Through-wall porcelain bushing joint sheath

A porcelain sleeve and sheath technology, which is applied in the field of through-wall porcelain sleeve joint sheath, can solve the problem that the sealing performance of the insulating protection box cannot meet the actual application requirements, and achieves preventing exposure, increasing service life, and improving sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

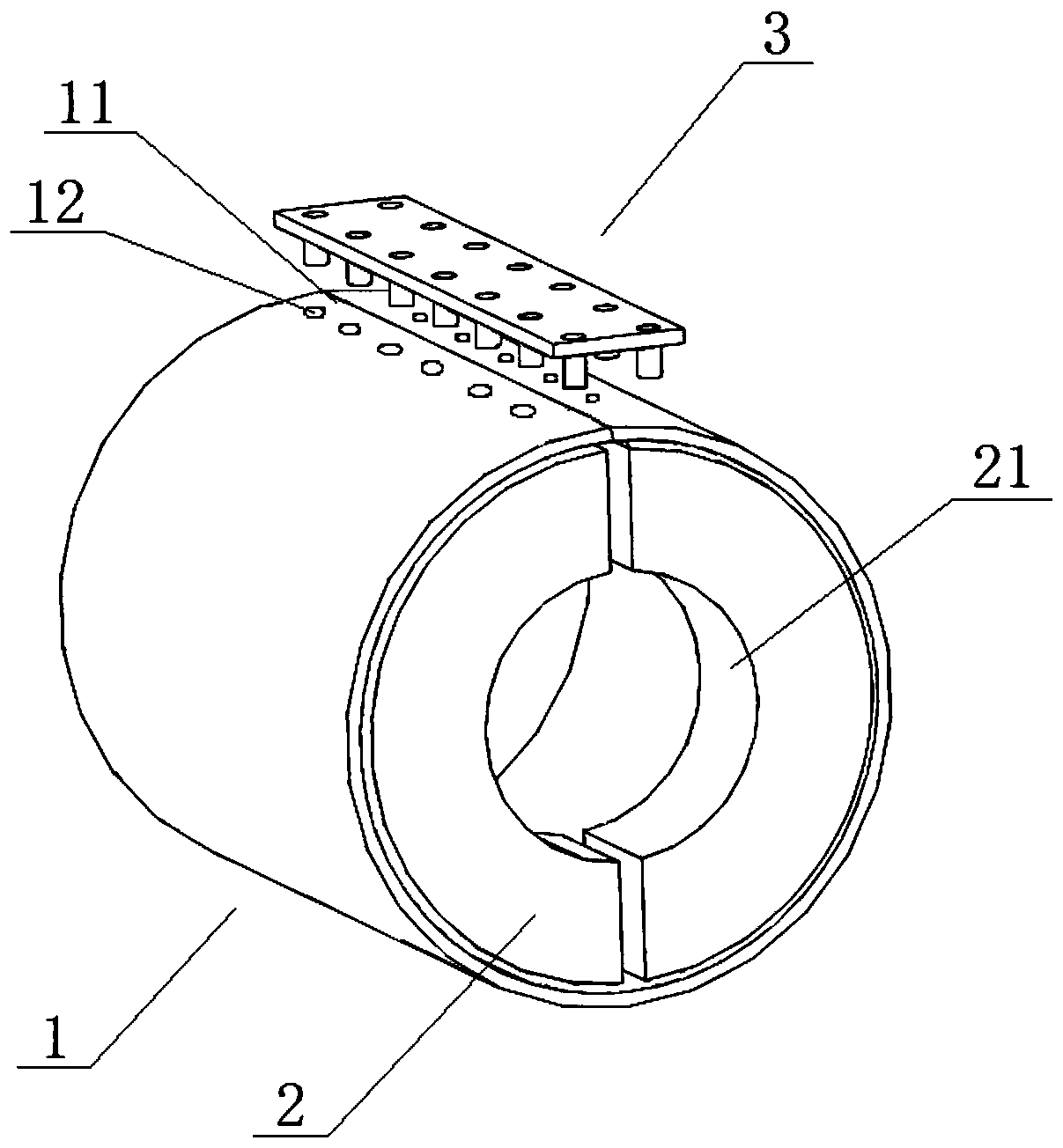

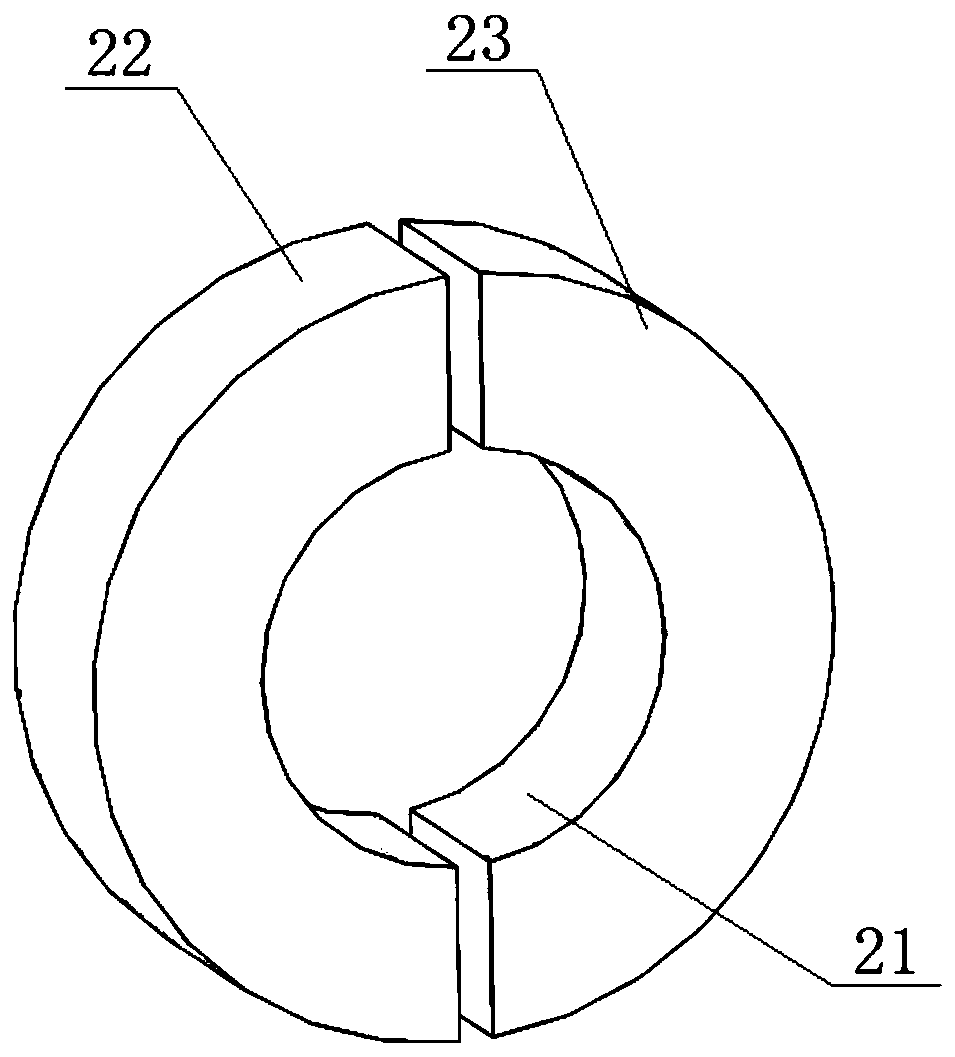

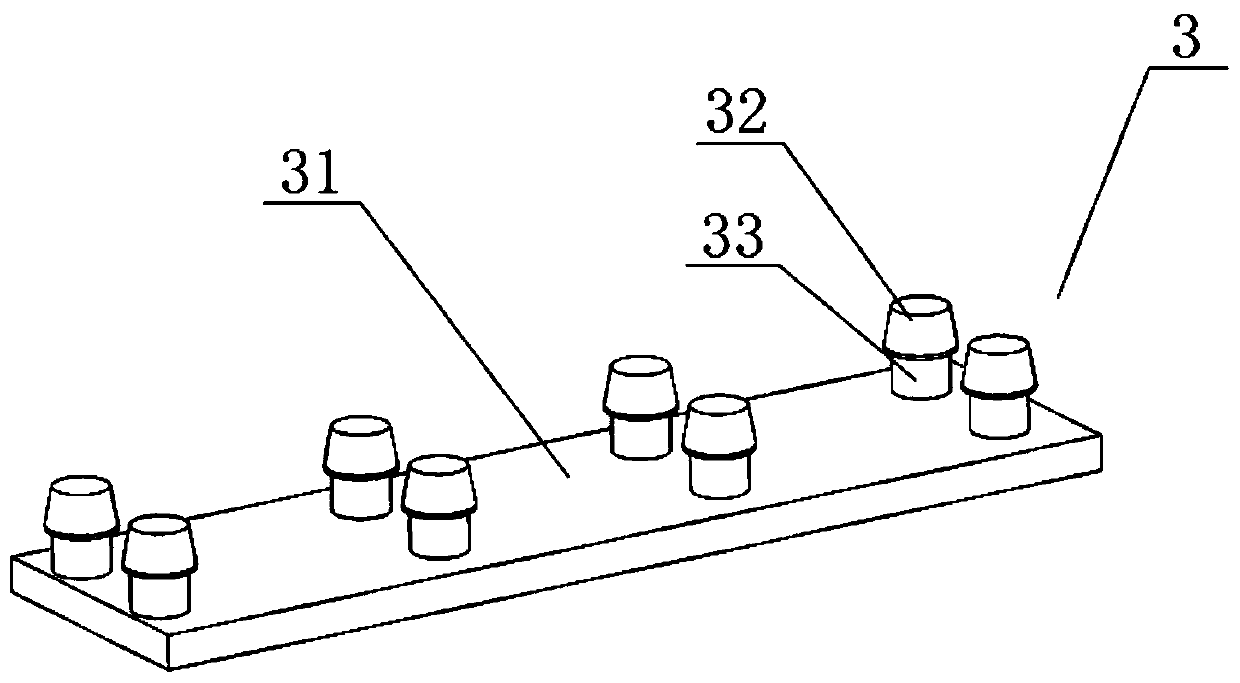

[0028] Such as Figure 1 to Figure 3 Shown is the first embodiment of a wall-through porcelain bushing joint sheath of the present invention, including a sleeve body 1, one end of the sleeve body 1 is detachably connected to a sealing structure 2, and the sealing structure 2 is provided with a pipe-shaped The opening structure 21 through which the busbar passes.

[0029] The main body of the sleeve 1 is used to wrap the through-wall porcelain bushing joint, prevent the wall-through porcelain bushing joint from being exposed, and avoid the occurrence of thermal ablation accidents caused by corrosion of the connection position of the bus bridge; the sealing structure 2 can improve the protection of the through-wall porcelain bushing joint. The sealing performance of the sleeve; the setting of the opening structure 21 can facilitate the passage of the tubular busbar, so that the sheath of the through-wall porcelain bushing joint can be adapted to the joint.

[0030] In addition,...

Embodiment 2

[0043] This embodiment is similar to Embodiment 1, the difference is that in this embodiment, if Figure 1 to Figure 3 As shown, the sleeve main body 1 is a rubber sleeve. The sealing structure 2 is a rubber sealing structure. The arrangement of the rubber sleeve and the rubber sealing structure can improve the aging resistance and acid and alkali resistance of the sleeve main body 1 and the sealing structure 2, and increase the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com