Wide-temperature ultralow-loss manganese zinc ferrite material and preparation method thereof

A manganese-zinc ferrite and ultra-low technology are applied in the field of wide-temperature and ultra-low loss manganese-zinc ferrite materials and their preparation, and can solve the problems of high and low temperature loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

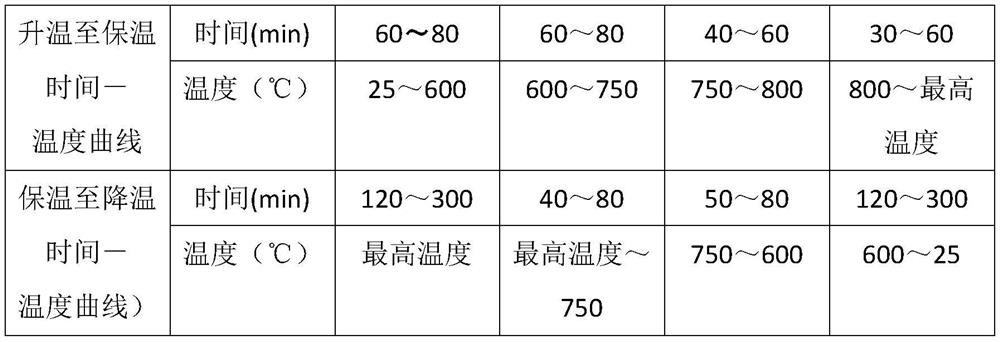

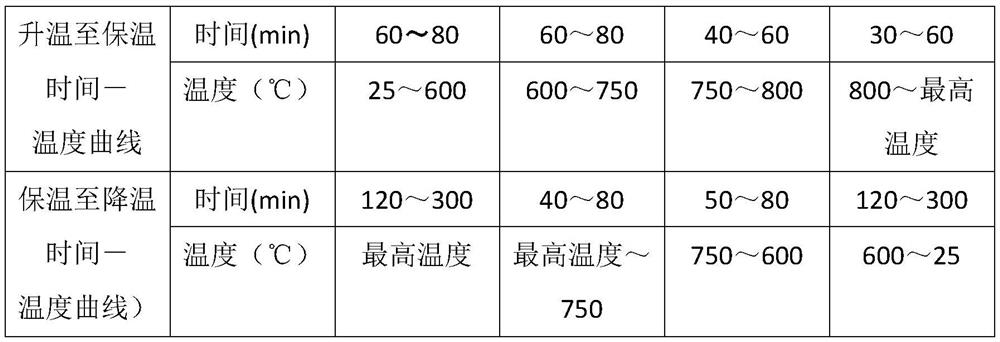

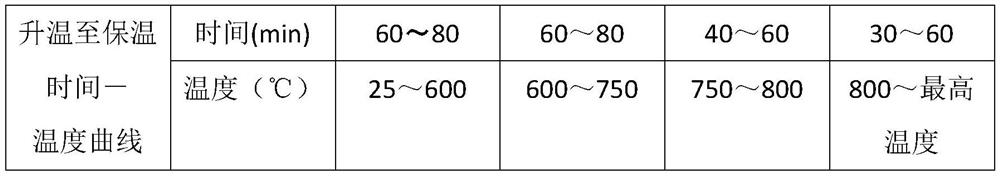

Method used

Image

Examples

Embodiment 1

[0039] A wide-temperature ultra-low loss manganese-zinc ferrite material and a preparation method thereof. It is composed of main components and auxiliary components, among which, the main component and its content are calculated as the percentage of oxides: Fe 2 o 3 is 50.55mol%, ZnO is 11.05mol%, and the rest is MnO, the total amount of the main component formula is 100%; the auxiliary components by accounting for the total weight of the main component are: CaO 450ppm, ZrO 2 250ppm, Co 2 o 3 4000ppm, SiO 2 30ppm, Nb 2 o 5 300ppm, SnO 2 550ppm.

[0040] The specific preparation process of the soft magnetic ferrite material is:

[0041] The specific preparation process of the soft magnetic ferrite material is:

[0042](3) Batching vibrating mill mixing: weigh according to the ratio of the main components of the raw materials, put each raw material into a vibrating mill and vibrate milling and mixing, and the mixing time is 0.8 hours;

[0043] (4) Pre-burning: pre-...

Embodiment 2

[0058] A wide-temperature ultra-low loss manganese-zinc ferrite material and a preparation method thereof. It is composed of main components and auxiliary components, among which, the main component and its content are calculated as the percentage of oxides: Fe 2 o 3 is 50.95mol%, ZnO is 10.85mol%, and the rest is MnO, the total amount of the main component formula is 100%; the auxiliary components by accounting for the total weight of the main component are: CaO 400ppm, ZrO 2 200ppm, Co 2 o 3 3800ppm, SiO 2 40ppm, Nb 2 o 5 250ppm, SnO 2 250ppm, TiO 2 300ppm.

[0059] The specific preparation process of the soft magnetic ferrite material is:

[0060] The specific preparation process of the soft magnetic ferrite material is:

[0061] (5) Batching vibration grinding mixing: weigh according to the ratio of the main components of the raw materials, put each raw material into the vibration grinding machine and mix the mixing, the mixing time is 0.6 hours;

[0062] (6) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com