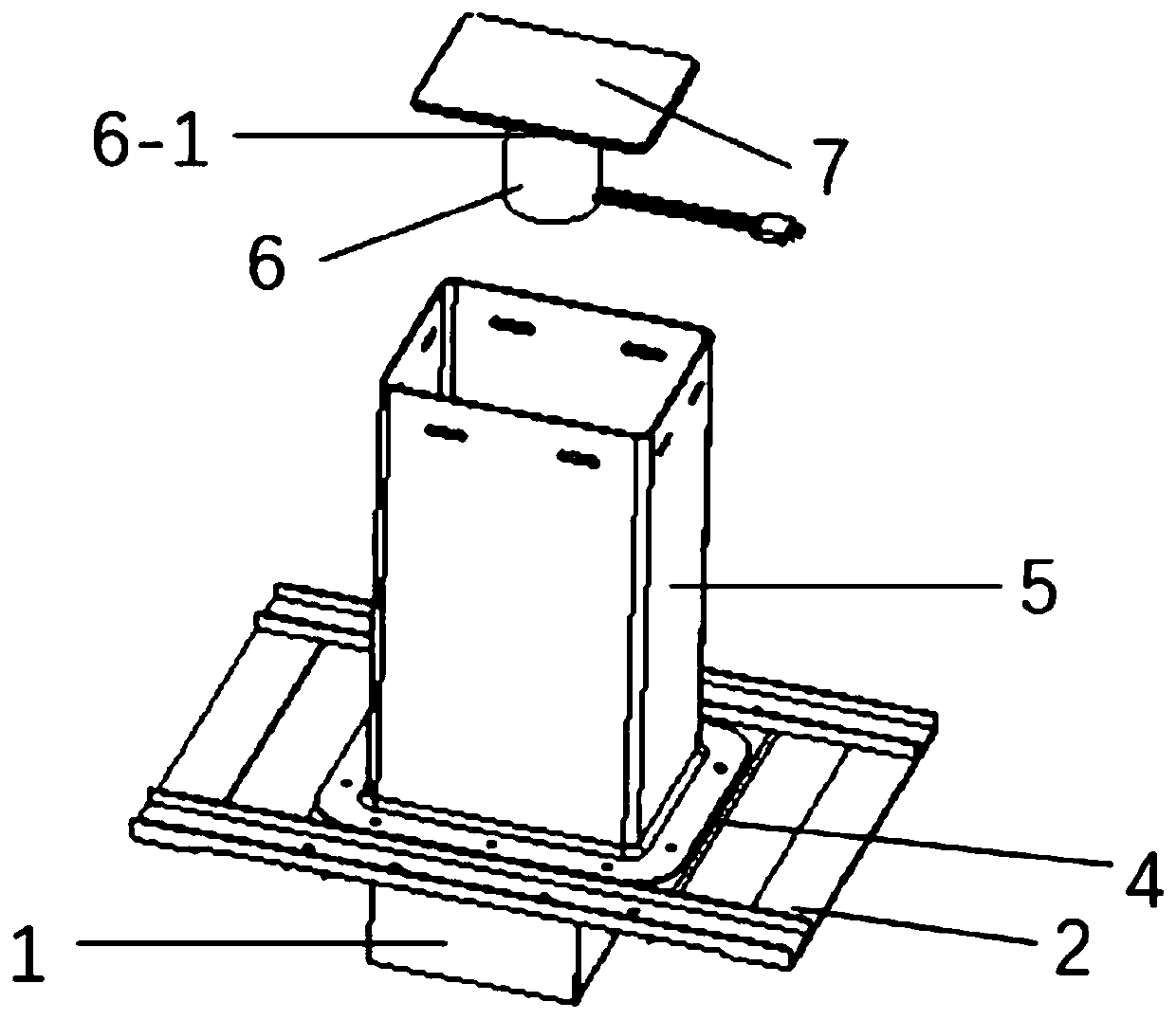

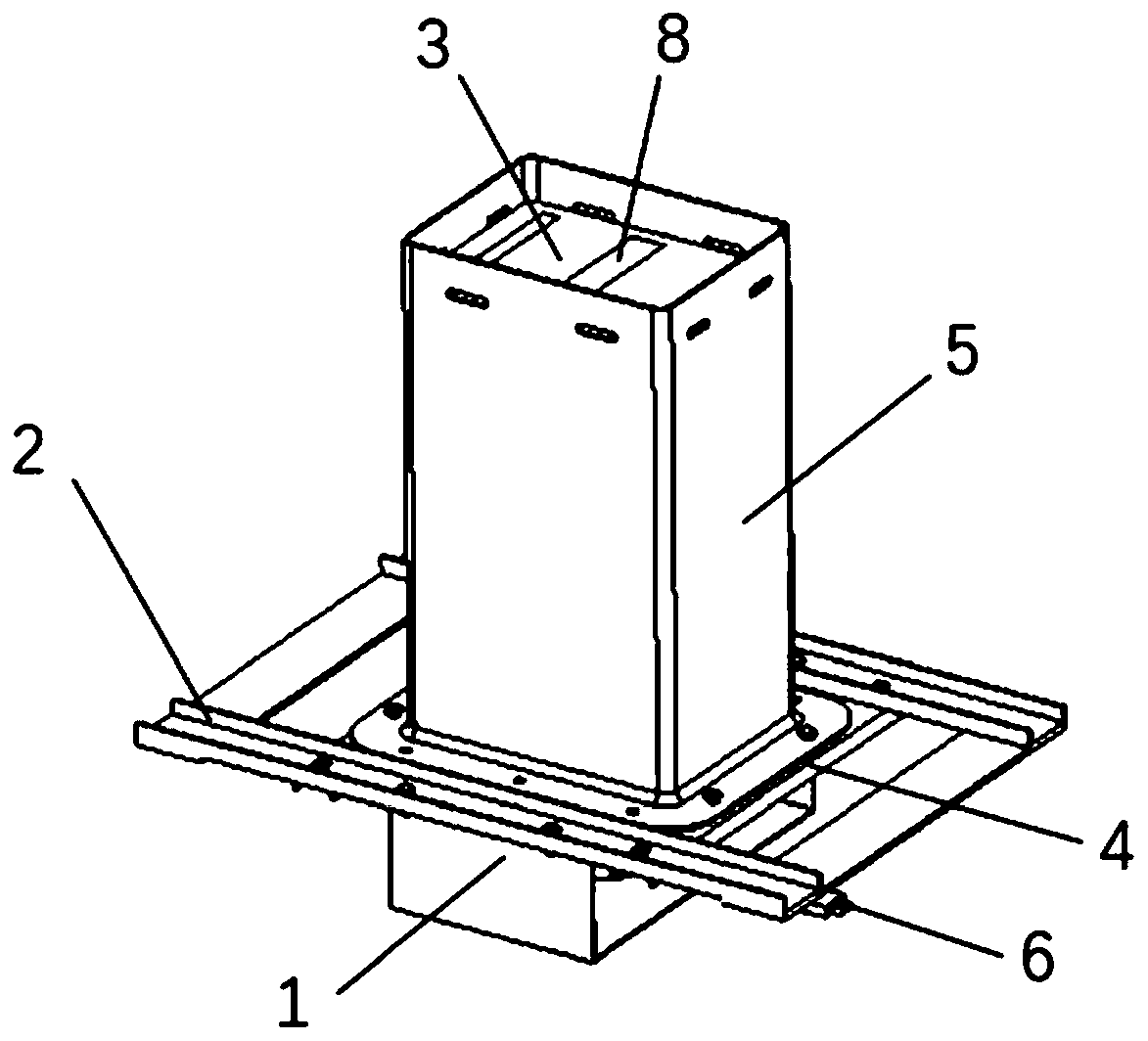

[0031] A battery module, the battery module includes a support mechanism, a filling mechanism and a module 3, the top of the support mechanism is fastened with a filling mechanism, and the filling mechanism is loaded with the module 3.

