DC bias calibration device and method of zero intermediate frequency waveform generation system

A waveform generation and DC bias technology, applied in the field of signal processing, can solve problems such as increasing costs, and achieve the effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

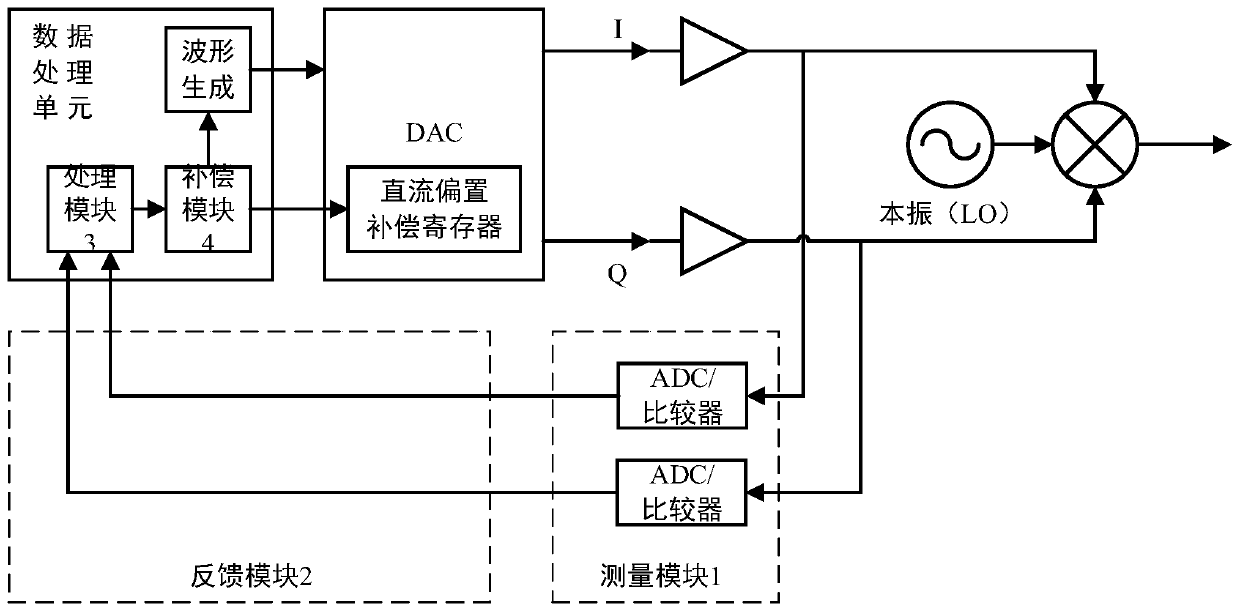

[0049] combined with figure 1 , the present embodiment proposes a DC offset calibration device for a zero-IF waveform generation system, which includes a measurement module 1, a feedback module 2, a processing module 3 and a compensation module 4, which respectively measure, feed back, and Processing and Compensation.

