A compact and efficient cooling motor

A cooling motor with a compact structure, which is applied in the direction of cooling/ventilation device, magnetic circuit shape/style/structure, electromechanical device, etc. It can solve the problems that the water channel cannot be disassembled and repaired, the structure of the water-cooled motor is complex, and the volume of the motor becomes larger. Achieve good cooling effect, easy disassembly and assembly, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

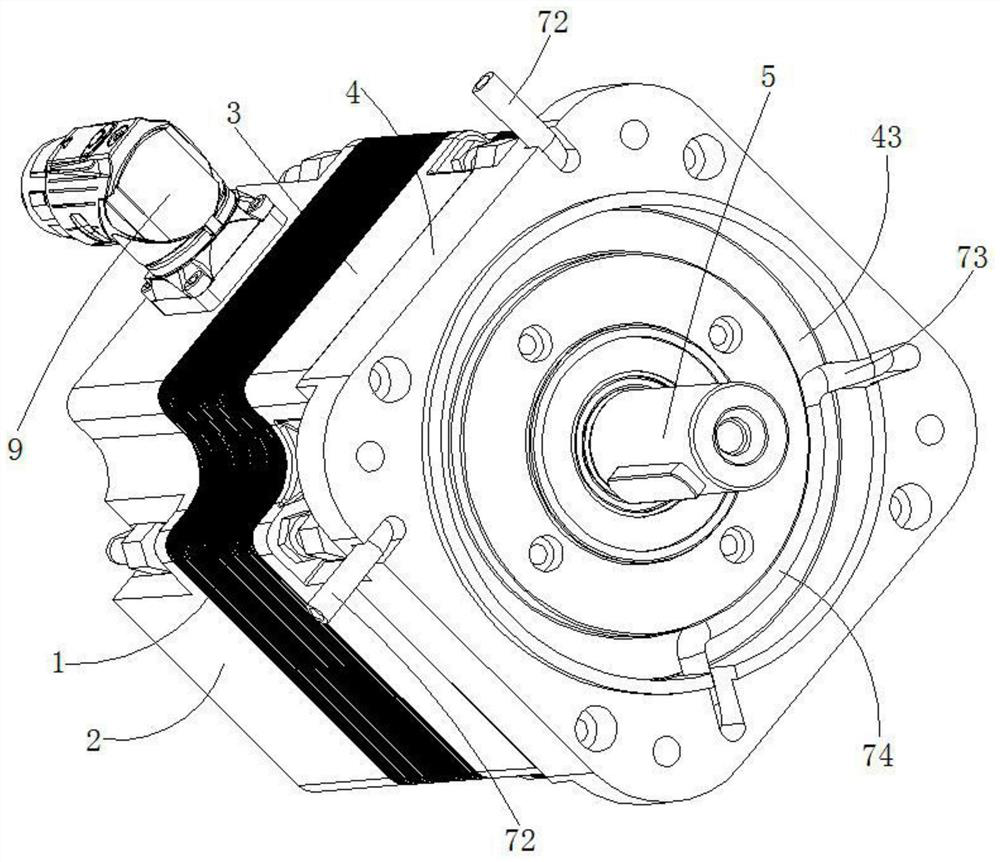

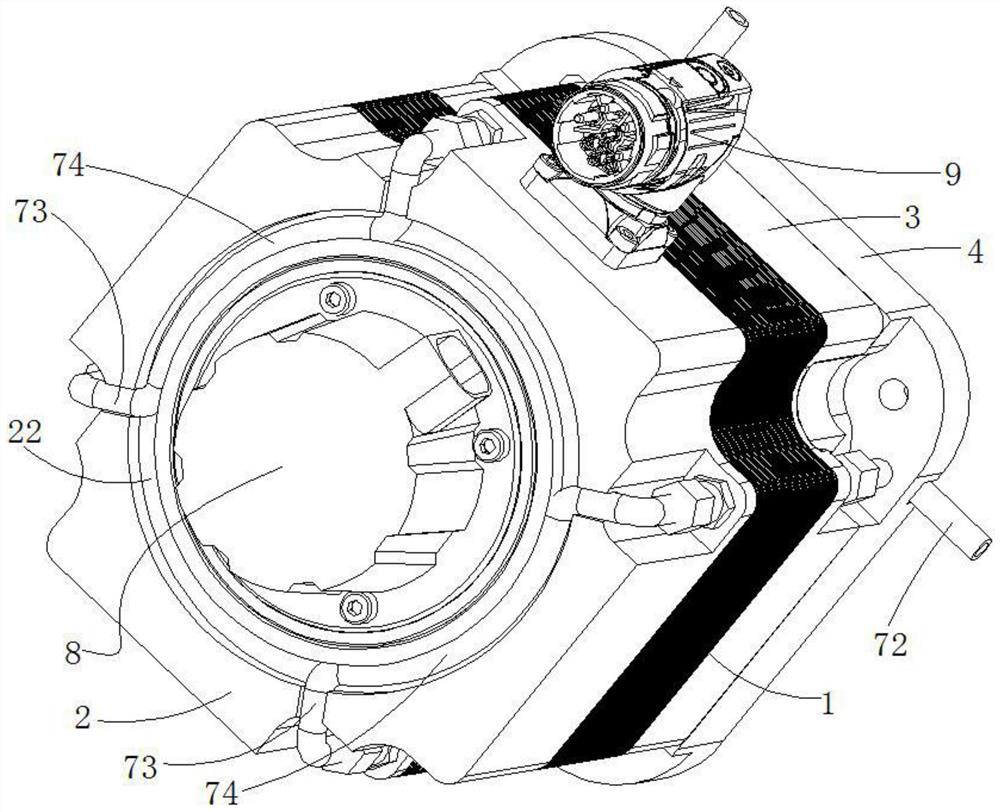

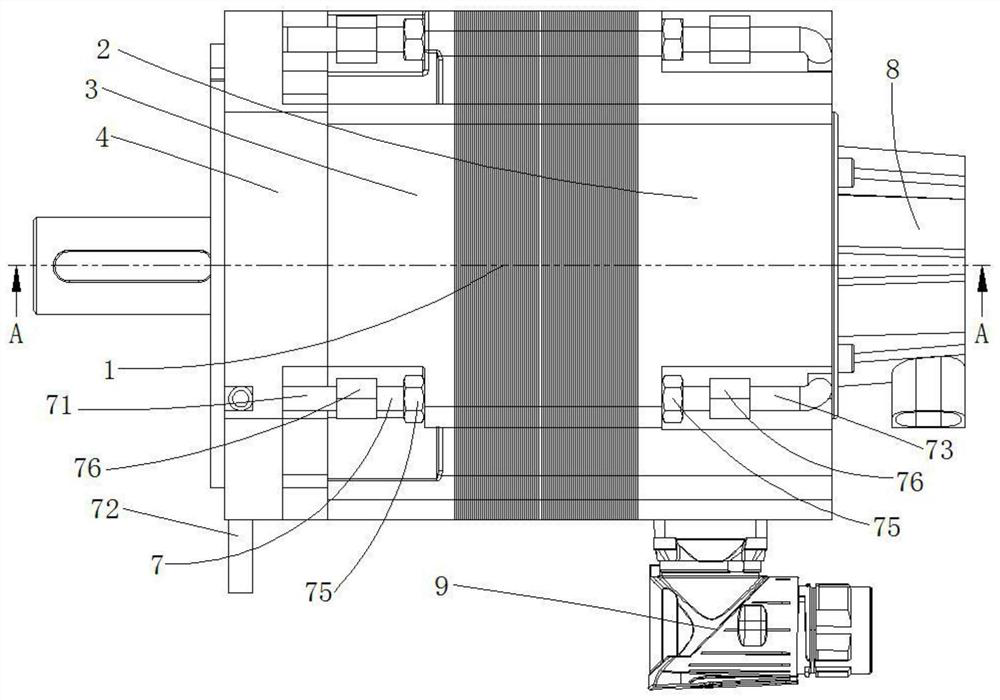

[0028] Such as Figure 1 to Figure 10 As shown, a compact and highly efficient cooling motor, including connecting end cover 4, front end cover 3, stator core 1 and rear end cover 2, which are installed sequentially from front to back, wherein connecting end cover 4 and front end cover 3 pass through screw connection.

[0029] The stator core 1 is provided with a stator winding 12, and the outer periphery of the stator core 1 is wrapped and sealed by epoxy potting glue. , the outer wall of the rotating shaft 5 is interference-fitted with a rotor core 51, the outer wall of the rotor core 51 is fitted with a magnetic steel 52, and an air gap is formed between the inner wall of the stator core 1 and the magnetic steel 52, These are the existing technologies of the motor, and will not be introduced in detail here.

[0030] A front bearing 6 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com