Device and method for treating kitchen waste

A technology for processing equipment and kitchen waste, applied in water supply equipment, indoor sanitary piping equipment, buildings, etc., can solve the problems of unfavorable screening efficiency, large crushing load, and no selectivity in crushing, and achieves improved screening effect and high cutting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

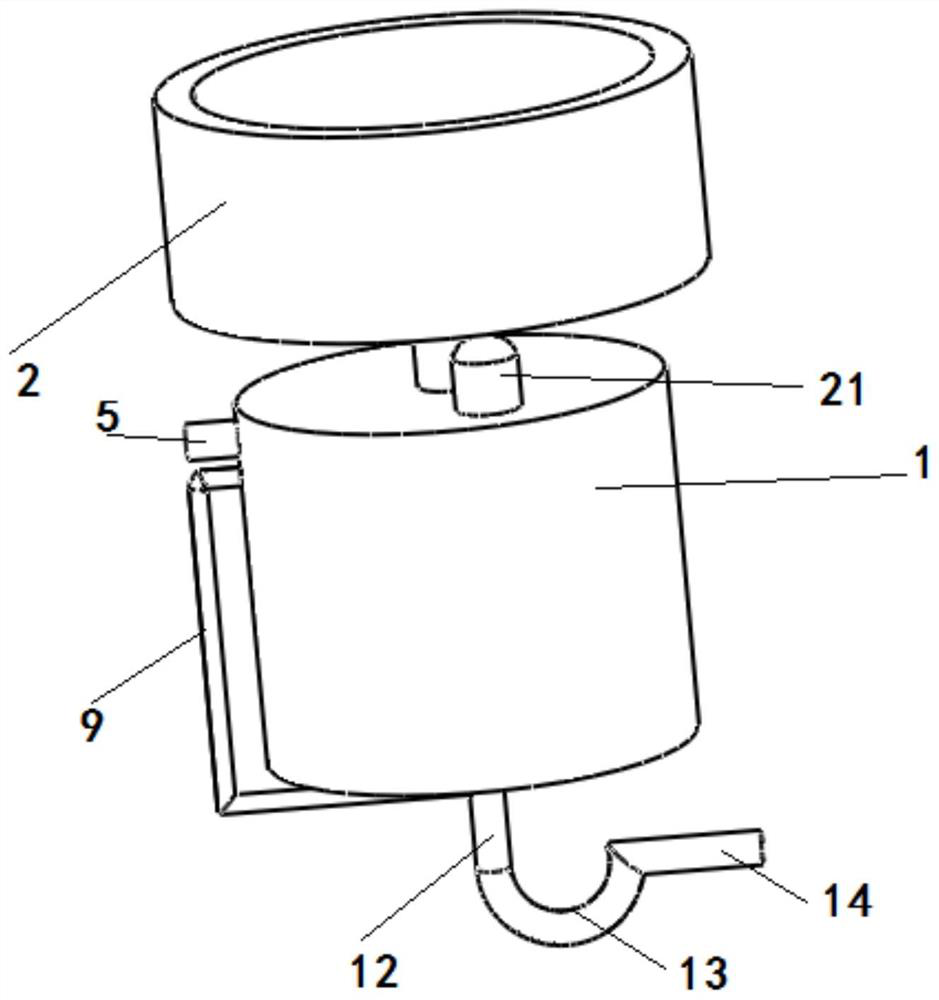

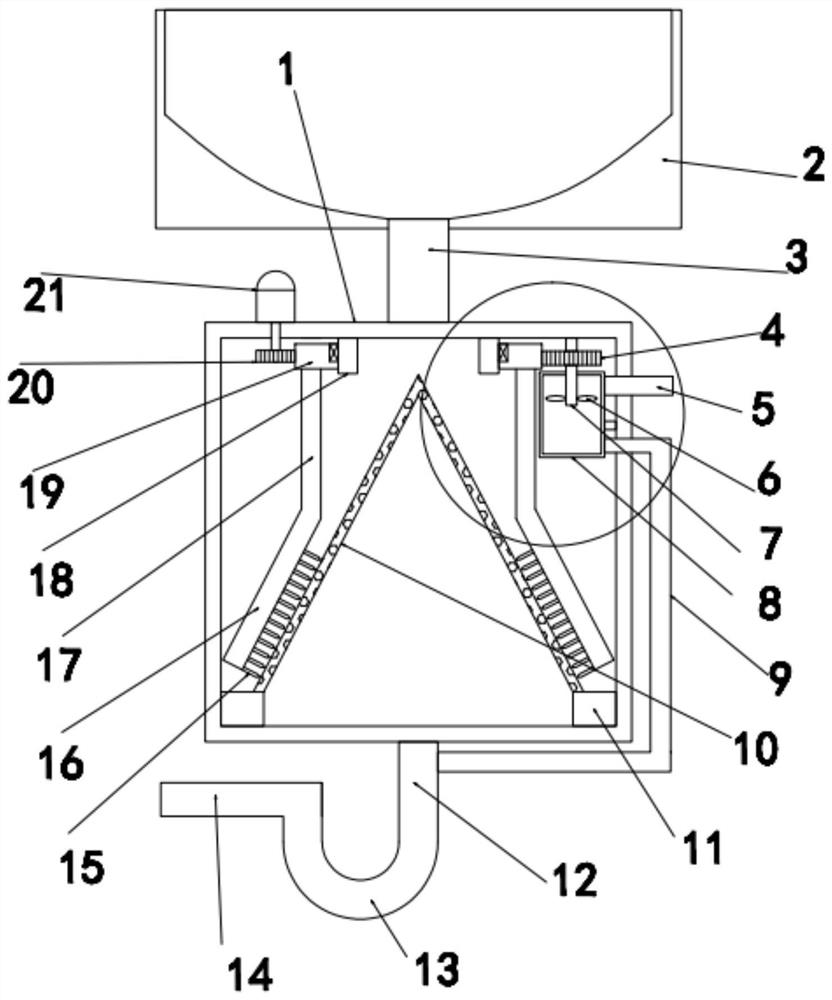

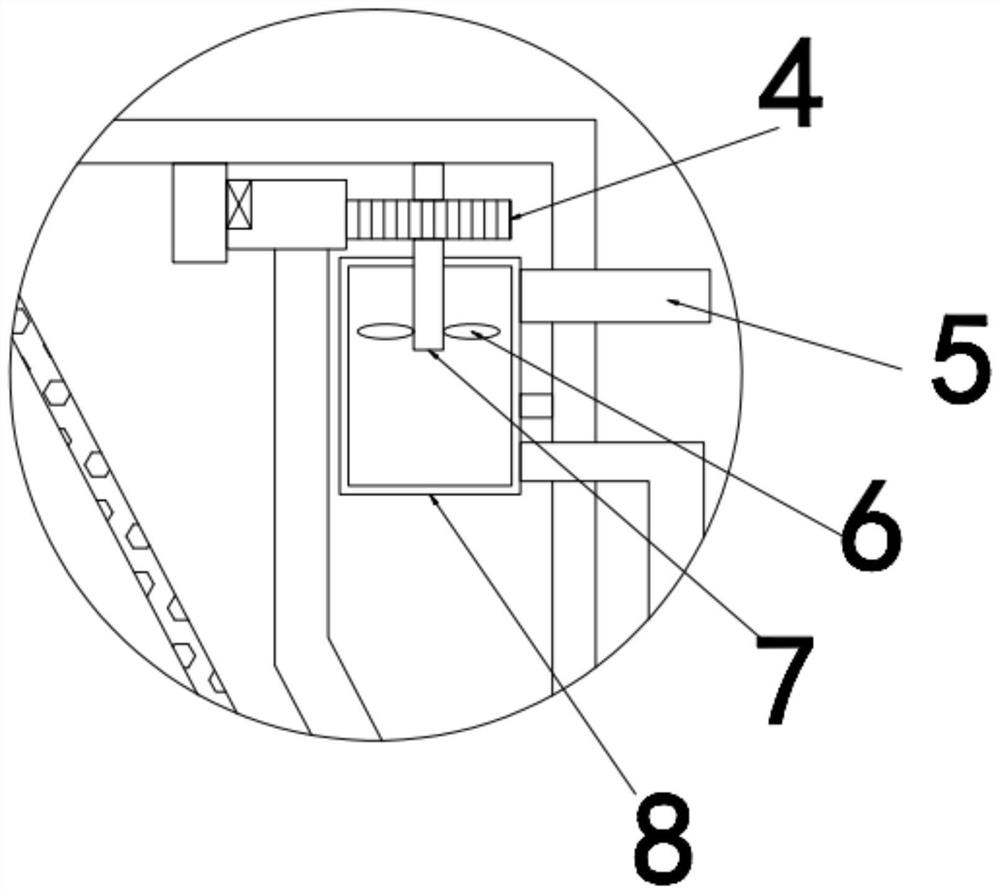

[0025] see Figure 1-3 , in an embodiment of the present invention, a kitchen waste treatment device includes a water receiving pool 2 for cleaning kitchen utensils, the discharge end of the lower end of the water receiving pool 2 communicates with the upper end of the treatment box 1 at the upper end of the treatment box 1 through a communication pipe 3, and the The drain end of the lower end of the treatment box 1 is provided with a drainpipe 12, the lower end of the drainpipe 12 is connected to a U-shaped pipe 13 for buffering clean water to realize a water seal, and the other end of the U-shaped pipe 13 is connected to a sewage conduit 14. There is a cutting part for sorting and cutting the materials, and the inside of the processing box 1 is provided with a filter screen 10 for filtering the materials. The filter screen 10 is a conical filter structure, and the filter screen 10 is coaxially arranged with the connecting pipe 3 , the lower end of the filter screen 10 is pro...

Embodiment 2

[0033] The difference from Embodiment 1 is that the inner wall of the air extraction box 8 is provided with an ultraviolet disinfection lamp for disinfection and sterilization, and a waterproof cover is provided outside the ultraviolet disinfection lamp.

[0034] The working principle of the present invention is: when the material falls along the connecting pipe 3, the material will slide down along the top of the conical filter screen, the qualified material will pass through the filter screen 10 during the sliding process, and the unqualified material will pass through the filter screen 10 along the cone-shaped filter screen. Shape filter screen 10 slides to the bottom, and under the effect of drive motor 21, drive gear 20 drives suspender 17 to rotate through driven gear 19, and suspender 17 drives cutting knife 15 to rotate, thereby the material that cannot pass through filter screen 10 is cut Cut until the material passes through the filter screen 10, avoiding the problem ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com