Chip transferring device

A chip transfer and chip technology, applied in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of low transfer efficiency and high production costs, and achieve the effect of improving transfer efficiency and reducing transfer costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

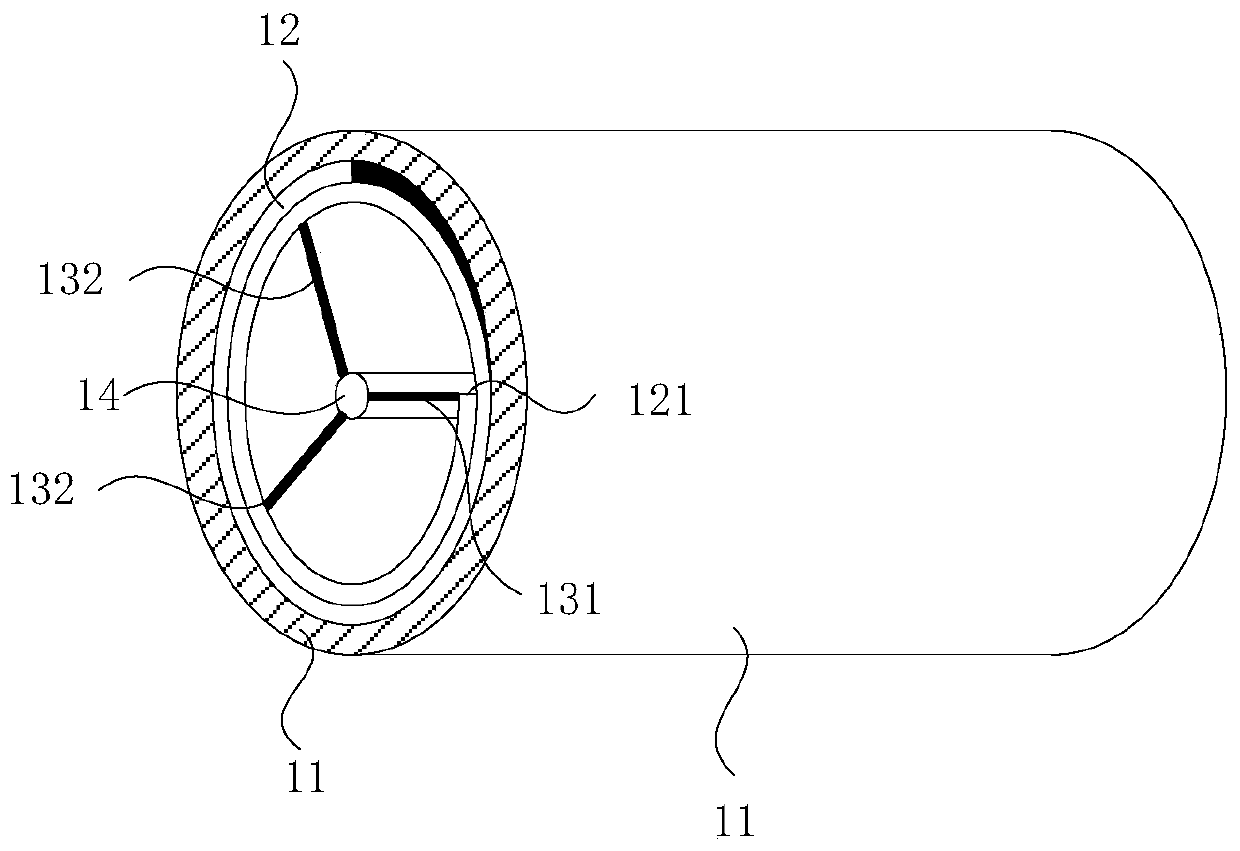

[0050] figure 1 It is a schematic diagram of the chip transfer device provided by Embodiment 1 of the present invention. The chip transfer device of this embodiment specifically includes: an elastic body 11 , a first rolling body 12 , a first support portion, and a first set of rods 14 .

[0051] The elastic body 11 is hollow and cylindrical, and is used for absorbing the cut chips. Specifically, the elastic body 11 is made of rubber and has a uniform hollow tubular shape with a certain expansion ability in the horizontal and vertical directions. The elastic layer also includes an adhesive layer on the outside, and the adhesive layer is used to absorb the cut chips.

[0052] The first rolling body 12 is hollow inside and is cylindrical, and is placed inside the elastic body 11 for supporting the cylindrical elastic body 11 and adjusting the radius of the elastic body 11. Specifically, the first rolling body 12 is made of The rigid material is curled to form a helix, and the a...

Embodiment 2

[0068] Figure 8 For the chip transfer device provided in this embodiment, compared with the chip transfer device in Embodiment 1, the chip transfer device in this embodiment further includes: at least one second rolling body, at least one second supporting part, at least one second set of rods .

[0069] At least one second rolling body 22 is hollow inside and is cylindrical, similar to the first rolling body 12 such as Figure 9 The nested sliding connection shown is used to support the cylindrical elastic body and adjust the length and radius of the elastic body 11 . Specifically, the second rolling body is coiled by a rigid material to form a spiral shape, and the appearance of the second rolling body is in the shape of a circular roll. Sliding and stretching between the first roll body 12 and the second roll body 22 can adjust the total length of the first roll body 12 and the second roll body 22 to adjust the length of the elastic body.

[0070] At least one second su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com