Assembly type buckling-restrained brace with replaceable inner core

An anti-buckling support and assembled technology, which is applied in the direction of earthquake-proof, protective buildings/shelters, building components, etc., can solve the problems of overall instability, difficult support, waste, etc. of the connecting section, and achieve reduced transportation and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

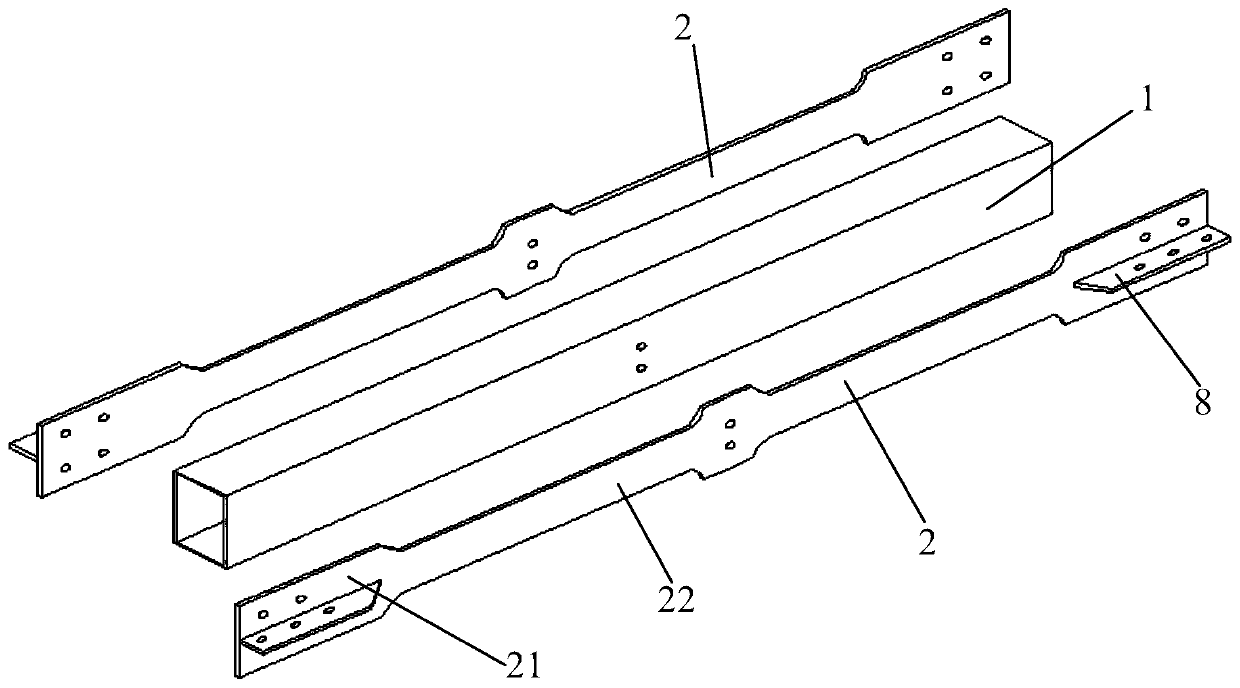

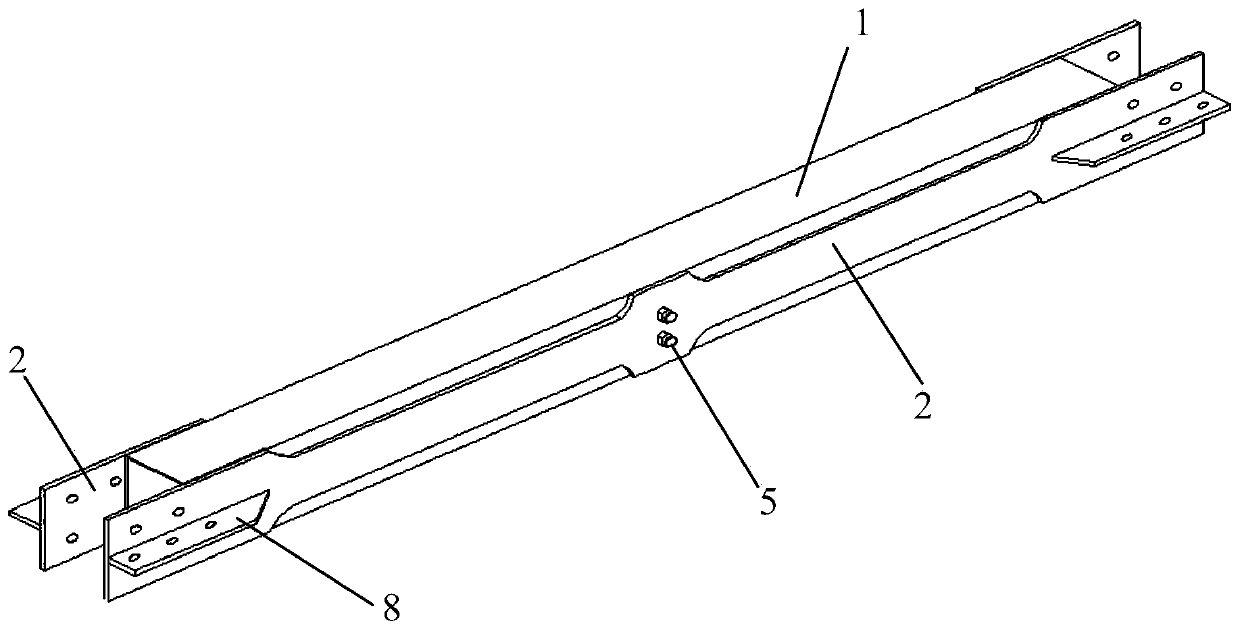

[0054] The energy-dissipating inner core board 2 can be a straight-shaped core board, including two connecting sections 21 and an energy-dissipating section 22. Variable cross-section processing is adopted, and the variable cross-section is processed in an arc shape to avoid stress concentration; both ends of the energy-dissipating core plate are welded with horizontal reinforcing ribs;