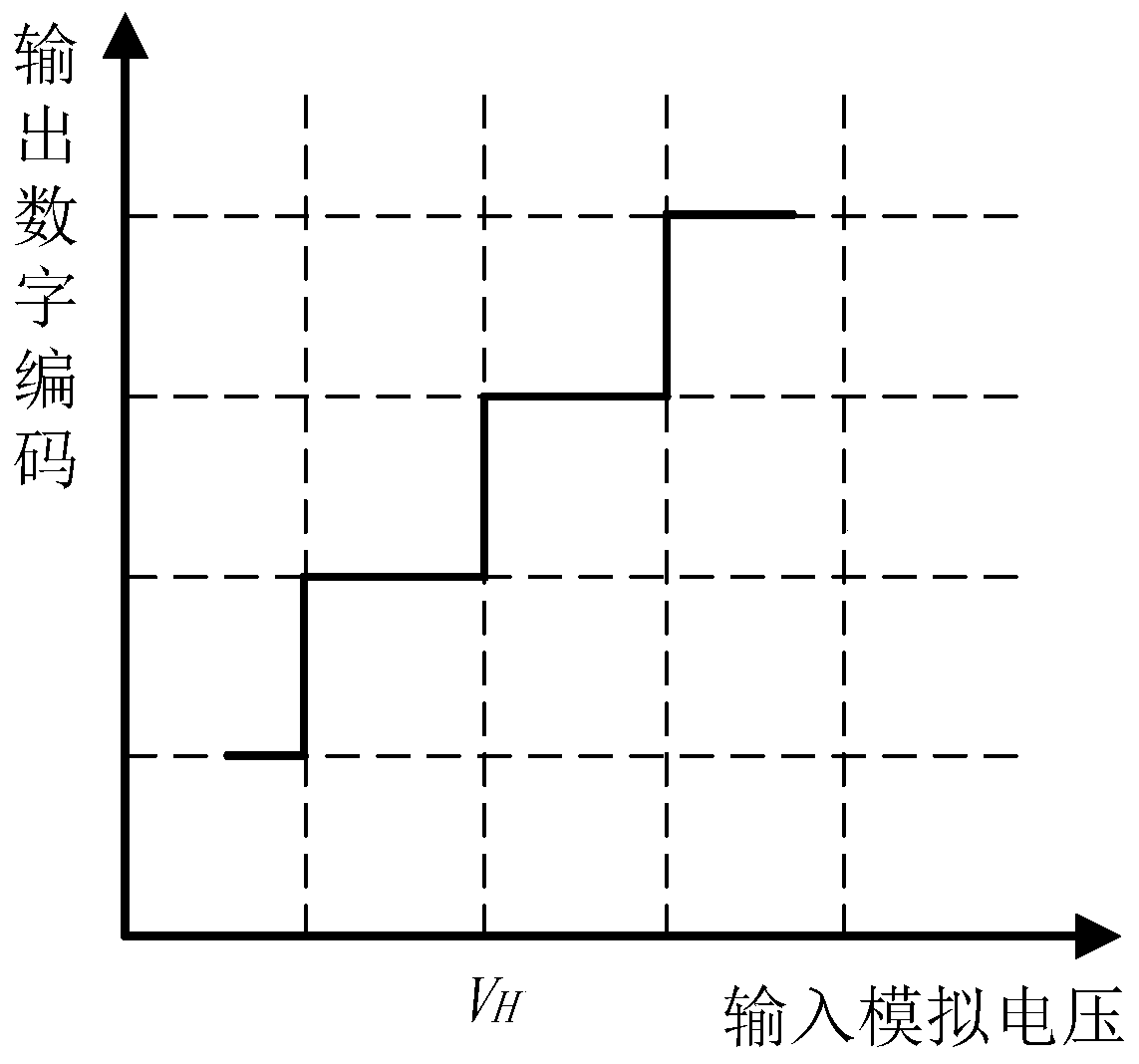

[0050] The measurement module 1 involved is used to measure the voltage amplitude of the output waveform signal of the zero-IF waveform generation system, and quantize the measurement result into digital data, whose quantization digits are much smaller than the digits of the DAC on the output channel of the zero-IF waveform generation system. During specific implementation, the number of quantization bits of the measurement module 1 may be a 1-bit AD converter or a 1-bit comparator.

[0051] The feedback module 2 is connected to the measurement module 1 and used to feed back the measurement results to the data processing unit of the zero-IF waveform generation...

