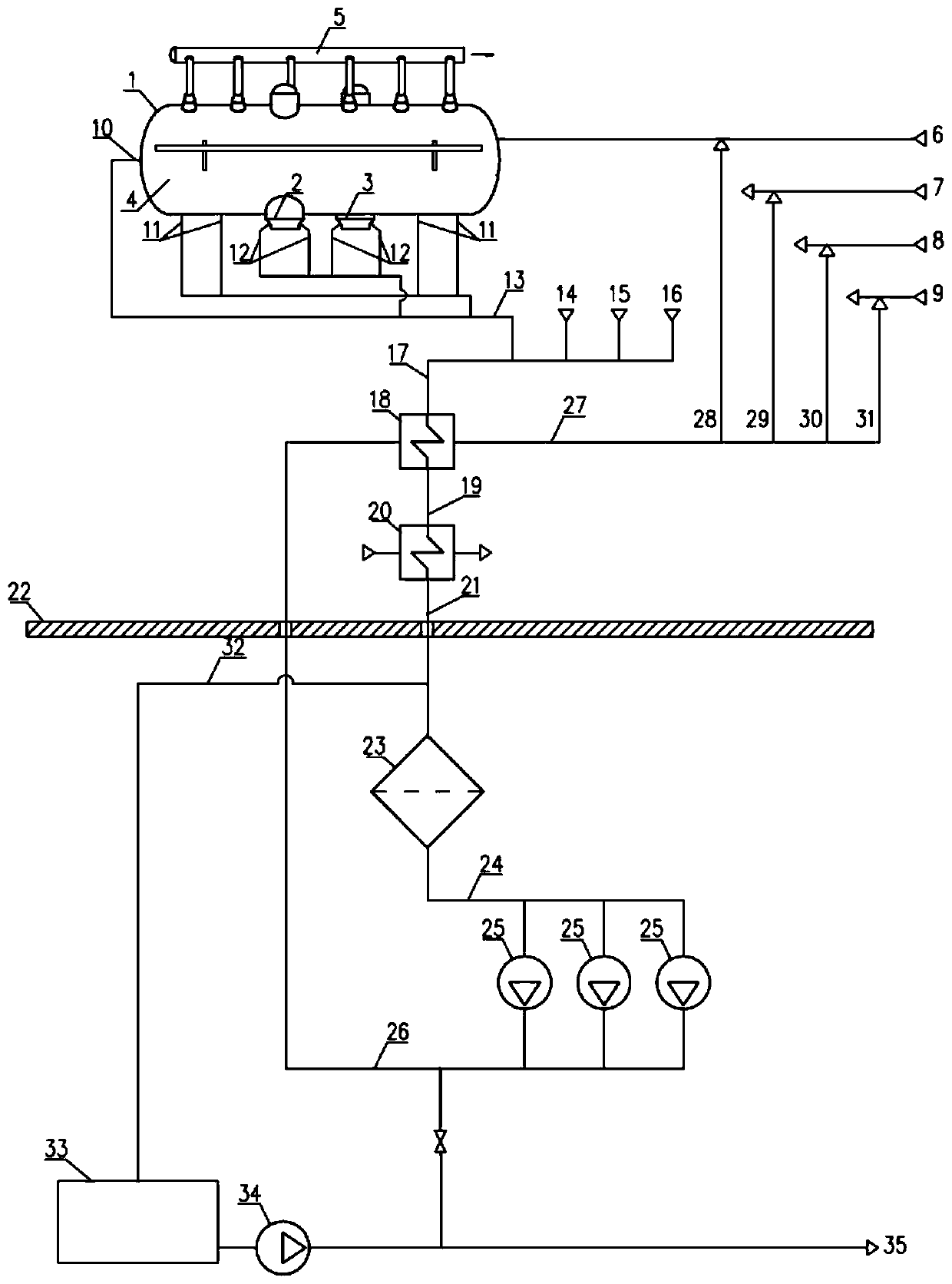

Double-loop nuclear reactor steam generating plant having a blowdown and drainage system

A technology for a steam generating device and a nuclear reactor, which is applied to the steam generation, the primary side of the steam generator, the reactor, etc., can solve the problems of increasing the normalization time of water chemical working conditions, insufficient purging water flow, increasing energy loss, etc. Effect of normalizing time, reducing energy loss, guaranteeing autonomy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The operation of the steam generating device is as follows. From the first circuit the coolant enters the "hot" collector 3 of each steam generator 1, transfers its heat to the water of the steam generator 1, leaves after cooling through the "cold" collector 2 to the inlet of the main circulation pump (not shown in the figure). Raw material steam 1 is supplied to the first, second, third and fourth steam generators 1 through feedwater supply pipes 6, 7, 8 and 9, respectively. Dry steam is taken out from the steam collector 5 of each steam generator 1, and then the steam pipeline is sent to a steam turbine (not shown in the figure).

[0027]Purging involves continuous and periodic withdrawal of part of the boiler water from the areas most likely to accumulate corrosion products, salts and sludge. The continuous and periodic purge flow is split through the purge line 10 of the salt chamber 4 of each steam generator 1 , the purge line 11 from the lower casing busbar and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com