Power testing device and method for aircraft gun hydraulic system

A technology for hydraulic system and power testing, which is applied in the testing of fluid pressure actuation systems, fluid pressure actuation devices, mechanical equipment, etc., can solve problems such as the inability to meet the power testing requirements of artillery systems, and achieves convenient disassembly and assembly and good reference value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention, but should not be construed as limiting the present invention.

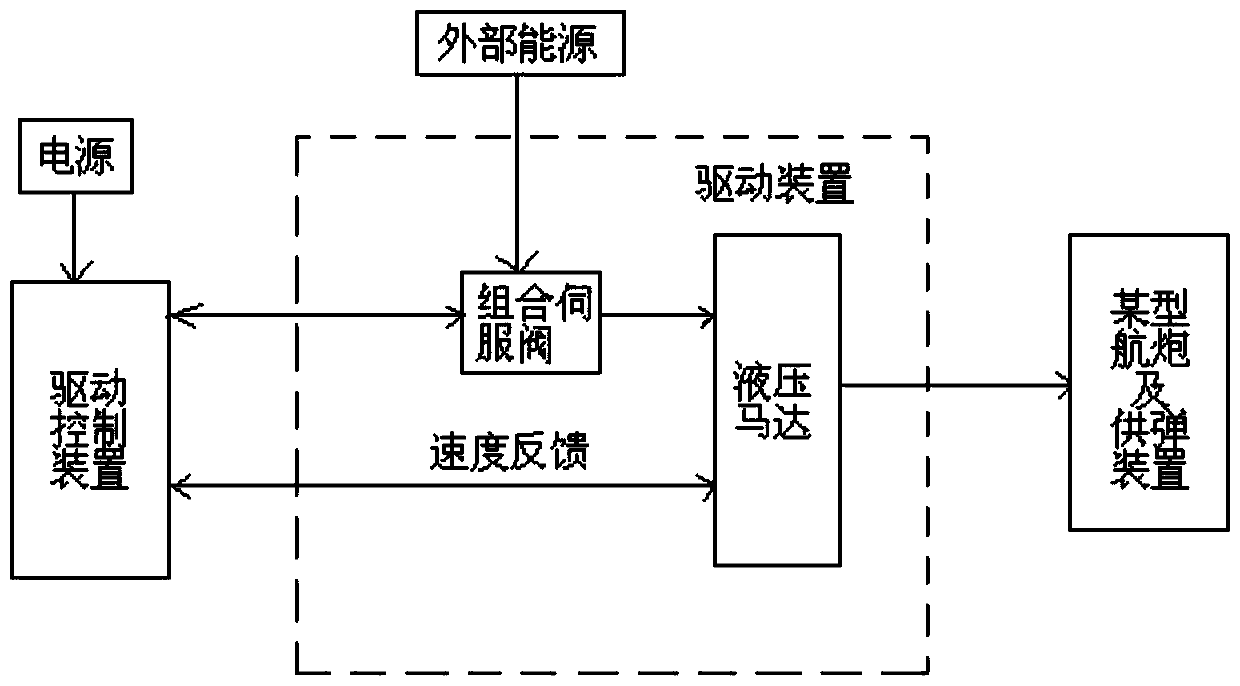

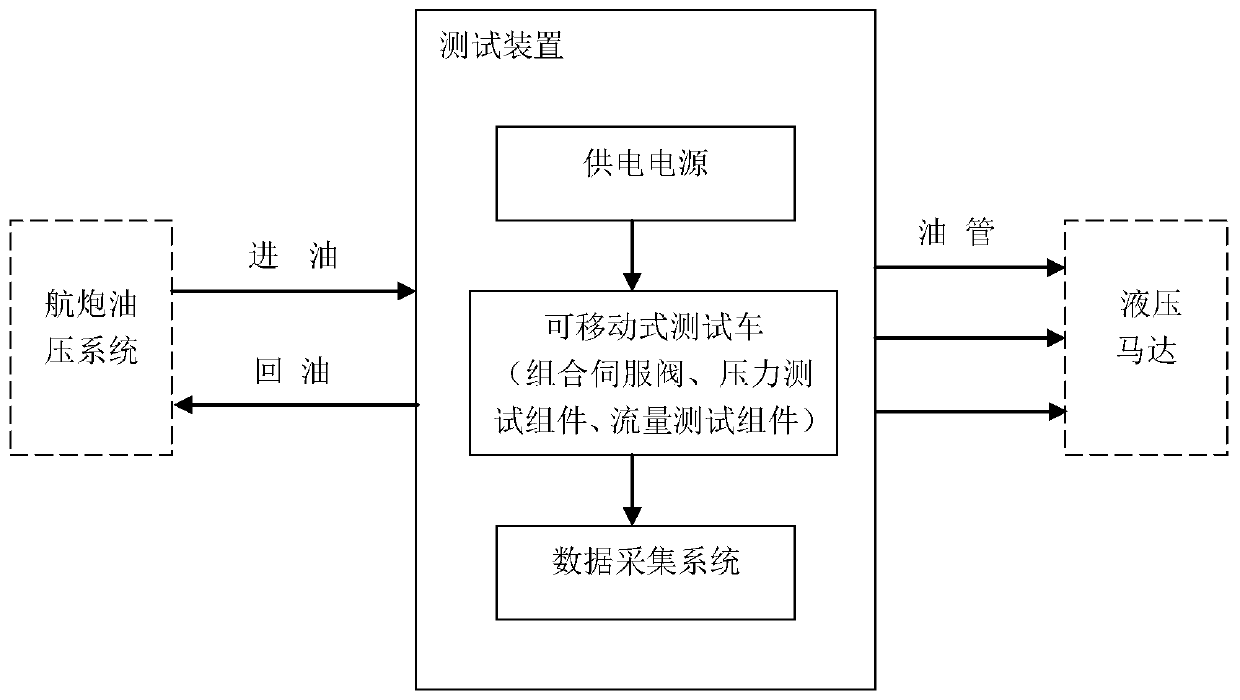

[0049] Reference figure 1 with 5 , The present invention is a power test device for a hydraulically driven aerial gun system including a movable test vehicle, a hydraulic pipeline, a power supply, and a data acquisition system; wherein, the movable test vehicle includes a combined servo mounted on the cart Valve 1, servo valve oil inlet valve block 2, servo valve oil return port valve block 10, motor drain port valve block 7, servo valve oil inlet transition valve block 6, servo valve oil return transition valve block 9, pressure test component And flow test components; one end of the combined servo valve 1 is connected to the aircraft gun hydraulic system through a hydraulic pipe, the other end is connected to a hydraulic motor through a hydraulic pipe, and is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com