Embodiment 2

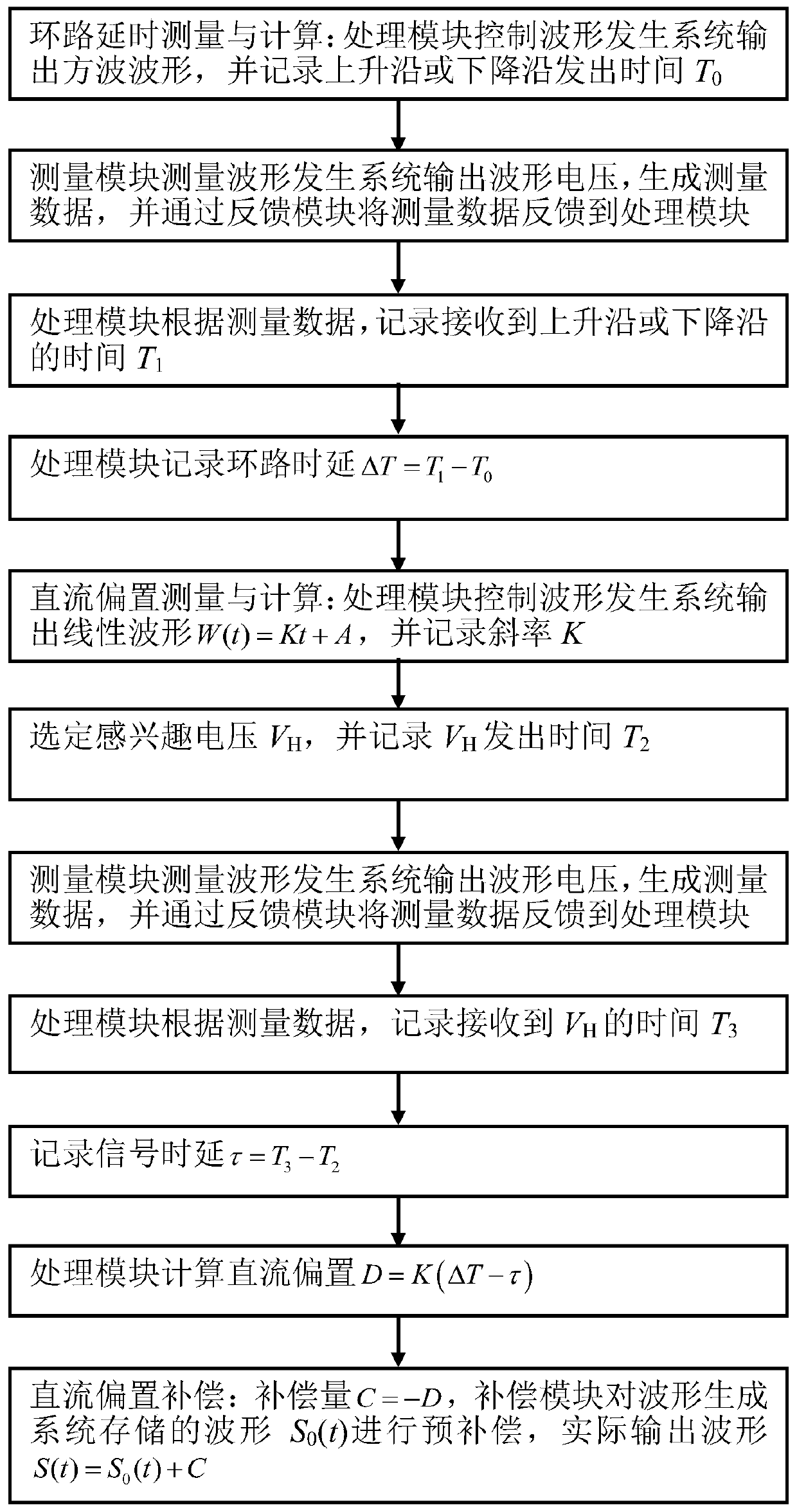

[0056] Based on the DC offset calibration device of Embodiment 1, combined with the attached figure 2 , this embodiment provides a DC offset calibration method for a zero-IF waveform generation system, and its implementation process includes:

[0057] 1) Loop delay measurement and calculation:

[0058] 1.1) The processing module 3 controls the waveform generation system to output a square wave waveform, and records the rising or falling edge sending time T 0 ;

[0059] 1.2) The measurement module 1 measures the output waveform voltage of the waveform generation system, generates measurement data, and feeds back the measurement data to the processing module 3 through the feedback module 2;

[0060] 1.3) The processing module 3 records the time T of receiving the rising edge or the falling edge according to the measurement data 1 ;

[0061] 1.4) Processing module 3 records loop time delay ΔT=T 1 -T 0 .

[0062] 2) DC bias measurement and calculation:

[0063] 2.1) The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com