Ultrahigh saturation flux density manganese-zinc ferrite material and preparation method thereof

A manganese-zinc ferrite and magnetic flux density technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem of low saturation magnetic flux density and achieve the effect of optimizing the sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

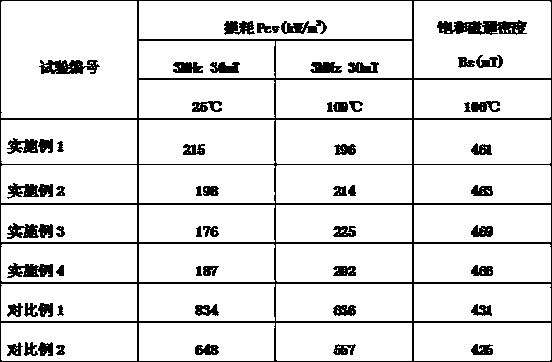

Examples

Embodiment 1

[0015] Embodiment 1: A manganese-zinc ferrite material with an ultra-high saturation magnetic flux density is composed of a main component and an auxiliary component, and the main component is Fe 2 o 3 :55.25mol%, ZnO: 3.2mol%, Co 2 o 3 : 0.20mol%, the rest is MnO; secondary component Nb 2 o 5 :0.02wt%, CaCO 3 :0.05wt%, NiO:0.02wt%, V 2 o 5 :0.02wt%, SiO 2 : 0.008wt%, TiO 2 :0.01wt%, Ta 2 o 5 : 0.02wt%, the above secondary components are based on Fe 2 o 3 , ZnO, MnO and Co 2 o 3 The total weight percentage is calculated.

[0016] A preparation method for producing the high-frequency, wide-temperature, low-loss, ultra-high saturation magnetic flux density manganese-zinc ferrite material described in Example 1, comprising the steps of:

[0017] 1) Ingredients: According to the main formula Fe 2 o 3 , ZnO, Co 2 o 3 , MnO ratio was weighed and mixed sanding, sanding time is 15min;

[0018] 2) Pre-burning: Pre-burn the mixed powder at 900°C and keep it warm for...

Embodiment 2

[0023] Example 2: A manganese-zinc ferrite material with an ultra-high saturation magnetic flux density, which is composed of a main component and an auxiliary component, and the main component is Fe respectively 2 o 3 :55.5mol%, ZnO: 3.5mol%, Co 2 o 3 : 0.15mol%, the rest is MnO; secondary component Nb 2 o 5 :0.04wt%, CaCO 3 :0.05wt%, NiO:0.03wt%, V 2 o 5 :0.03wt%, SiO 2 : 0.01wt%, TiO 2 :0.03wt%, Ta 2 o 5 : 0.01wt%, the above secondary components are based on Fe 2 o 3 , ZnO, MnO and Co 2 o 3 The total weight percentage is calculated.

[0024] A preparation method for making the ultrahigh saturation magnetic flux density MnZn ferrite material described in Example 2, comprising the steps of:

[0025] 1) Ingredients: According to the main formula Fe 2 o 3 , ZnO, Co 2 o 3 , MnO ratio to weigh and mix sanding, sanding time is 25min;

[0026] 2) Pre-burning: pre-burn the mixed powder, the pre-burning temperature is 1000 ℃, keep warm for 2 hours;

[0027] 3) S...

Embodiment 3

[0031] Embodiment 3: A manganese-zinc ferrite material with an ultra-high saturation magnetic flux density is composed of a main component and an auxiliary component, and the main component is Fe respectively 2 o 3 :56.2mol%, ZnO: 2.5mol%, Co 2 o 3 : 0.10mol%, the rest is MnO; secondary component Nb 2 o 5 :0.01wt%, NiO:0.05wt%, CaCO3 :0.08wt%, V 2 o 5 :0.01wt%, SiO 2 0.005wt%, TiO 2 :0.05wt%, Ta 2 o 5 : 0.02wt%, the above secondary components are based on Fe 2 o 3 , ZnO, MnO and Co 2 o 3 The total weight percentage is calculated.

[0032] A method for preparing the ultra-high saturation magnetic flux density manganese-zinc ferrite material described in Example 3, comprising the steps of:

[0033] 1) Ingredients: According to the main formula Fe 2 o 3 , ZnO, Co 2 o 3 , MnO ratio was weighed and mixed sanding, sanding time is 15min;

[0034] 2) Pre-burning: Pre-burn the mixed powder at 1050°C for 2 hours;

[0035] 3) Sanding: add the additives to the calcine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com