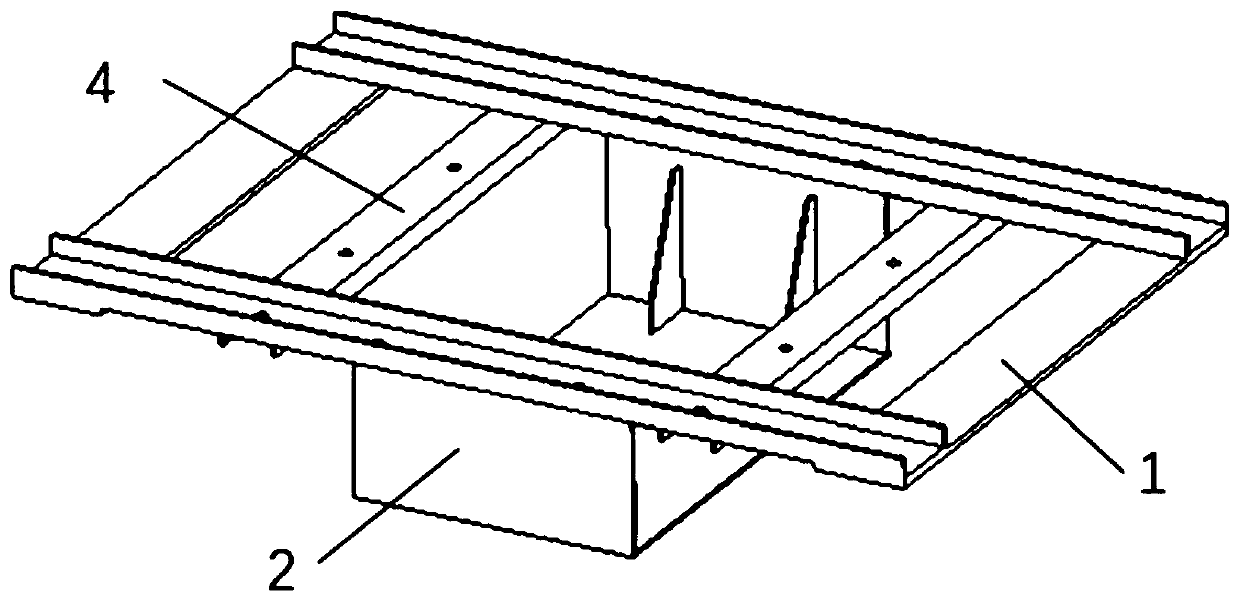

[0032] Further, the support mechanism includes a support base 1, a ring beam 2 and a cross beam 4, the support base 1 is fixedly connected to the ring beam 2 by bolts, the cross beam 4 is arranged in parallel on the ring beam 2, and the ring beam 2 is connected by bolts. Fix the connecting beam 4.

[0033] Further, the filling mechanism includes a filling barrel 5, a push plate hydraulic cylinder 6 and a silicone pad 7, the filling barrel 5 is fastened by bolts and set on the crossbeam 4, and the back of the push plate hydraulic cylinder 6 is provided with a silicone rubber pad. Pad 7, the push plate hydraulic cylinder 6 and the silica gel pad 7 are put into the bottom of the filling barrel 5;

[0034] The area of push plate 6-1 is less tha...

Embodiment 2

[0047] Using the above-mentioned glue-filling, curing and stripping tooling method for a battery module, the method includes the following steps:

[0048] Step 1: Install the supporting mechanism;

[0049] Step 2: Fix the canning barrel 5 on the beam 4 through bolts;

[0050] Step 3: Attach the hydraulic cylinder 6 with the push plate to the back of the push plate 6-1 with a silicone pad with adhesive backing;

[0051] Step 4: Extend the hydraulic cylinder to the longest height, and put the hydraulic cylinder 6 with the push plate into the bottom of the canning barrel 5;

[0052] Step 5: Slowly press the module 3 into the canning barrel 5, and place it at the center of the canning barrel 5;

[0053] Step 6: Slowly pour the potting glue into the canning barrel 5 to form the glue layer 8;

[0054] Step 7: Adjust the indoor temperature to 55°C and let it stand for 25 minutes to cure the adhesive layer;

[0055] Step 8: Adjust the indoor temperature to 15°C again, let it stand...

Embodiment 3

[0057] Using the above-mentioned glue-filling, curing and stripping tooling method for a battery module, the method includes the following steps:

[0058] Step 1: Install the supporting mechanism;

[0059] Step 2: Fix the canning barrel 5 on the beam 4 through bolts;

[0060] Step 3: Attach the hydraulic cylinder 6 with the push plate to the back of the push plate 6-1 with a silicone pad with adhesive backing;

[0061] Step 4: Extend the hydraulic cylinder to the longest height, and put the hydraulic cylinder 6 with the push plate into the bottom of the canning barrel 5;

[0062] Step 5: Slowly press the module 3 into the canning barrel 5, and place it at the center of the canning barrel 5;

[0063] Step 6: Slowly pour the potting glue into the canning barrel 5 to form the glue layer 8;

[0064] Step 7: Adjust the indoor temperature to 50°C and let it stand for 30 minutes to cure the adhesive layer;

[0065] Step 8: Adjust the indoor temperature to 10°C again, let it stand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of linear thermal expansion | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com