Preparation method of aluminum nitride powder with dense morphology

A technology of aluminum nitride and morphology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as difficult heat conduction network chains, affecting the thermal conductivity of finished products, affecting the preparation process of thermal conductive adhesives, etc., and achieves great application prospects , Improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

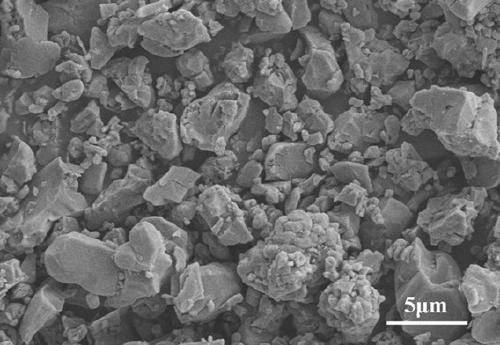

Embodiment 1

[0015] Dry mix high-purity Al powder and 45wt% AlN evenly, with 15% NH of the total amount of Al and AlN 4 Cl was put into the graphite ark together, placed in a vacuum sintering furnace, fed with nitrogen and nitrided at 1300°C for 2h. The obtained AlN block sample was crushed and ball milled to shape at 60 MPa, and then put into a vacuum sintering furnace for heat treatment at 1800°C for 1 hour. The whole heat treatment process was always protected by nitrogen gas. The aluminum nitride powder obtained after crushing and ball milling had large particle size and dense particles. It is the material of choice for thermally conductive adhesive fillers.

Embodiment 2

[0017] Dry mix high-purity Al powder and 30wt% AlN evenly, with 10% NH in the total amount of Al and AlN 4 Cl was put into the graphite ark together, placed in a vacuum sintering furnace, fed with nitrogen and nitrided at 1100°C for 2h. The obtained AlN block sample was crushed and ball milled to shape at 60MPa, and then put into a vacuum sintering furnace for heat treatment at 1750°C for 2 hours. The whole heat treatment process was always protected by nitrogen gas. The aluminum nitride powder obtained after crushing and ball milling had large particle size and dense particles. It is the material of choice for thermally conductive adhesive fillers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com