Machining method of small-caliber ball valve

A processing method and small-diameter technology, applied in the processing field of small-diameter ball valves, can solve the problems of insufficient strength, unable to finish spherical surface, unable to meet the processing of small-diameter spheres, etc., to achieve the effect of saving cost and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

[0035] The present invention proposes a processing method for small-diameter ball valves, which can be applied to the processing of a series of small-diameter ball valves such as DN6 to DN40. The sphere can be realized by using the existing general ball cart without additional investment in other equipment.

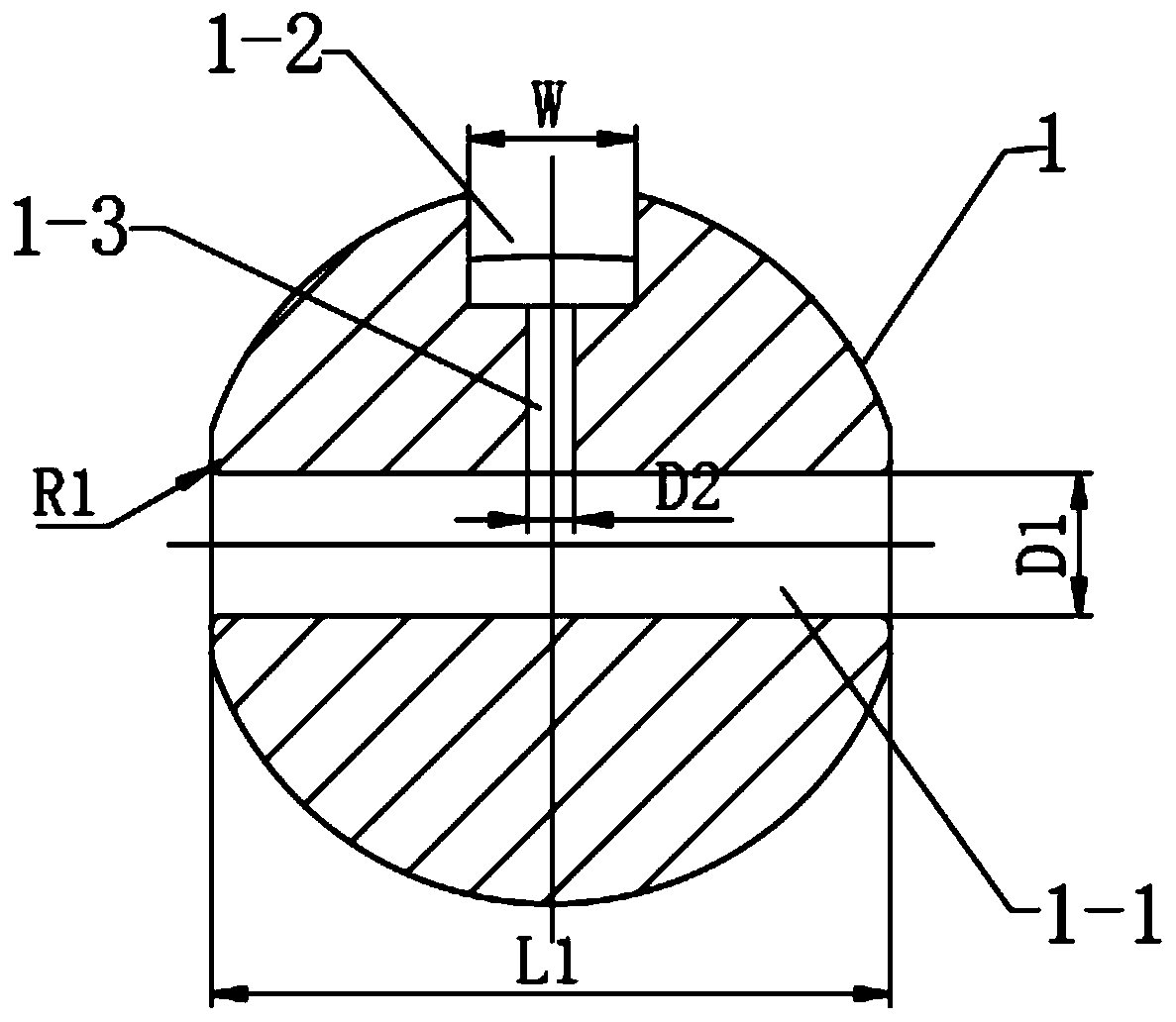

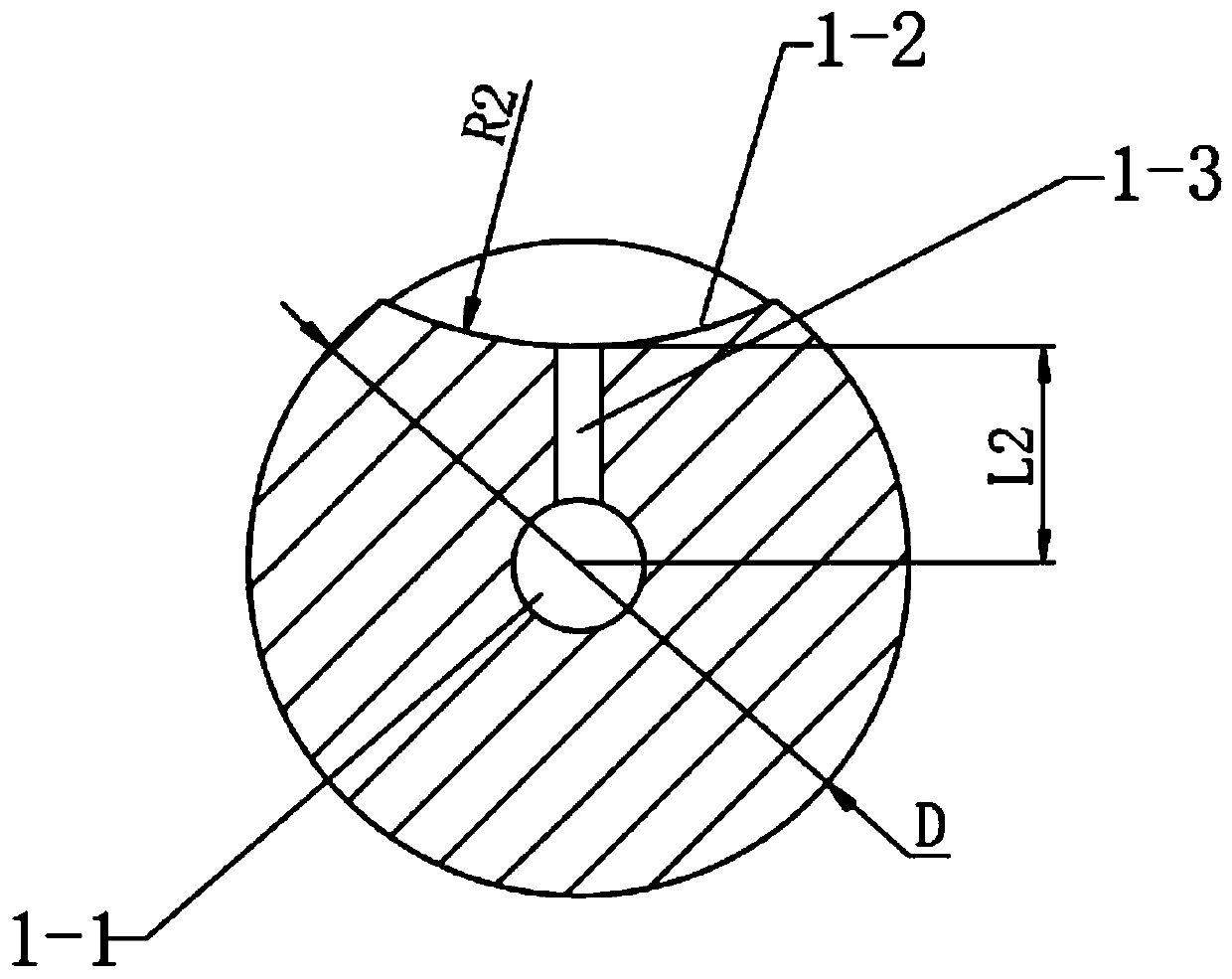

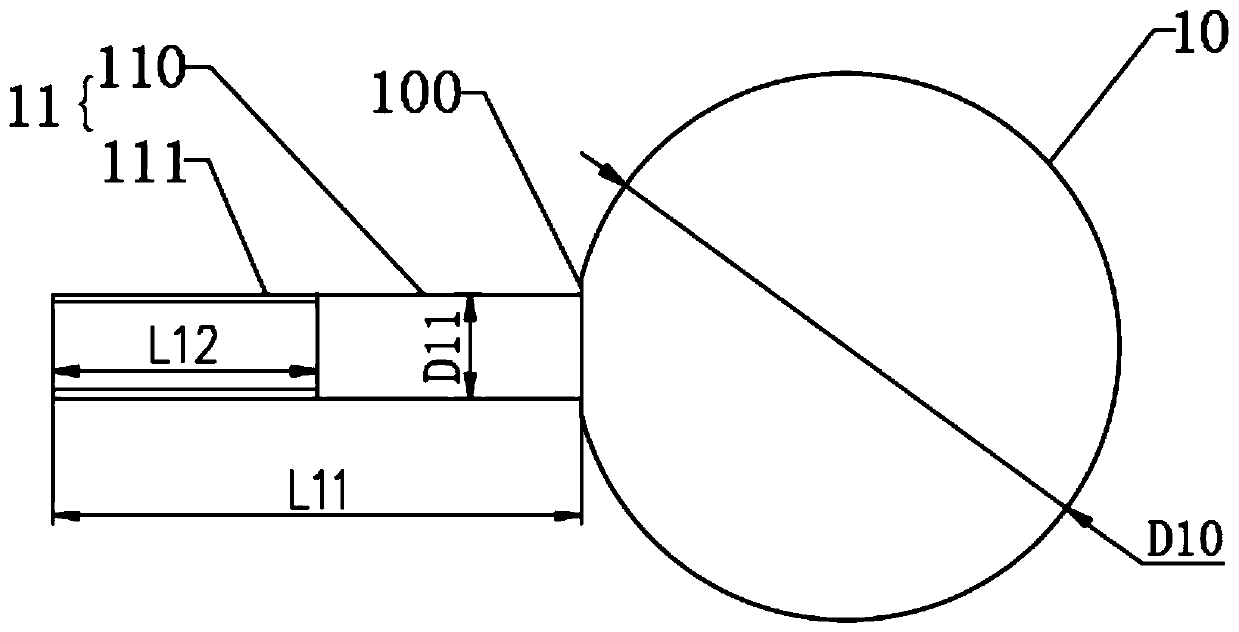

[0036] Please refer to Figure 1 to Figure 7 . The technical solution of the present invention will be described in detail below with DN6 as an example; , crescent groove 1-2 and vent hole 1-3, wherein, the diameter D of described sphere 1 is 30mm; The length L1 of its inner hole 1-1 is 28.5mm, and diameter D is 6mm, and the orifice of inner hole is opened There is a chamfer structure, the radius R1 of the chamfer is 0.5mm; the groove width W of the crescent groove 1-2 is 7cm, the radius of the arc surface R2=20mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com