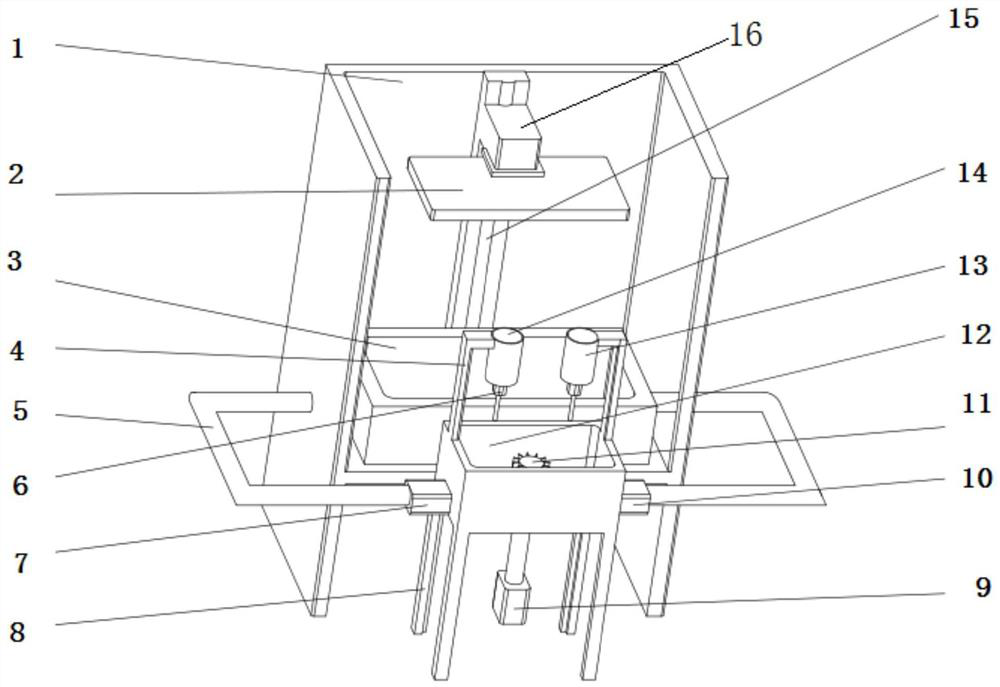

A light curing gradient material forming device and method

A technology of light-curing molding and gradient materials, which is applied in the processing of accessories of main materials, additive processing, manufacturing tools, etc. It can solve the problems that cannot be carried out in the laboratory, it is difficult to obtain large-size materials, and the bonding strength of coatings is not high. , to achieve the effect of improving performance requirements, simple structure, and simple molding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040]When printing starts, take 100g of light-curable molding resin and 10g of alumina and mix in the mixing tank to obtain the initial concentration of light-curable molding material, and then use the second circulation pump to pump the initial concentration of light-curable molding material into the light-curable tank. The printed model is gradually light-cured and formed, and the quality of the material consumed to complete the first stage of gradient material molding is Ag. The remaining light-cured molding material is pumped into the mixing tank by the first circulation pump, and the light-cured molding is consumed according to the first stage of the printing process. Material quality, the remaining material quality (110-A)g can be obtained, where the light-curing molding resin is Alumina is At this time, the concentration of the remaining material is the initial concentration. According to the density of the photocuring molding material required for the next stage of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com