Attapulgite adsorbent and preparation method thereof

A technology of adsorbent and attapulgite, applied in the field of attapulgite adsorbent and its preparation, can solve the problems of damage, insufficient contact area, small contact area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

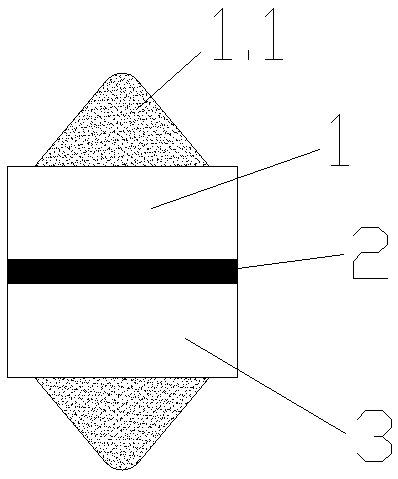

[0033] figure 1 An attapulgite adsorbent in the middle is composed of adsorbent particles. In the figure: 1. The upper part of the adsorbent particle, 1.1. The dyeing tip, 2. The bittering agent layer, and 3. The lower part of the adsorbent particle. The adsorbent particle is divided into an upper part of the adsorbent particle, a bittering agent layer and a lower part of the adsorbent particle. The bittering agent layer is arranged between the upper part of the adsorbent particle and the lower part of the adsorbent particle. The tip, the lower part of the adsorbent particles is also provided with a dyed tip, and the bittering agent layer is composed of bitter powder.

[0034] The raw materials used in the adsorbent block are by mass: 80 parts of attapulgite, 20 parts of medical stone powder, 10 parts of starch, 12 parts of carrageenan, 6 parts of lignocellulose, 4 parts of pigment powder, and 2 parts of bittering agent powder;

[0035] In this example, the pigment powder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com