[0055] Rectangular steel pipes can be used for the outer restraint 1, and the design length should be greater than the length of the energy-dissipating inner core plate;

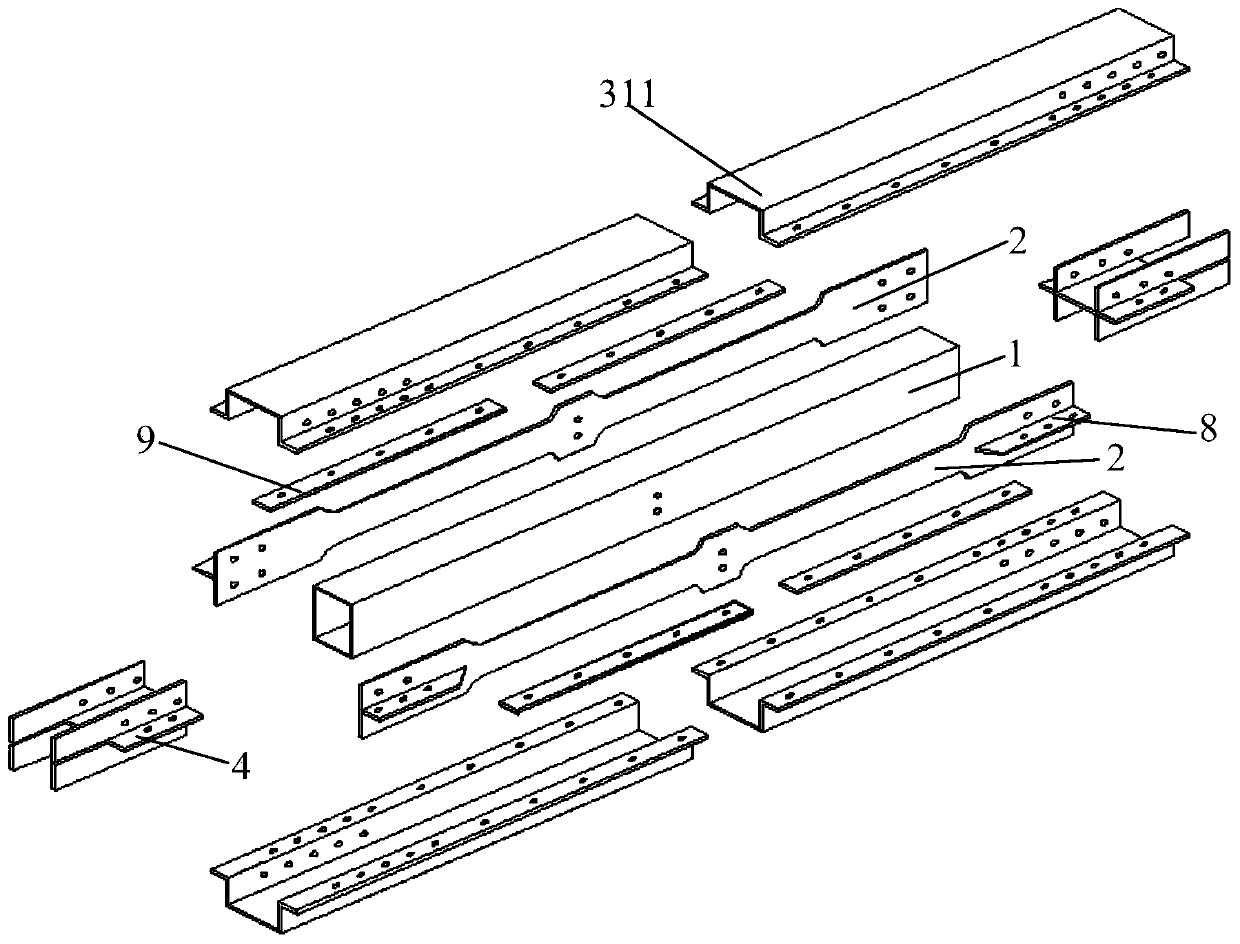

[0056] The zigzag plate can be welded by channel steel and steel plate, or pressed by steel plate. It has a number of holes along the longitudinal edge of the support, and every two zigzag plates form a fastening piece. And after the fastening parts are assembled, it should be ensured that there should be a gap of 1-3mm between the energy-dissipating inner core board and the outer restraint parts, and between the inner rest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com