Multifunctional protective cylinder suitable for sludge bottom layer and construction method using protective cylinder

A multi-functional, silt layer technology, applied in the direction of basic structure engineering, construction, sheet pile walls, etc., can solve problems such as collapse, hindering the pulling out of steel casings, and disturbance of the inner wall of boreholes, etc., to reduce weight and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

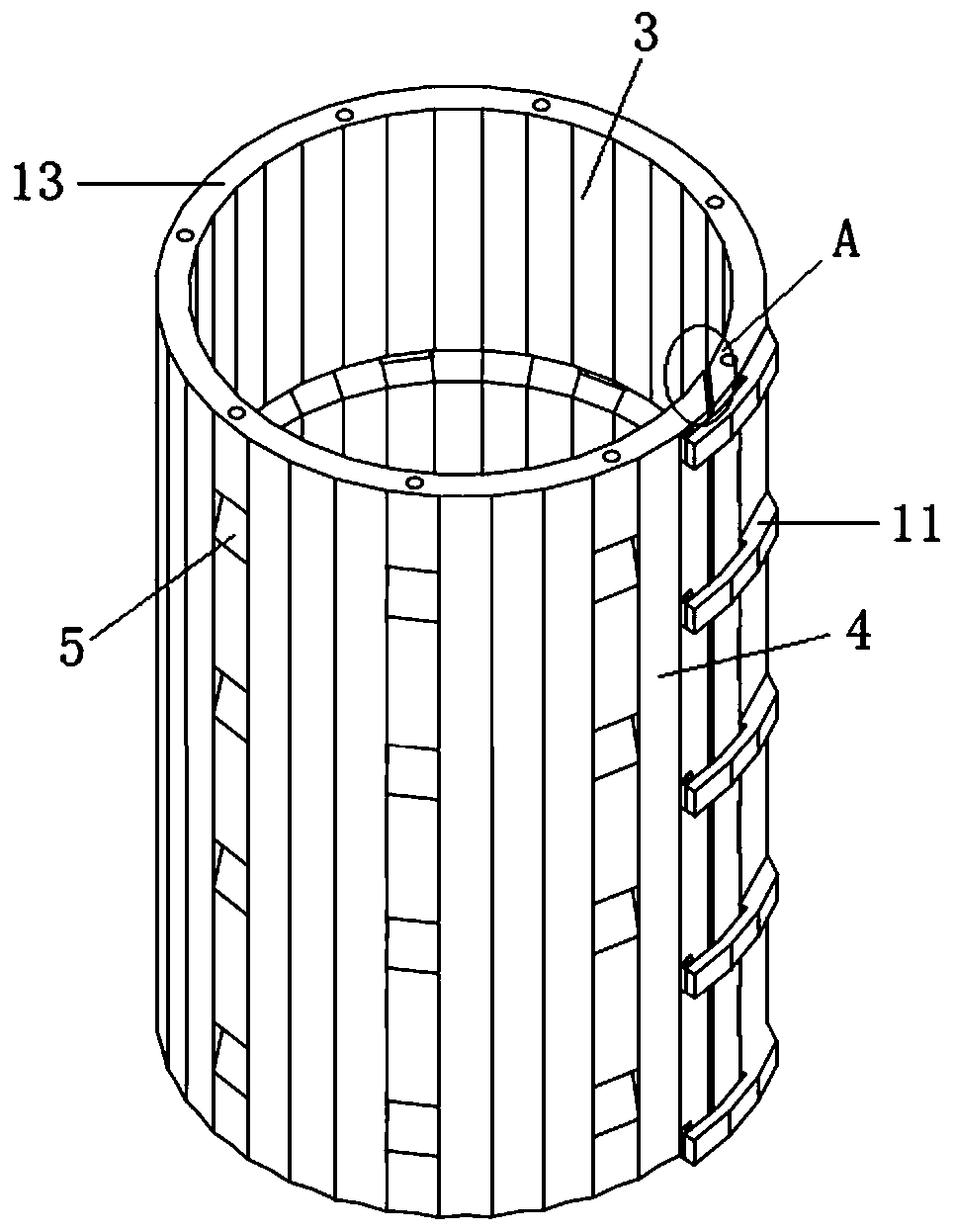

