Chromium-containing cobalt-based high-temperature alloy and application thereof

A high-temperature alloy, cobalt-based technology, applied in the field of alloys, can solve the problems of lack of coherent strengthening mechanism and no major progress in high-temperature performance, and achieve the effect of enhancing thermal corrosion resistance and tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

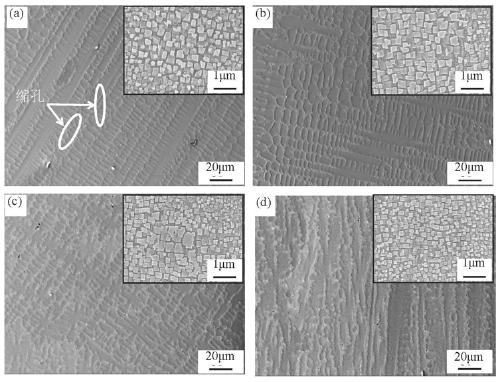

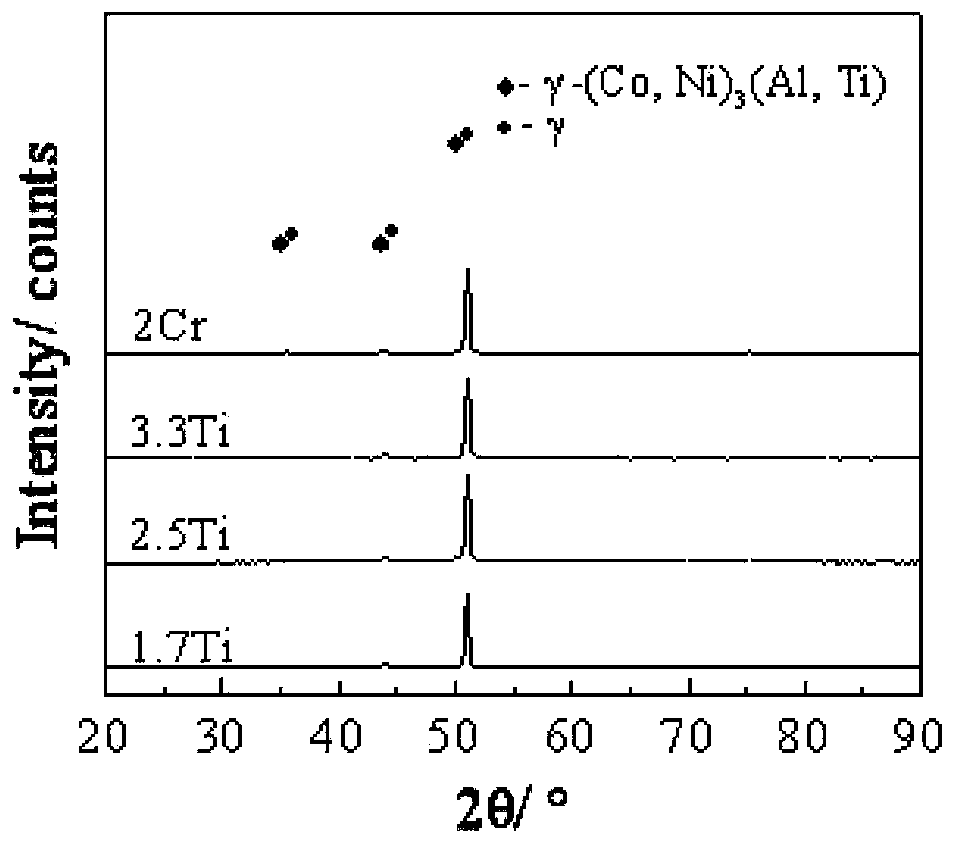

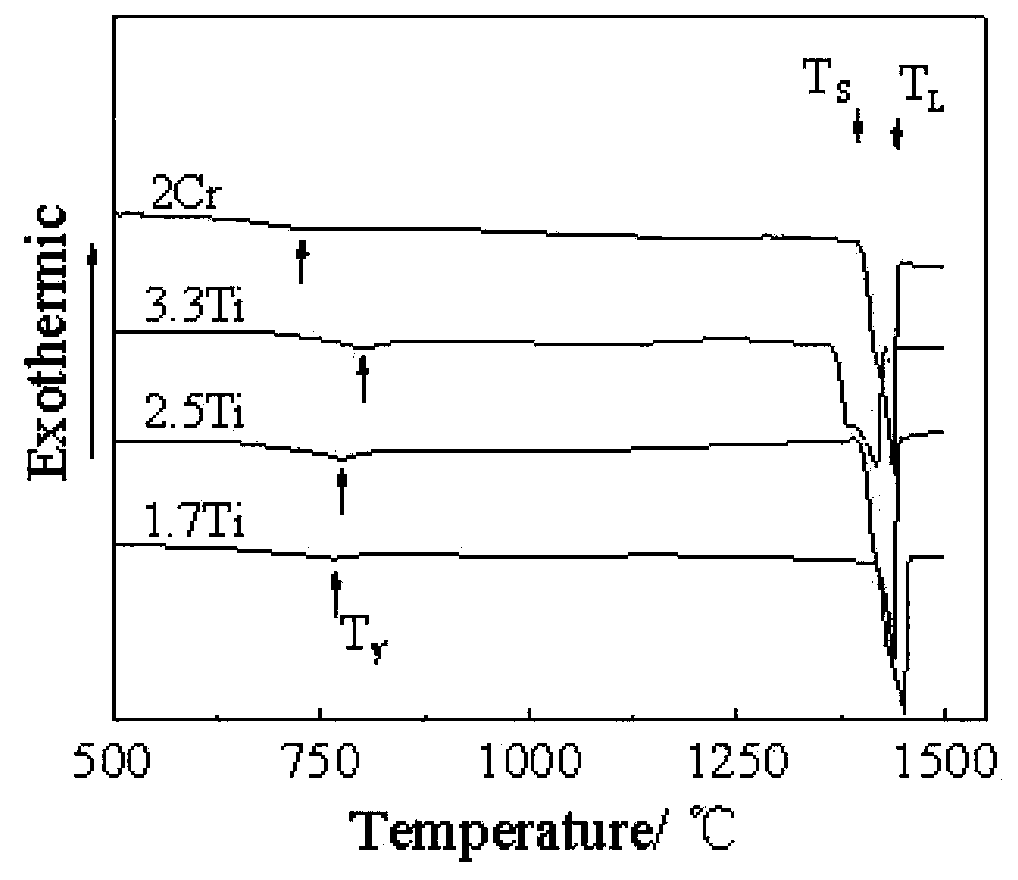

[0051] The present invention will be further described below in conjunction with specific implementation cases, but the present invention is not limited to these embodiments, and examples of said embodiments are shown in the accompanying drawings.

[0052] This embodiment prepares a chromium-cobalt-based superalloy, which is composed of Cr, Co, Ni, Al and Ti elements, and the atomic percentage content of Cr is 2 at.%, Ni is 30 at.%, Al is 7.5 at.%, Ti %, the balance is Co; the sum of the atomic percentages of Al and Ti is not more than 10 at.%, and the sum of the atomic percentages of Cr, Co, Ni, Al and Ti is 100 at. %;

[0053] In this example, four cobalt-based superalloy ingots were prepared, followed by heat treatment, and the structure and performance of the chromium-containing cobalt-based superalloy and the other three cobalt-based superalloys were compared and analyzed:

[0054] In this example, four cobalt-based superalloy ingots were prepared by using a vacuum induc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com