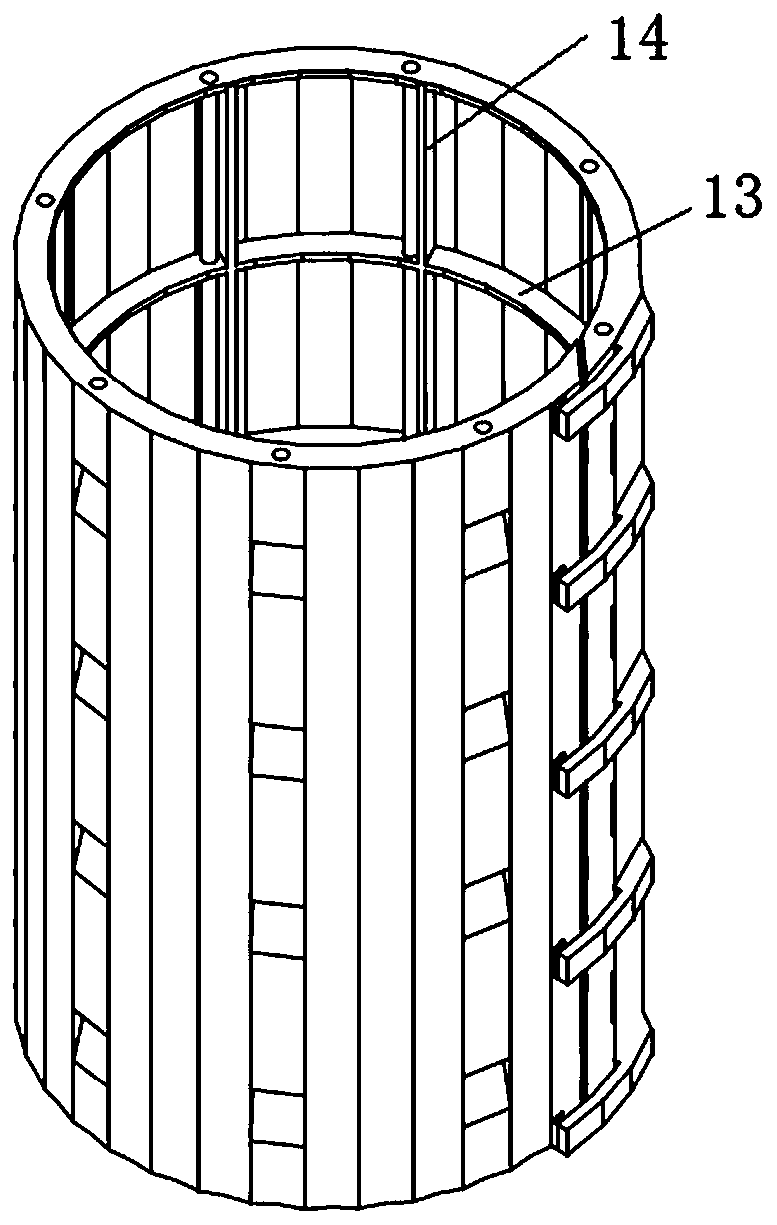

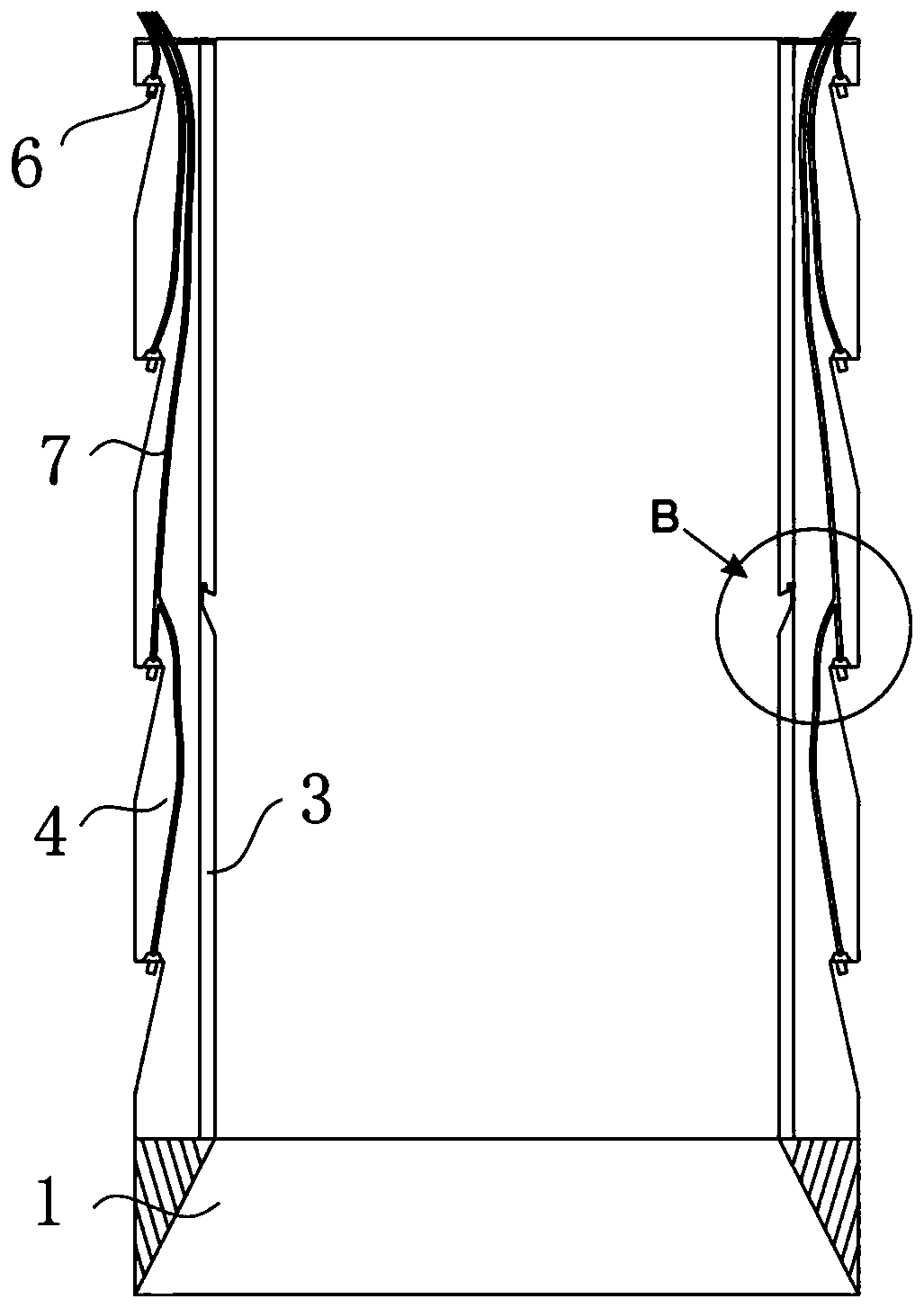

[0021] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0022] Such as figure 1 and figure 2 As shown, the multifunctional casing of the present invention is applicable to the bottom layer of mud, and it comprises a cylindrical shape, a cylinder with unclosed edges and a gap, a water jet assembly arranged in the side wall of the cylinder, and a water jet assembly arranged on the side of the cylinder. The pull button assembly on the wall is located at the notch of the barrel and can cover the notch, that is, the pull button assembly is arranged on the side walls on both sides of the notch. The radial cross-section of the notch is a symmetrically arranged triangle. The two ends of the notch are divided into a first end and a second end. Buckle components are distributed on the side walls of the first end and the second end, and are used to keep the first end and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com